- Your Trusted Manufacturer

- Continuous emission monitoring system (CEMS)

- Dust monitoring

- Environmental and process data management

- Environmental dust monitoring

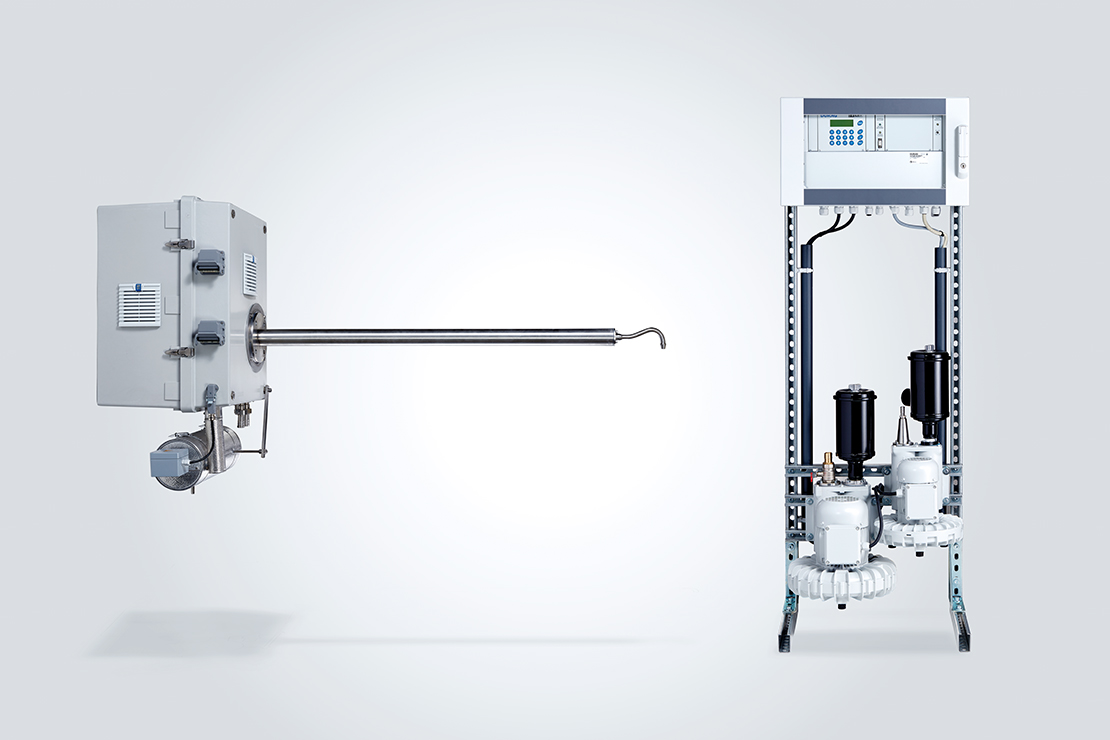

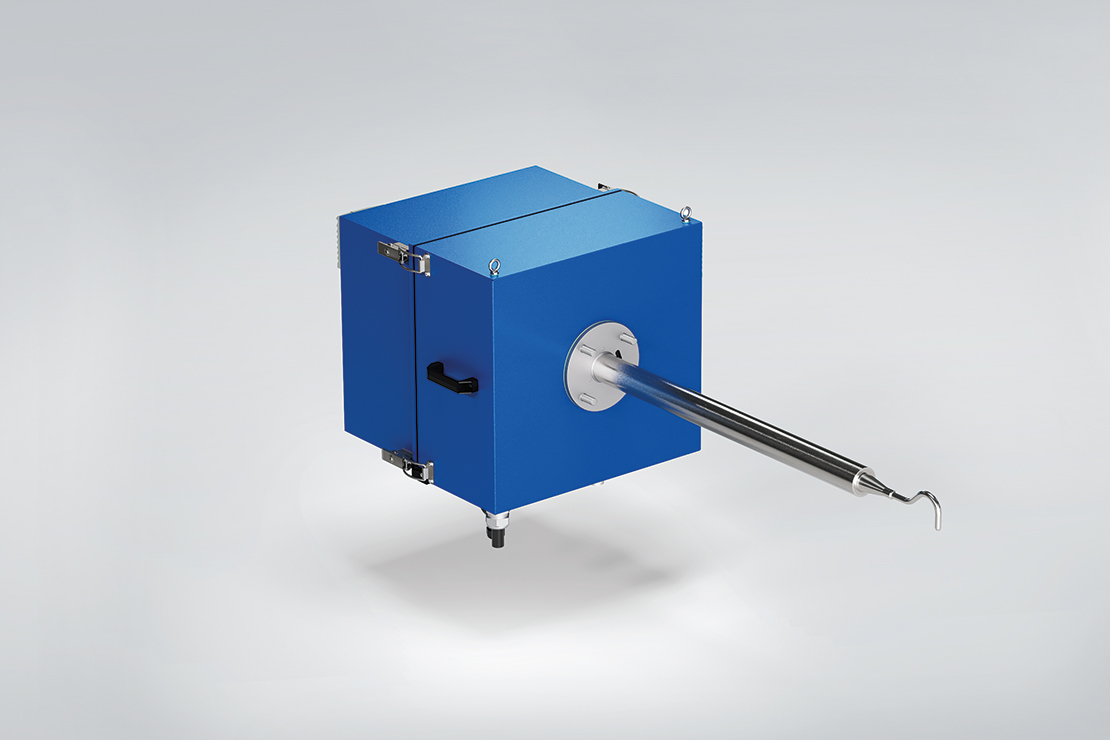

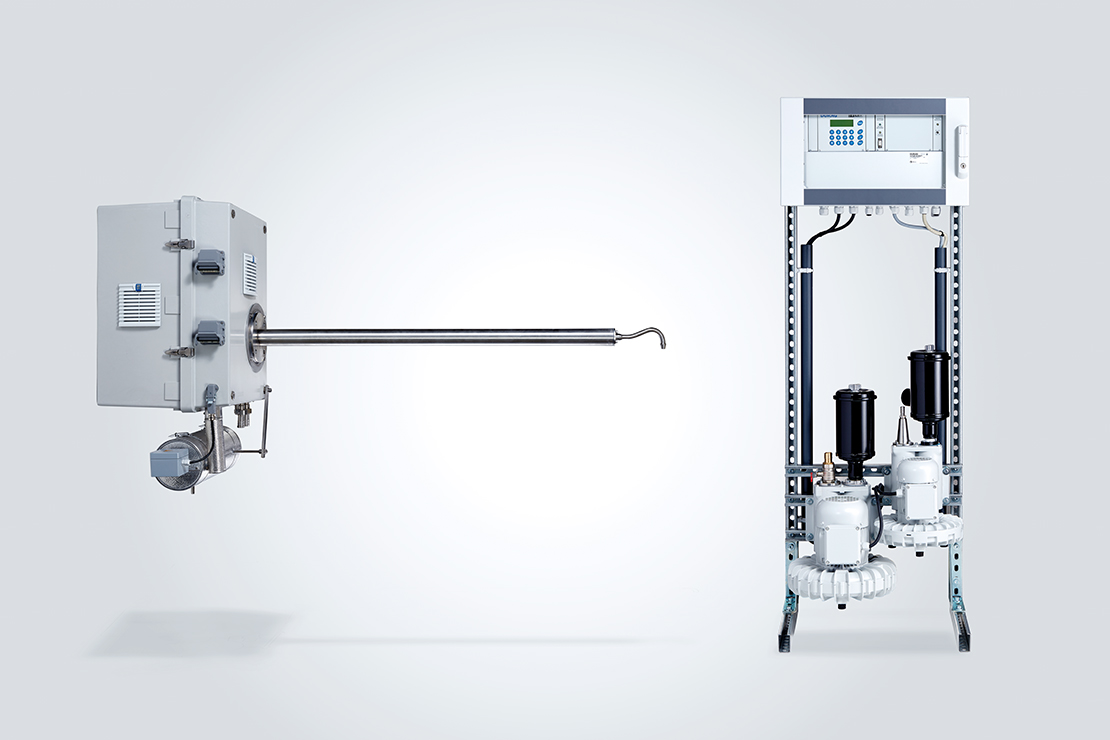

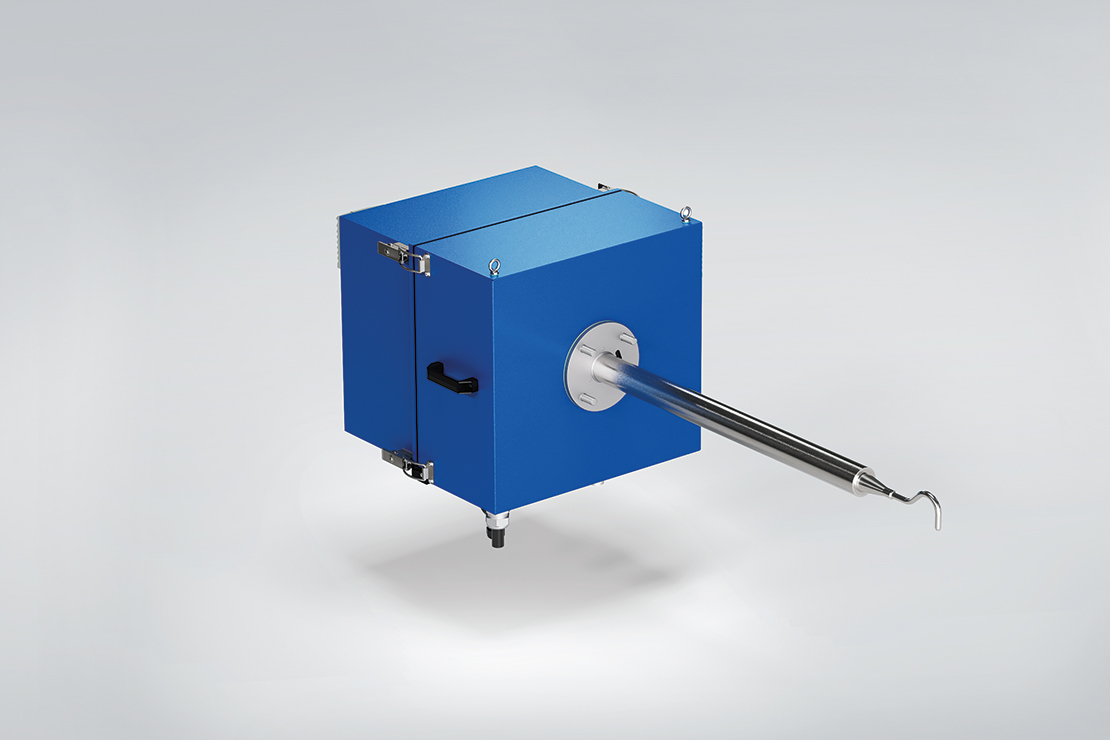

D-R 909

Extractive dust monitor

Extractive continuous dust measurement of small to medium dust concentrations in wet flue and process gases even under difficult plant conditions.

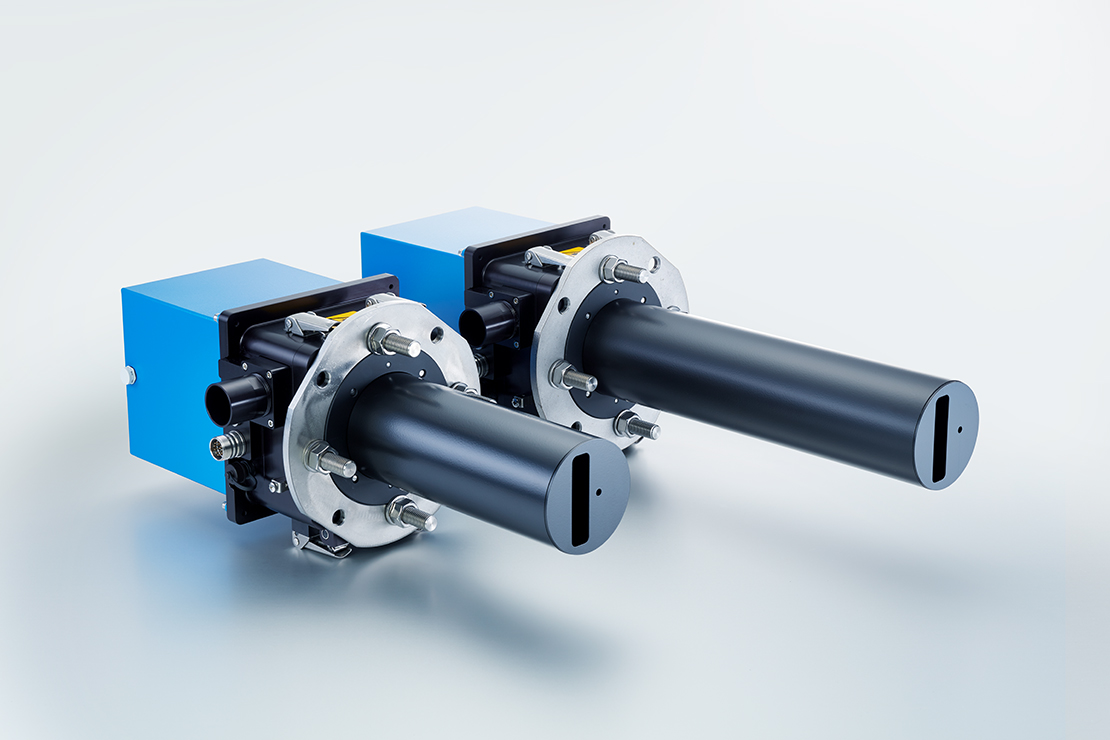

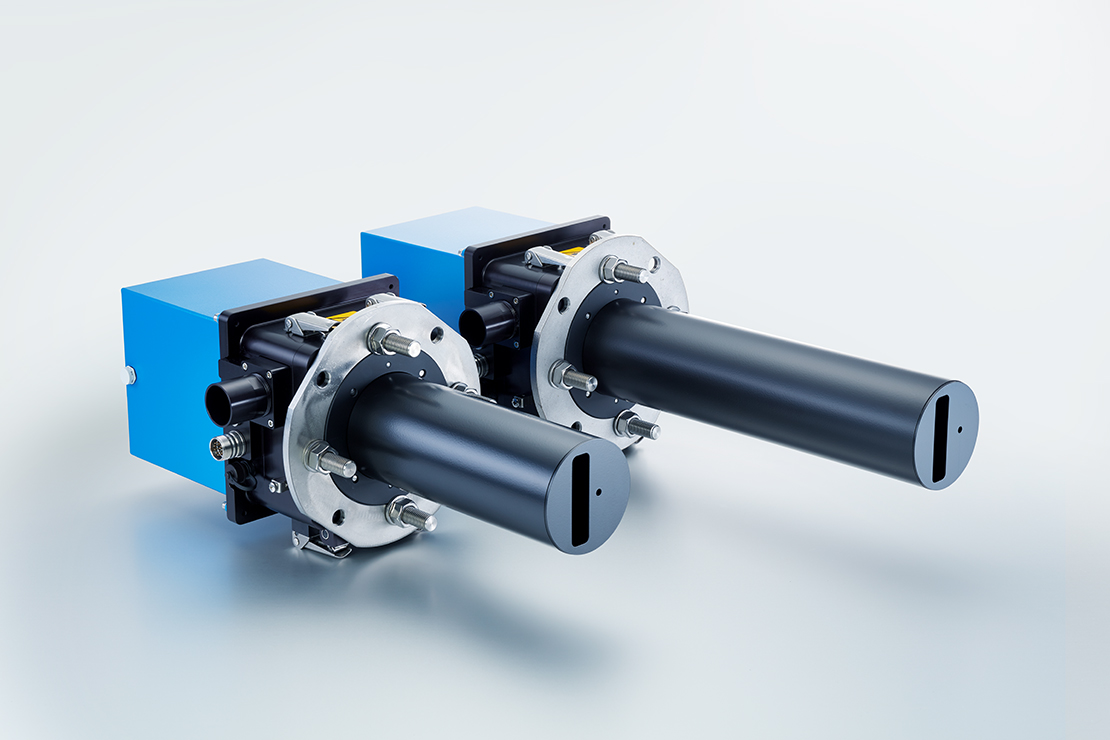

D-R 220

Dust and opacity monitor

The cost-effective solution for continuous, contactless dust and opacity measurement at medium to high concentrations in dry flue and process gases.

D-R 290

Dust and opacity monitor

For continuous, contactless dust and opacity measurement at medium to high concentrations in dry flue and process gases. Also suitable for difficult plant conditions.

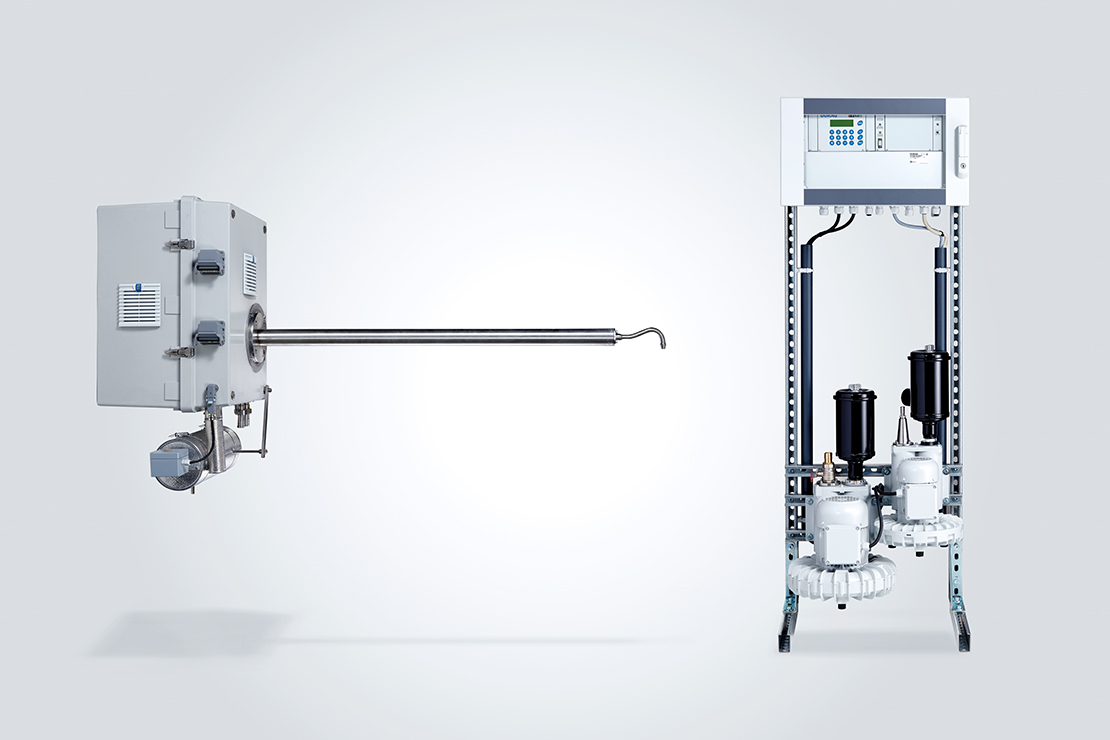

D-R 820 F

Dust monitor

Extractive measurement of wet flue or process gases. For monitoring small to medium dust concentrations.

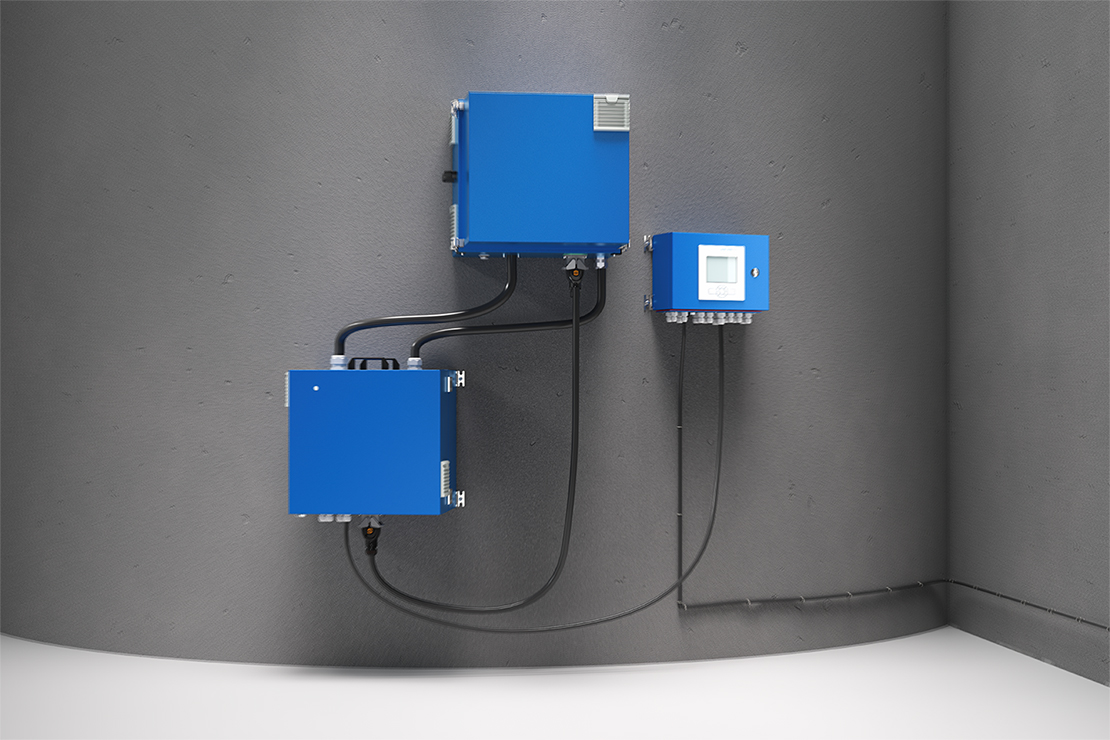

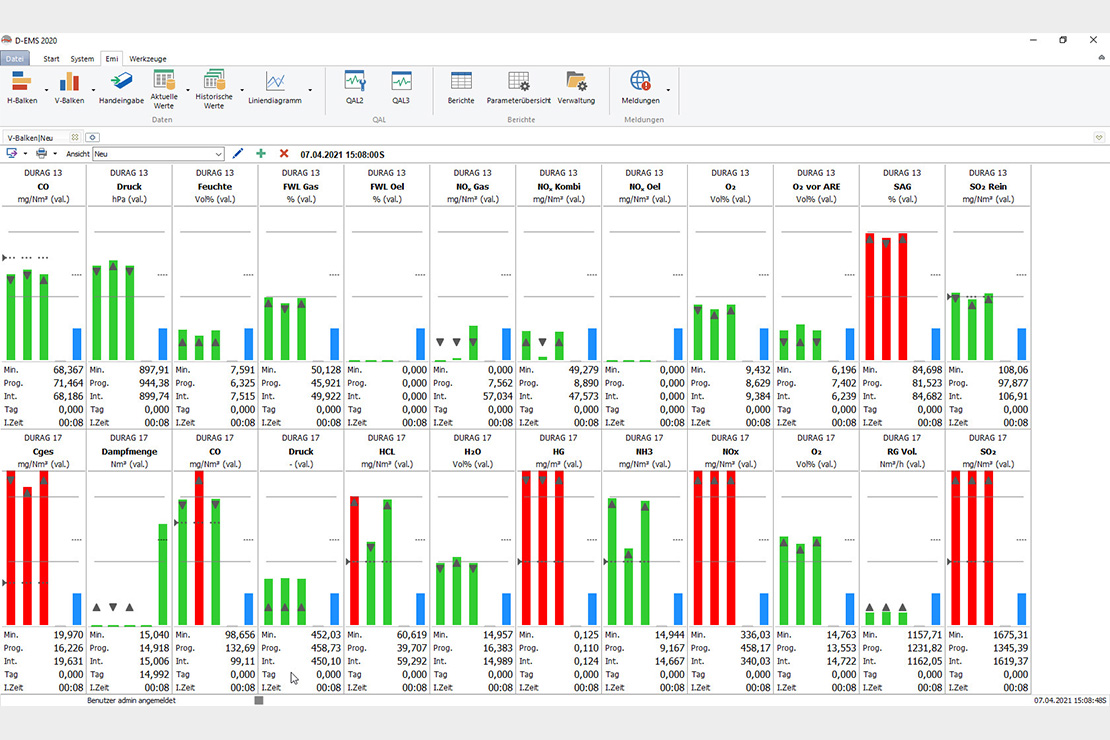

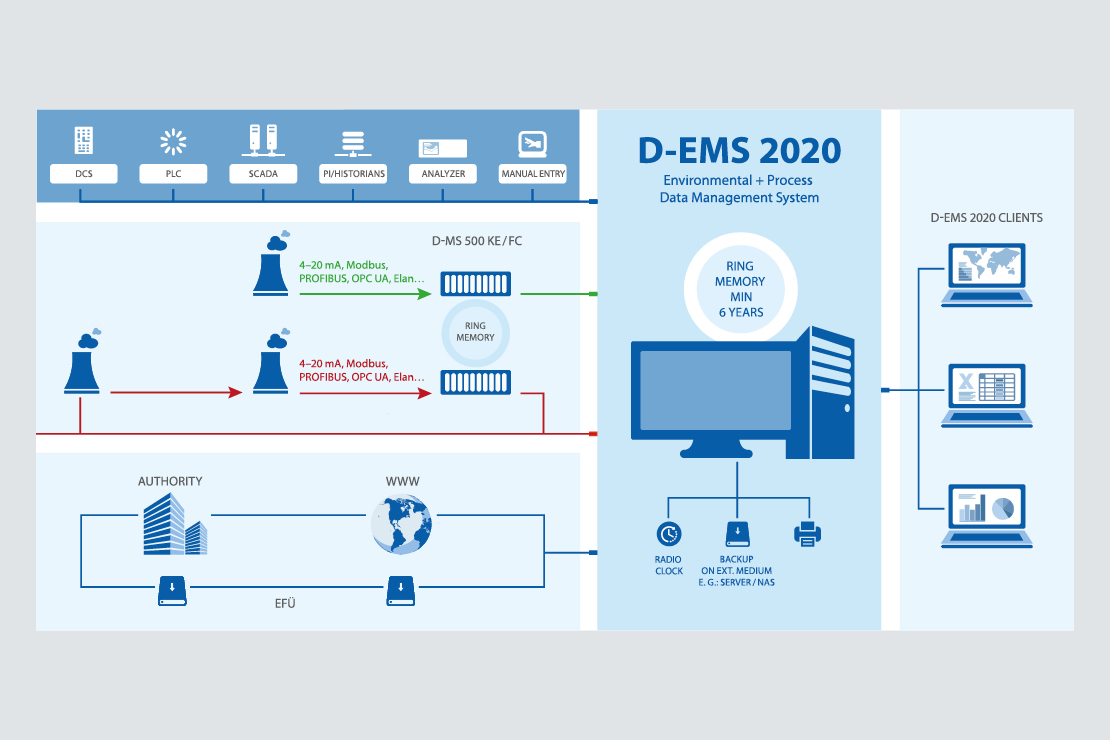

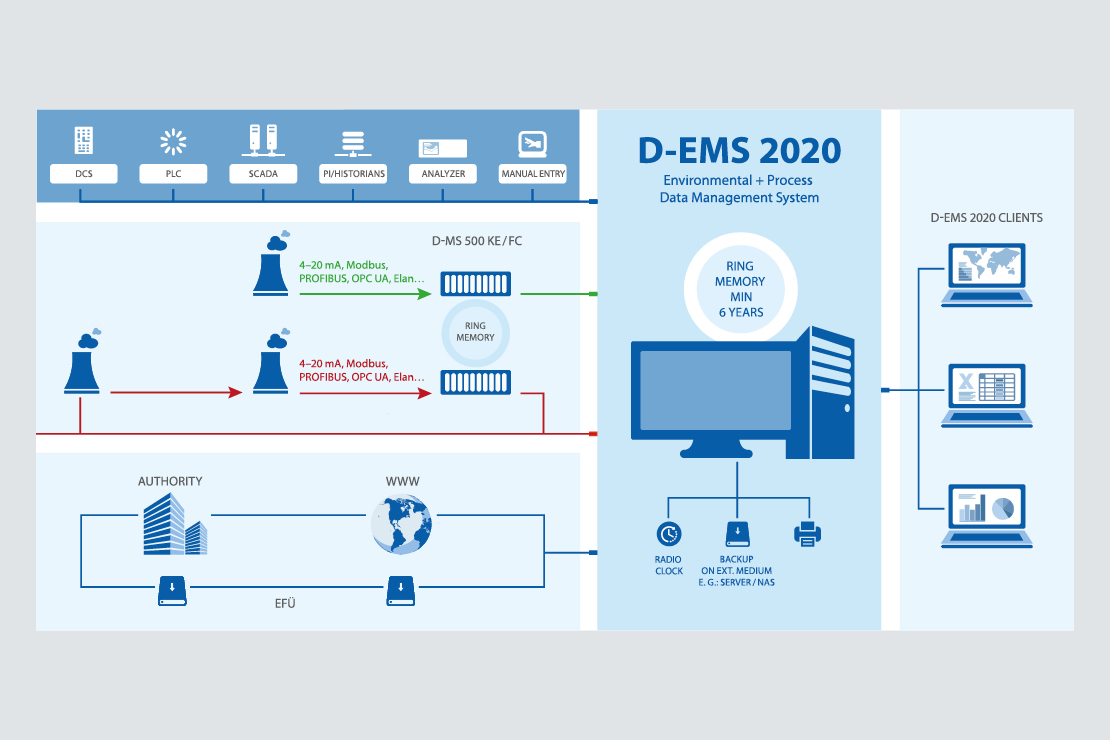

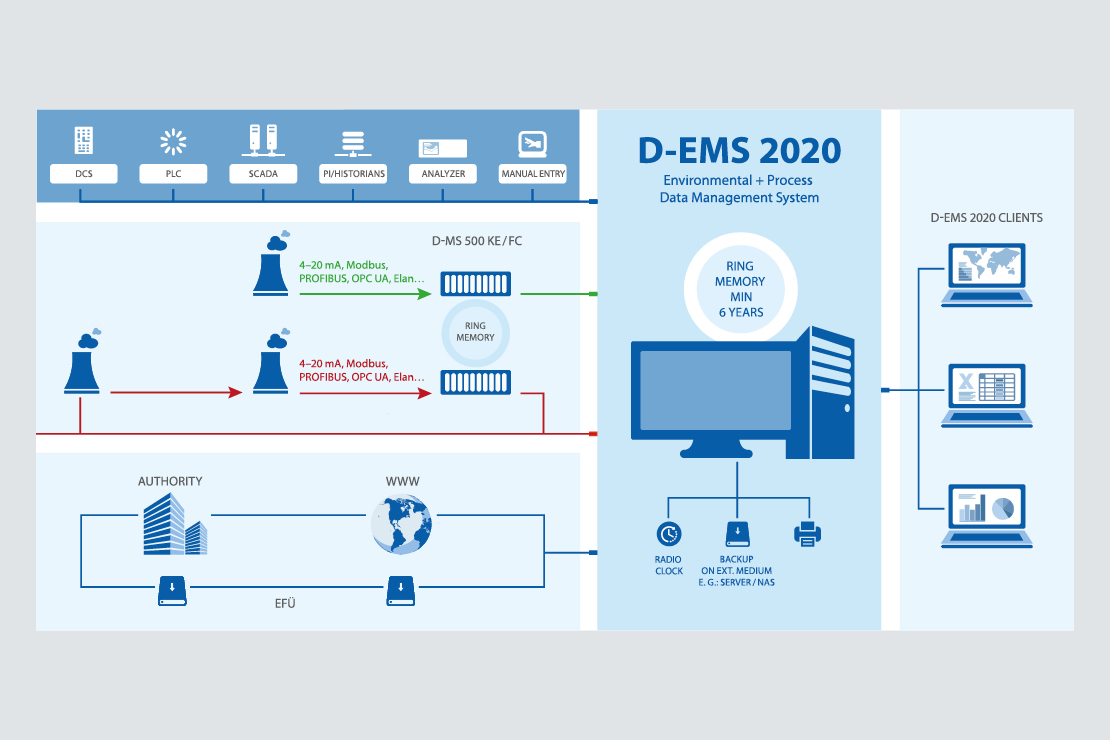

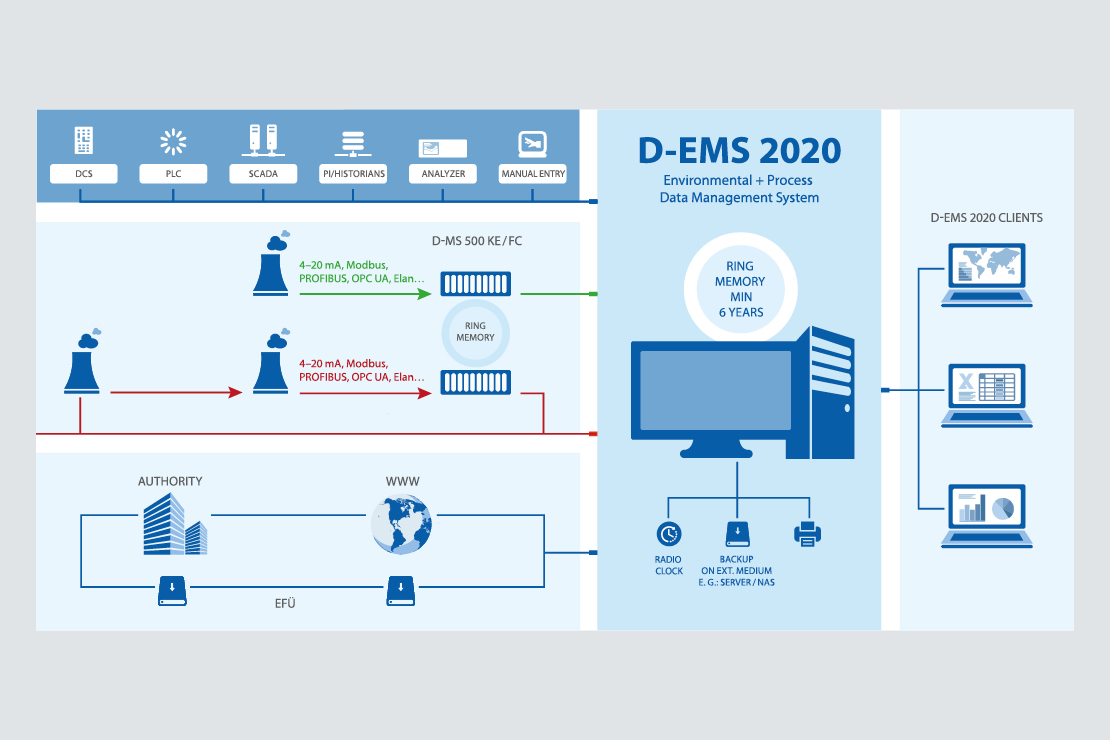

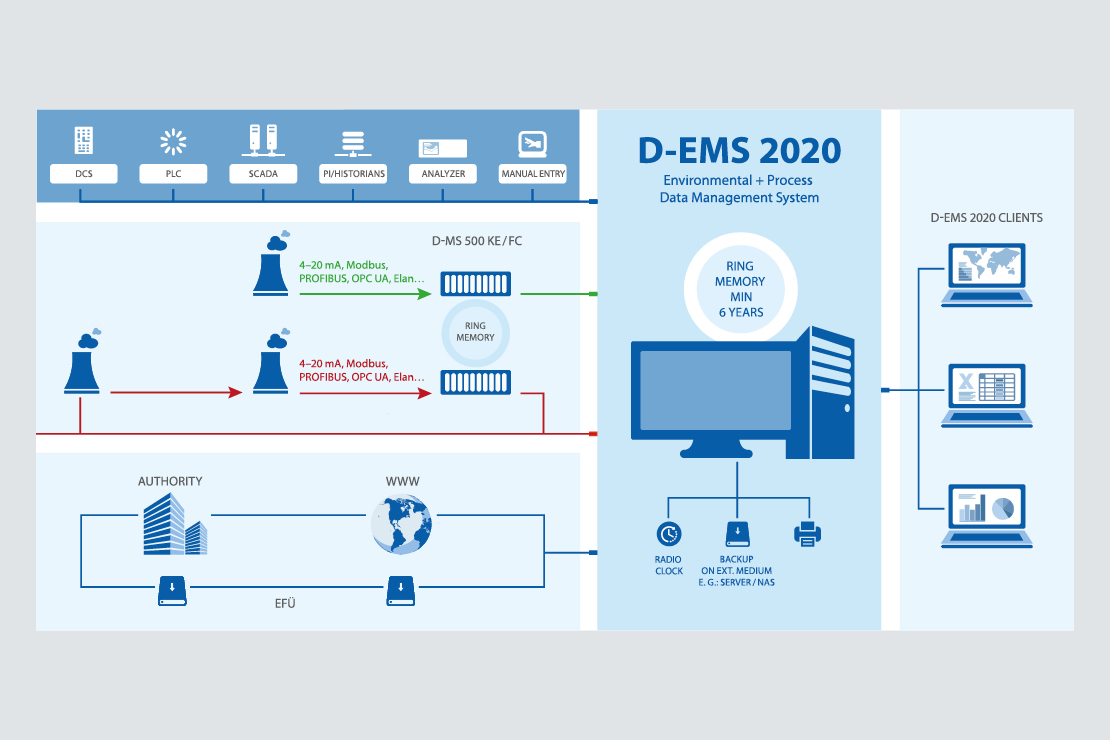

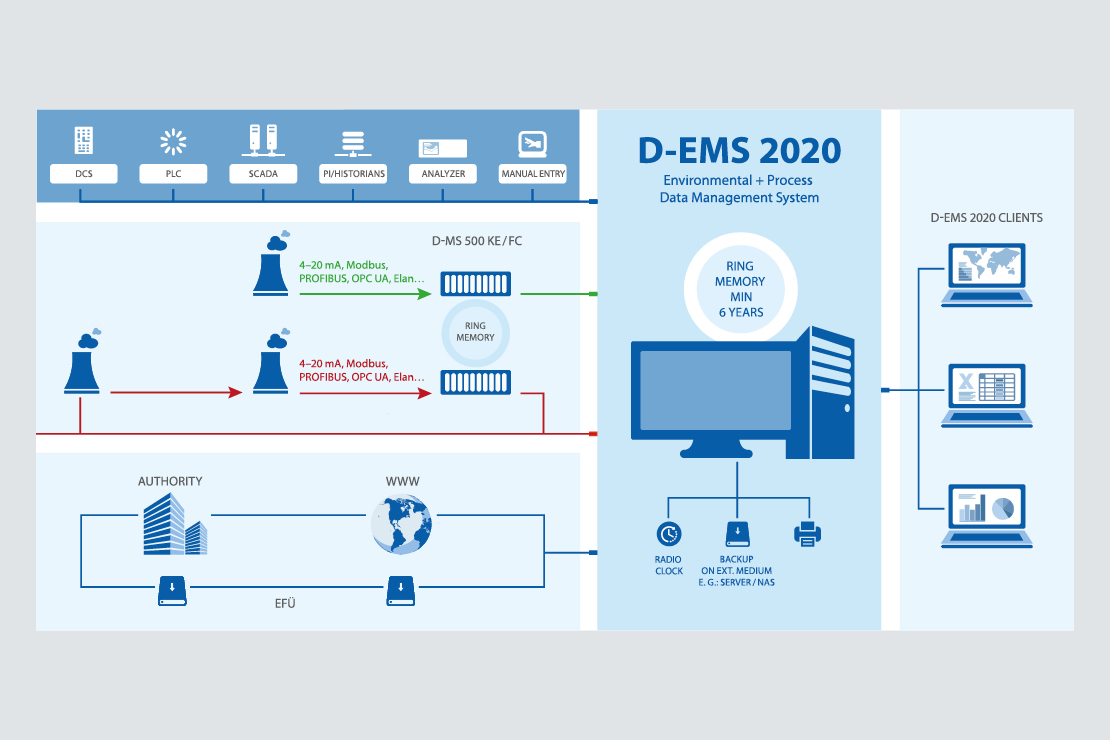

D-EMS 2020

Environmental and process data management system

Data acquisition and handling system (DAHS) for the acquisition, calculation, long-term storage and visualization of data in the most diverse areas. Compliant with European and US EPA-based regulations.

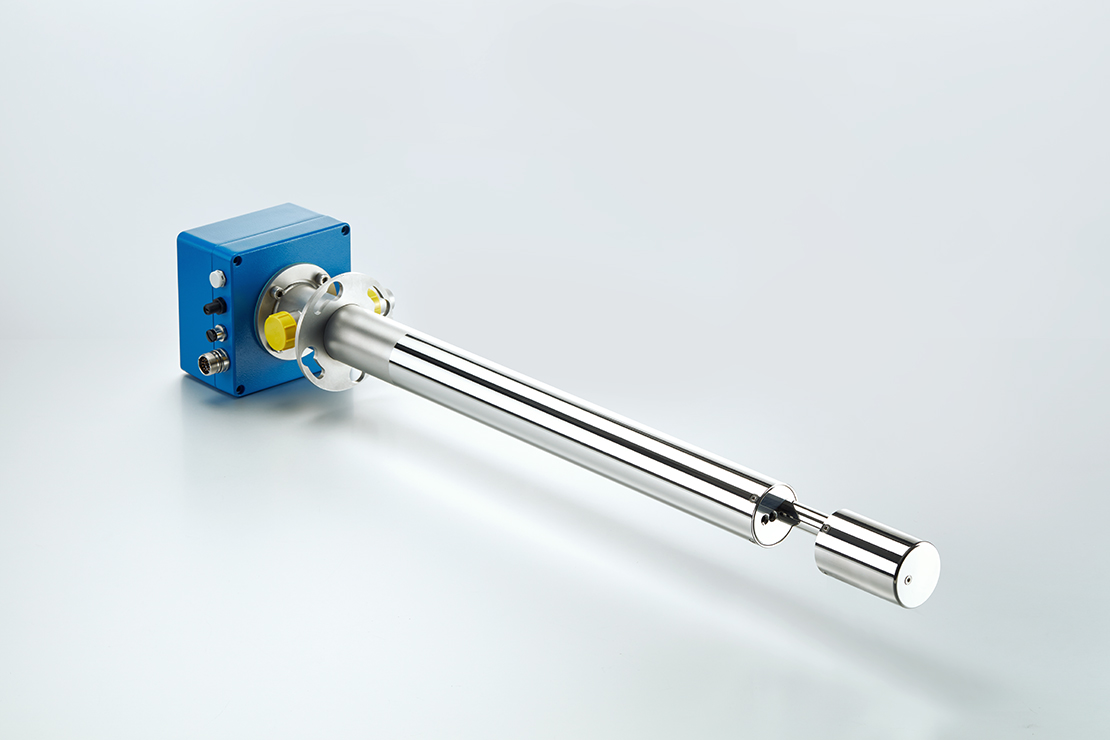

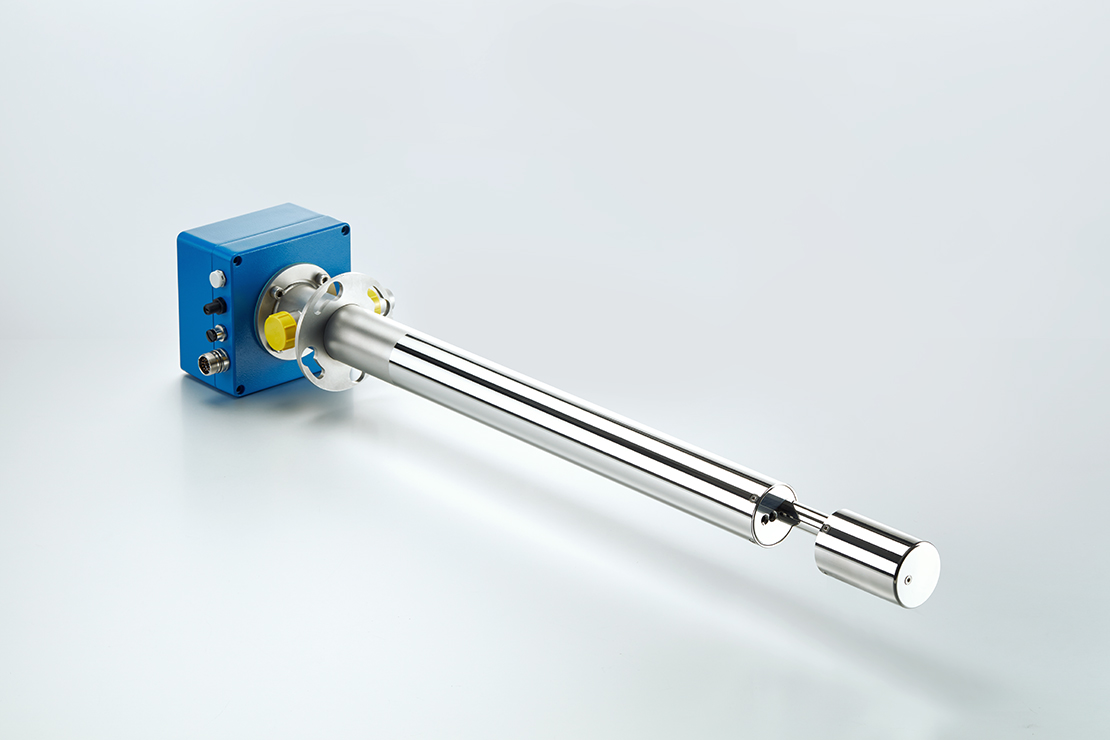

D-R 320

In situ dust monitor

For continuous, contactless measurement of low to medium dust concentrations in dry flue and process gases. Also suitable for corrosive gases and potentially explosive atmospheres.

D-R 808

In situ dust monitor

Certified and approved PM CEMS providing very high quality monitoring of very low to medium particulate concentrations in dry flue gas flows.

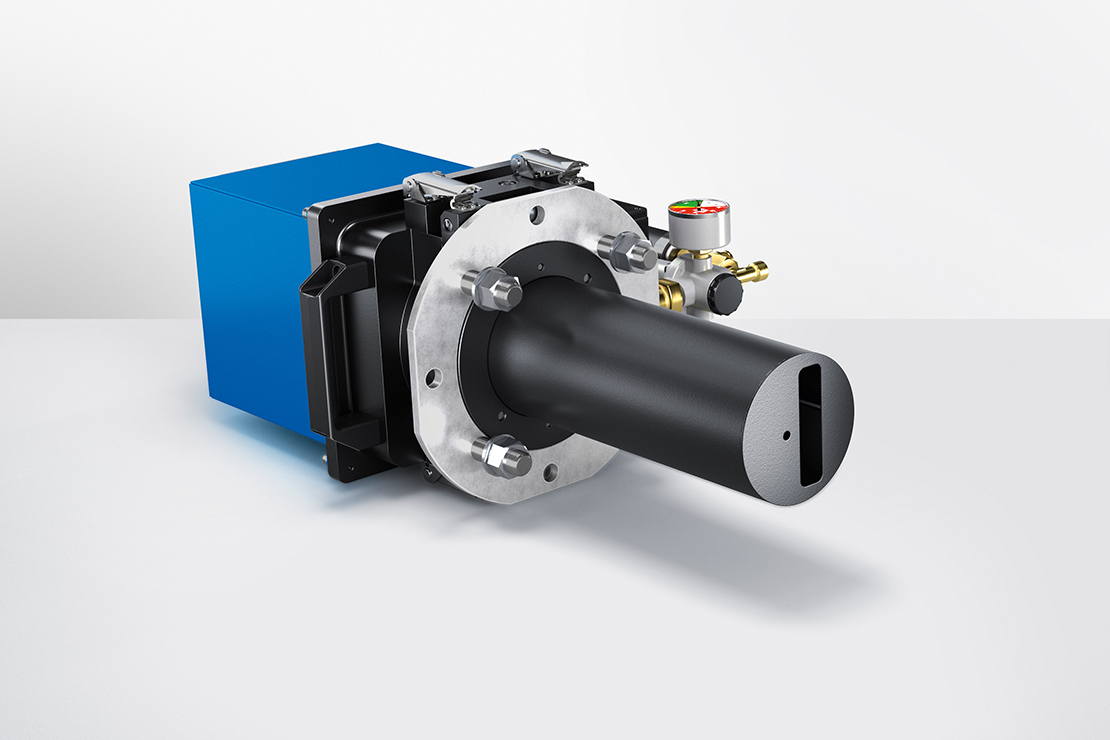

LaserCEM

Multi-gas monitoring system

The LaserCEM® is a turnkey multi-gas stack emissions monitor for environmental compliance, using two patented technologies: OFCEAS® (Optical Feedback Cavity Enhanced Absorption Spectroscopy) and LPS® (Low Pressure Sampling).

HM-1400 TRX 2

Total mercury analyzer

Total mercury analyzer for continuous process and emission monitoring. With option for separate determination of elemental and oxidized mercury species.

D-FL 100

Volume flow measuring system

For continuous volume flow measurement in dry gases. Reliable, even under extreme operating conditions.

D-FL 220

Volume flow measuring system

For continuous, contactless volume flow measurement in dry and humid gases. Reliable, even under demanding operating conditions.

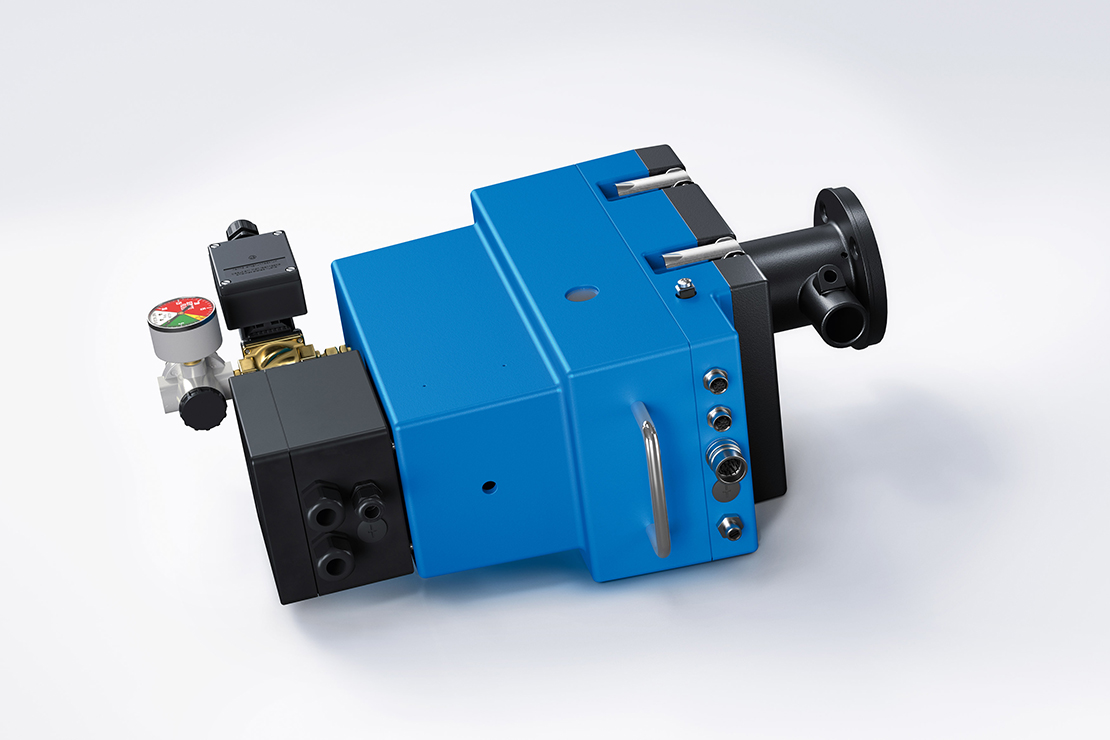

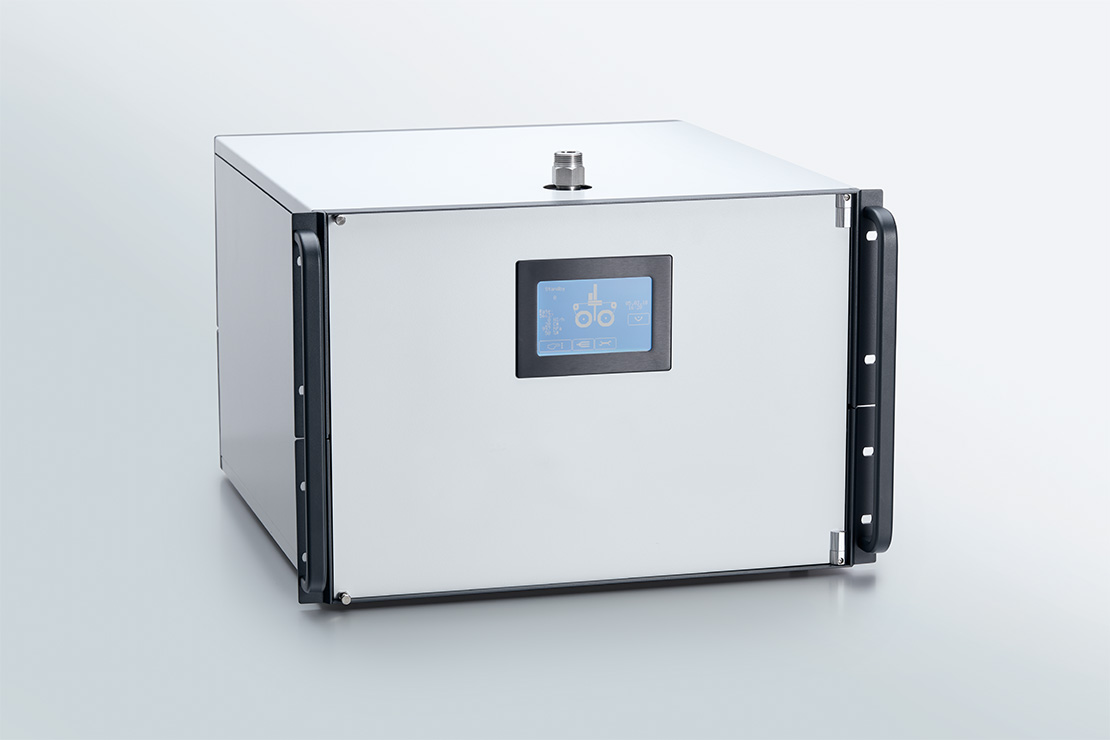

D-R 909

Extractive dust monitor

Extractive continuous dust measurement of small to medium dust concentrations in wet flue and process gases even under difficult plant conditions.

Functionality: Forward scattering

Request A QuoteFeatures

- QAL1-certified in accordance with EN 15267

- Automatic control functions

- Flow-optimized design prevents the deposit of impurities

- Efficient operation due to electronically controlled blowers and heaters

- Modular system of compact units

Benefits

- Suitable for official emission monitoring

- Low service cost for calibration and maintenance

- Low energy cost

- Easy and versatile installation

Applications

- Emission measurement of wet flue gases

- Measurement of wet process gases with small to medium dust concentrations

Technical data

| Parameter | Description |

|---|---|

| Measuring principle | Extraction of sample gas, dilution and heating for evaporation of water droplets, forward scattering, single-sided installation |

| Measuring variable | Scattered light units, calibratable as dust concentration in mg/m³ |

| Measuring range | Minimum 0 … 5 mg/m³; Maximum 0 … 200 mg/m³ |

| Certified measuring ranges | 0 … 7,5 mg/m³; 0 … 15 mg/m³; 0 … 45 mg/m³; 0 … 100 mg/m³ |

| Ambient conditions | Installation location: Indoor or outdoor installation* Temperature: -40 … +60 °C |

| Operating conditions | Temperature: 0 … 160 °C (Higher temperature values on request) Relative humidity: 0 … 100% and maximum 70 g/m³ water as aerosol Relative pressure: -50 … +50 hPa** |

| Inner duct diameter | Minimum: 0.2 m |

| Interface | Analog output: 1x 4 … 20 mA, maximum 500 Ω, potential-free Analog input: 1x 4 … 20 mA, maximum 250 Ω, potential-free Digital output: 2x NC/NO, maximum 60 V_, 30 V~, 0.5 A Modbus RS 485 RTU USB |

| Operation and display | Status LED |

| Software | D-ESI 100*** |

| Optional | Control Unit D-ISC 100 |

| Control functions | Automatic zero point and reference point measurement, automatic contamination measurement and compensation |

| Light source | Laser, class 2 in accordance with EN 60825-1, < 1 mW at 650 nm |

* Weather protection required for outdoor installation

** Depending on flue gas velocity and operating mode

*** Enables remote access via web interface, requires PC with Windows operating system

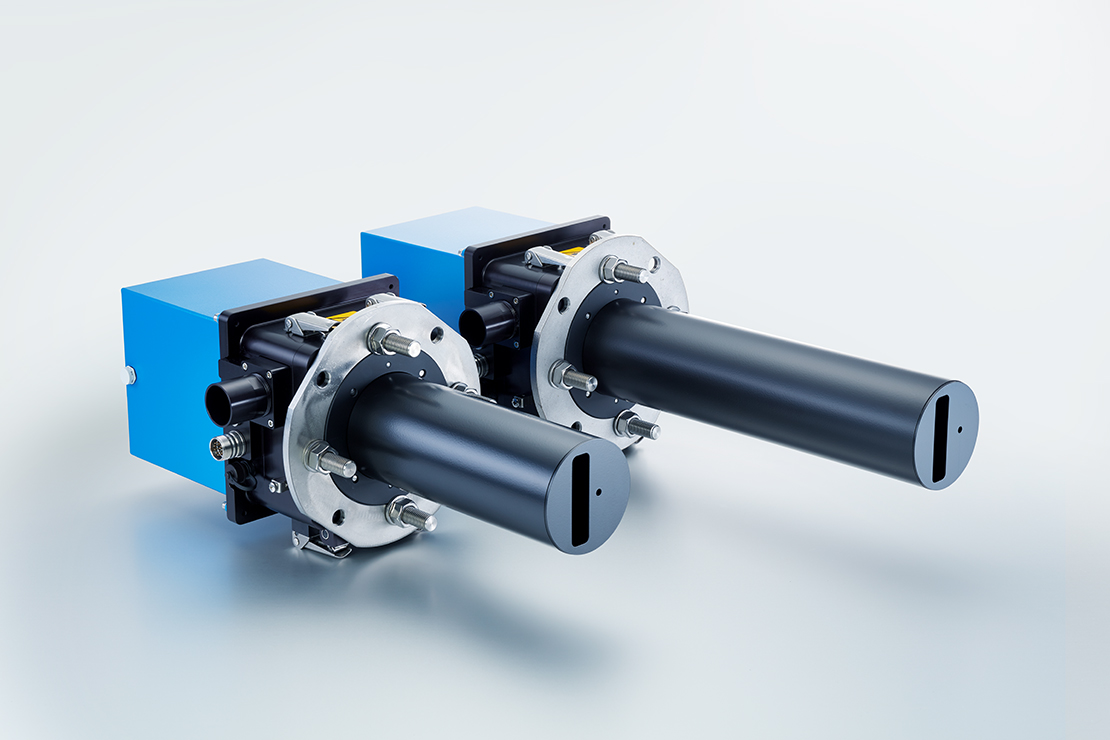

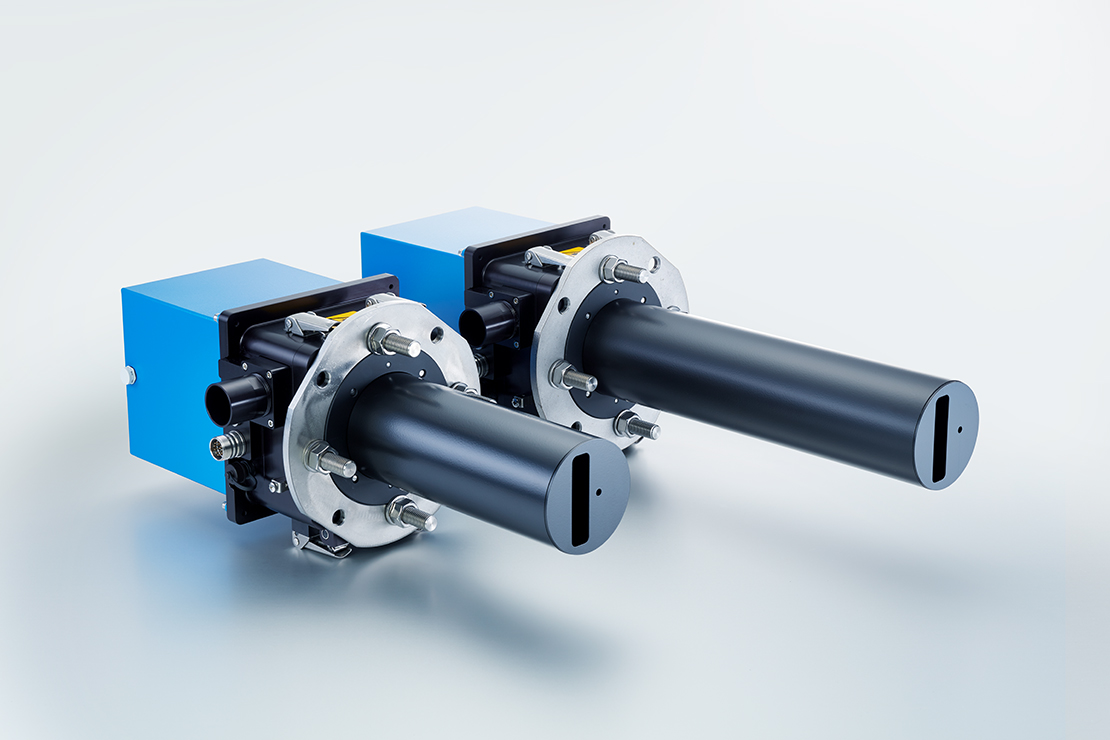

D-R 220

Dust and opacity monitor

The cost-effective solution for continuous, contactless dust and opacity measurement at medium to high concentrations in dry flue and process gases.

Functionality: Transmission

Request A QuoteFeatures

- Continuous dust measurement

- Contactless measurement

- Automatic check functions

- High-quality corrosion-free plastic housing and a wide ambient temperature range

Benefits

- Easy installation for opacity monitoring and reliable emission monitoring

- Reliable measurement of medium to large dust concentrations

- Space-saving and easy installation

- Transmission measuring principle opens up a wide range of applications

- Also for use under extreme sample gas conditions

Applications

- Emission measurement of dry flue gases at the stack

- Measurement of dry flue gases in the process

- Corrosive flue gases, challenging gas matrix

- Measurement of dry process gases

Technical Data

| Parameter | Description |

|---|---|

| Measuring principle | Transmission, contactless and in-situ measurement |

| Measuring variable | Extinction, opacity, calibratable as dust concentration in mg/m³ |

| Measuring range | Opacity: 0 … 100% Extinction: 0 … 1.6 Dust concentration: 0 … 5,000 mg/m³ |

| Certified measuring range | n/a |

| Ambient conditions | Installation location: Indoor or outdoor installation** Temperature: -20 … +50 °C |

| Operating conditions | In duct: Temperature: Maximum 200 °C, optional: 500 °C Relative humidity: 0 … 95%, non-condensing Relative pressure: -50 … +10 hPa (standard) -50 … +50 hPa (optional) |

| Inner duct diameter | 0.4 … 10 m |

| Interface* | Analogue output: 1x 4 … 20 mA, maximum 400 Ohm, potential-free (various parameters adjustable) Digital output: 2x NC/NO, maximum 60 VDC, 30 VAC, 0.5 A (various parameters adjustable) RS 485 Modbus RTU, USB |

| Status display | LED |

| Operation and display | Software D-ESI 100*** or Operating unit D‑ISC 100 |

| Check functions | Automatic zero point and reference point measurement, manual contamination and linearity measurement (optional) |

| Light source | LED |

* Additional interfaces with D‑ISC 100 operating unit

** Weather protection cover required for outdoor installation

*** Enables remote access via web interface, PC with Windows operating system required

System components

| Component | Description |

|---|---|

| Dust monitor D-R 220 | Measuring head and reflector |

| Software D-ESI* | Measurement software for control and monitoring* |

| Terminal Box with purge air unit | D-TB 200 |

| Terminal Box without purge air unit | D-TB 100* |

| Operating and purge air unit | D-ISC 100 P |

* Enables remote access via web interface, PC with Windows operating system required

USP

- High quality at a low price

Accessories

Mandatory

- D-TB x00

- D‐ESI 100

- D-BL

Recommended

- D-ISC 100 xx2

D-R 290

Dust and opacity monitor

For continuous, contactless dust and opacity measurement at medium to high concentrations in dry flue and process gases. Also suitable for difficult plant conditions. Exceeds EPA and ASTM standards.

Functionality: Transmission

Request A QuoteFeatures

- Continuous dust measurement

- Smallest certified measuring range 0 … 15 mg/m³

- Automatic measurement and correction of contamination

- Automatic check functions

- Contactless measurement

- Maintenance and linearity check without disassembly

- Exceeds EPA and ASTM standards The D-R 290 was developed to comply with 40CFR60, App. B, PS-1 and ASTM D6216-20 Annex A1 “Standard Practice for Opacity Manufactures to Certify Conformance with Design and Performance Specifications."

Benefits

- Suitable for official emission monitoring

- Reliable measurement of medium to large dust concentrations

- Space-saving and easy installation

- Long life time and high availability under extreme plant conditions

Applications

- Emission measurement of dry flue gases at the stack

- Temperatures up to 1,000 °C

- Corrosive flue gases, plants with complex gas matrix

- Measurement of dry process gases

Technical Data

| Property | Details |

|---|---|

| Measuring principle | Transmission, contactless and in-situ measurement |

| Measuring variable | Extinction, opacity, calibratable as dust concentration in mg/m³ |

| Measuring range |

Opacity: Minimum 0 … 20%, maximum 0 … 100% Extinction: Minimum 0 … 0.1, maximum 0 … 2.0 Dust concentration: Minimum 0 … 80 mg/m³, maximum 0 … 4,000 mg/m³ |

| Certified measuring range | 0 … 15 mg/m³ |

| Ambient conditions |

Installation location: Indoor or outdoor installation Temperature: -40 … +60 °C (Standard) -30 … +60 °C (ATEX) -20 … +60 °C (IECEx) |

| Operating conditions |

In duct: Temperature: Maximum 250 °C, optional: 1,000 °C Relative humidity: 0 … 95%, non-condensing Relative pressure: -50 … +20 hPa, -50 … 0 hPa (ATEX/IECEx) |

| Inner duct diameter | 0.5 … 18 m |

| Interface |

Analogue output: 1x 4 … 20 mA, maximum 400 Ohm, potential-free (various parameters adjustable) Digital output: 2x NC/NO, maximum 60 VDC, 30 VAC, 0.5 A (various parameters adjustable) RS 485 Modbus RTU, USB Status display: LED |

| Operation and display | Software D-ESI 100 or Operating unit D-ISC 100 |

| Check functions | Automatic zero point and reference point measurement, automatic contamination measurement and compensation |

| Light source | LED, 450 … 680 nm |

* Additional interfaces with D‑ISC 100 operating unit

** Weather protection cover required for outdoor installation

*** Measuring section > 1 m

Explosion protection

| Certification | Details |

|---|---|

| ATEX |

II 2G Ex pxb IIC T4 Gb II 3G Ex pzc IIC T4 Gc II 3D Ex pD IIIC T100°C Dc |

| IECEx | Ex pzc IIC T4 Gc |

System components

| Component | Description |

|---|---|

| Dust Monitor | D-R 290 (measuring head and reflector) |

| Purge Air Unit(s) | D-BL |

| Software | D-ESI* and Terminal Box without purge air unit |

| Terminal Box | D-TB 100** or Operating unit D‑ISC 100 |

* Enables remote access via web interface, PC with Windows operating system required

** External purge air supply required

D-R 820 F

Dust monitor

Extractive measurement of wet flue or process gases. For monitoring small to medium dust concentrations.

Functionality: Forward scattering

Request A QuoteFeatures

- Dilution of the sample

- Hyperkinetic gas extraction

- Single-sided installation on stack

- Automatic zero point and reference point check

- Automatic measurement of contamination and correction of measured values

- Local control panel and LC display

Benefits

- Suitable for plants with variable gas velocity

- Long life time due to stable laser light source

- Easy commissioning, adjustment and maintenance without PC

Applications

- Emission measurement of wet flue gases

- Measurement of wet process gases with small to medium concentrations

Technical Data

| Specification | Details |

|---|---|

| Measuring Principle | Extraction of sample gas, dilution and heating for evaporation of H2O, forward scattering, single-sided installation |

| Measuring Variable | Stray light units, calibratable as dust concentration in mg/m³ |

| Measuring Range | Minimum 0 … 15 mg/m³, Maximum 0 … 200 mg/m³ |

| Certified Measuring Range | 0 … 15 mg/m³ |

| Ambient Conditions | Installation location: Indoor or outdoor installation Temperature: -20 … +50 °C |

| Operating Conditions | In duct: Temperature: -25 … 220 °C Relative humidity: > 95 %, maximum 30 g/m³ H2O as aerosol Relative pressure: -30 … +2 hPa |

| Inner Duct Diameter | Minimum 0.4 m |

| Interface | Analogue output: 4x 4 … 20 mA, maximum 1,000 Ohm, potential-free Digital output: 4x NC/NO, maximum 35 VDC, 0.4 A |

| Operation and Display | Supply and display unit on the measuring device |

| Check Functions | Automatic zero point and reference point measurement, automatic contamination measurement and compensation |

| Light Source | Laser diode, red, 650 nm |

* Weather protection cover required for outdoor installation

System components

(Bullet) Dust monitor D-R 820 F (including blower unit and supply and display unit)

USP

- Suitable for extreme plant conditions

- Low lifecycle costs

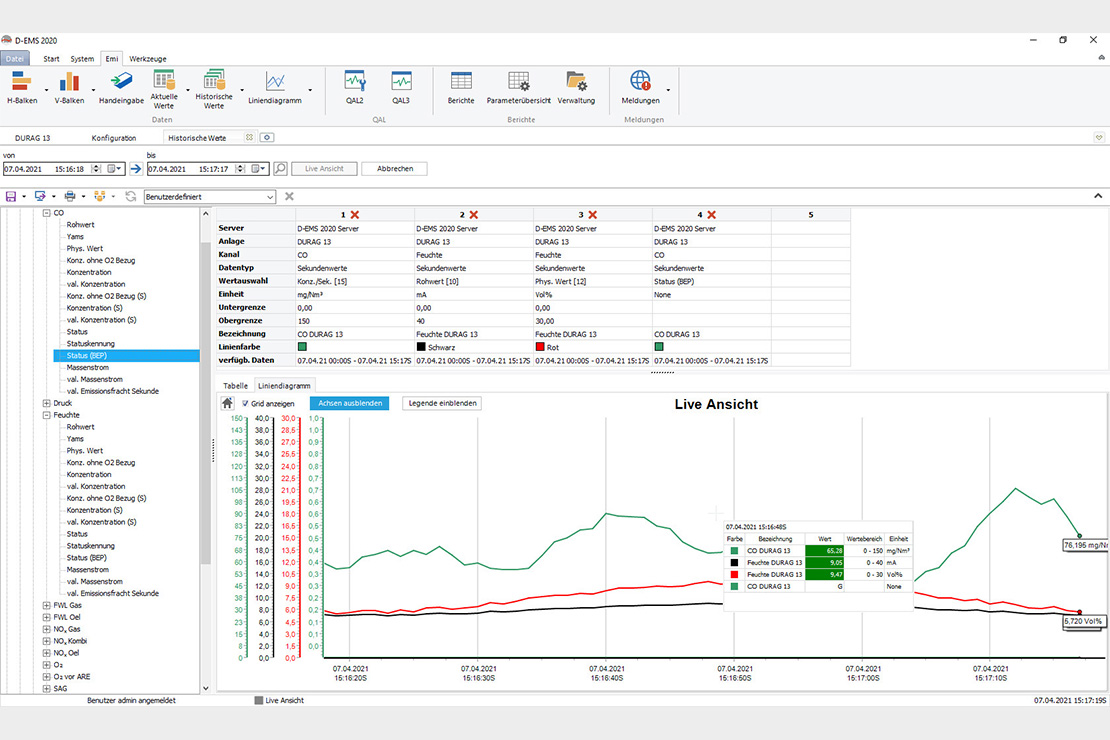

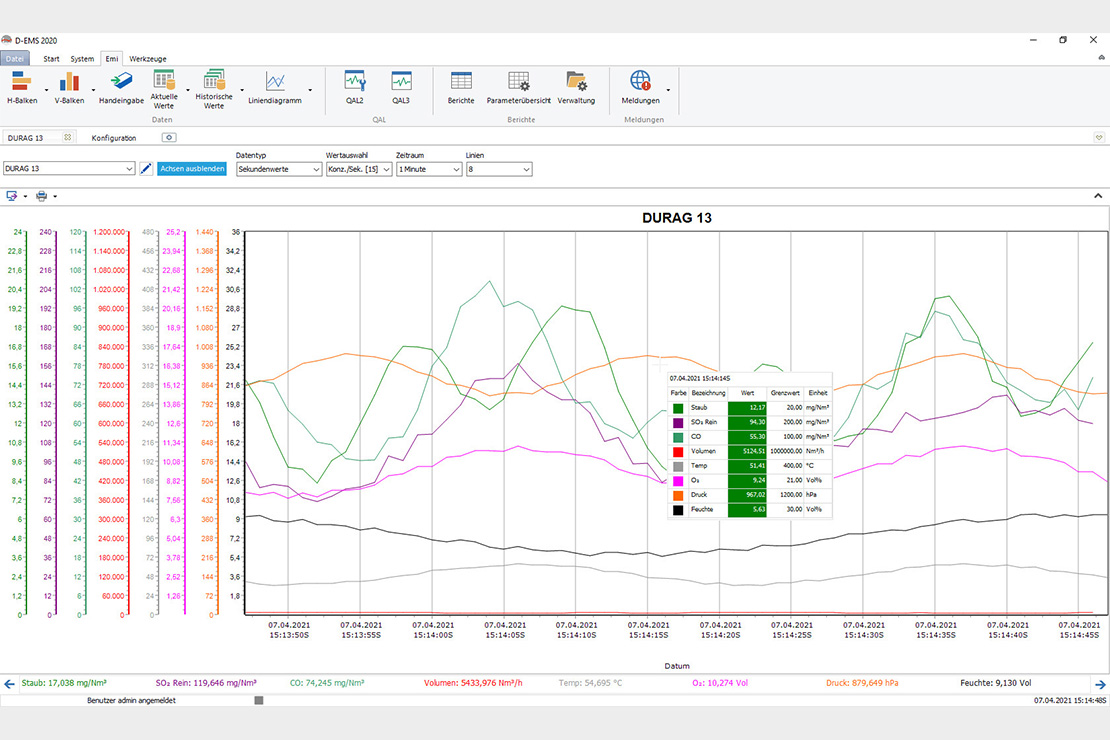

D-EMS 2020

Environmental and process data management system

Data acquisition and handling system (DAHS) for the acquisition, calculation, long-term storage and visualization of data in the most diverse areas. Compliant with European and US EPA-based regulations.

The D-EMS 2020 system is an environmental and process data management system which meets today’s legal requirements and is conceptually prepared for future guidelines. The system enables the acquisition, calculation, long-term storage and visualization of environmental data and process data in the most diverse areas.

Functionality: The system is modular in structure and makes it possible to implement a wide range of user-specific solutions. All calculations, storage and display take place within the D-EMS 2020 server. Additional workstations or clients can be connected via network with diverse functions.

Functionality: Forward scattering

Request A QuoteFeatures

- New: Since December 2024, tested according to EN 17255

- Complies with European and US EPA based regulations

- Analog and digital data acquisition with long-term data storage in accordance with legal requirements

- Provision of data to customer systems via analog and digital interface

- Presentation of current, historical or forecast measurement data as bar or line chart and optionally in customer-specific design

- Standalone and client-server architecture, installation options to meet the various customer requirements

- Role-based user management, including LDAP(S)

- Additional modules such as GHG, QAL3, automatic backup, and many more

Certifications

- EN 15267 (QAL1)

- MCERTS

Conformities Germany

- TA Luft

- 1. BImSchV

- 2. BImSchV

- 13. BImSchV

- 17. BImSchV

- 27. BImSchV

- 30. BImSchV, 31. BImSchV

- BEP 2017

- Statuskennung und Klassierung (SKK) 2019

- DIN EN 14181

- MVO (DEHSt)

- VDI 4201

Conformities EU

- 2010/75/EU (IED)

- (EU) 2015/2193 (MCP)

- EN 14181

- EN 17255

- And other national requirements

Conformities US

- US EPA 40 CFR Part 60

- US EPA 40 CFR Part 63

- US EPA 40 CFR Part 75

- And other US EPA-based evaluations

Benefits

- Scalable and modular system for all plant sizes and types

- Fully-featured modern system design

- Intuitive and easy-to-use interface

- Flexible configuration to meet the various customer requirements

- Powerful reporting with multiple customization options and e-mail notification

- Complies with European and US EPA based regulations

Technical data

| Specification | Details |

|---|---|

| Data Acquisition |

Per server up to 1024 analog inputs Per server up to 1024 analog outputs Per server up to 2048 analog inputs Per server up to 2048 analog outputs Data acquisition can be carried out either directly or via data loggers in the D-MS 500 FC family to the server. |

| Interfaces |

4-20mA Modbus RTU / TCP Profibus DP Profibus Master (VDI 4201) Profinet Elan OPC UA Mode 4 Ethernet IP And others |

| Data Export | PDF, XLS, XML, CSV files |

| Data Security |

Data buffer in the D-MS 500 FC data logger family with internal ring memory of up to 128 days Encrypted data communication between server and data loggers Encrypted and password protected SQL database Role-based user management, including LDAP(S) External data storage and backup (file server, NAS, etc.) Alarm notification on failure of a storage medium |

| Internet/Intranet Connection |

Automatic data transfer to any web server on the Internet for visualization via HTML Daily data control |

| Visualization |

Reporting (daily, monthly, quarterly, yearly, etc.) Bar and line charts with current and historical data Alarm and event management with comment functionality and e-mail notification |

D-R 320

In situ dust monitor

For continuous, contactless measurement of low to medium dust concentrations in dry flue and process gases. Also suitable for corrosive gases and potentially explosive atmospheres.

Technology: Backward scattering

Request A QuoteFeatures

- Continuous dust measurement

- Smallest certified measuring range 0 … 7.5 mg/m³

- Single-sided installation without optical alignment

- Automatic check functions

- Continuous, integrated purge air monitoring and control

- Maintenance and linearity check without disassembly

- Contactless measurement

Benefits

- Suitable for official emission monitoring

- Reliable measurement of small dust concentrations

- Space-saving and easy installation

- Long life time and high availability under extreme plant conditions

- Low maintenance

Application

- Emission measurement of dry flue gases at the stack

- Temperatures up to 600 °C

- Corrosive flue gases, plants with complex gas matrix

- Measurement of dry process gases with small concentrations

Technical data

| Parameter | Details |

|---|---|

| Measuring Principle | Backward scattering, single-sided installation, contactless and in-situ measurement |

| Measuring Variable | Stray light units, calibratable as dust concentration in mg/m³ |

| Measuring Range |

Minimum: 0 … 5 mg/m³ Maximum: 0 … 200 mg/m³ |

| Certified Measuring Range | 0 … 7.5 mg/m³ |

| Ambient Conditions |

Installation location: Indoor or outdoor installation** Temperature: -40 … +60 °C -30 … +60 °C (ATEX) -20 … +60 °C (IECEx) |

| Operating Conditions |

In duct: Temperature: Maximum 600 °C Relative humidity: 0 … 95%, non-condensing Relative pressure: -50 … +50 hPa -50 … 0 hPa (ATEX/IECEx) |

| Dimensions |

Inner duct diameter: Minimum 0.7 m Wall thickness: Maximum 0.56 m |

| Interface* |

Analogue output: 1x 4 … 20 mA, max 400 Ohm, potential-free (adjustable) Digital output: 2x NC/NO, max 60 VDC, 30 VAC, 0.5 A (adjustable) RS 485 Modbus RTU, USB Status display: LED |

| Operation and Display |

Software D-ESI 100*** or Operating unit D-ISC 100 |

| Check Functions |

Automatic zero and reference point measurement Automatic contamination measurement and compensation Integrated purge air monitoring and control |

| Protective Functions | Integrated fail-safe shutter (optional) |

| Light Source | Laser, class II, < 1 mW at 650 nm |

* Additional interfaces with D-ISC 100 operating unit

** Weather protection cover required for outdoor installation

*** Enables remote access via web interface, PC with Windows operating system required

Explosion protection

| Standard | Certification |

|---|---|

| ATEX |

II 2G Ex px op is IIC T4 Gb II 3G Ex pz op is IIC T4 Gc II 3D Ex pD III T70 °C Dc |

| IECEx | Ex pzc IIC T4 Gc |

System components

| Component | Description |

|---|---|

| Main Unit | Dust monitor D-R 320 |

| Software | D-ESI* |

| Connection Options |

Terminal Box with purge air unit D-TB 200 or Terminal Box without purge air unit D-TB 100** or Operating and purge air unit D-ISC 100 P |

* Enables remote access via web interface, PC with Windows operating system required

** External purge air supply required

USP

- Patented design, without alignment of optical components after installation

Accessories

Mandatory

- D-TB x00

- D‐ESI 100

Recommended

- D-ISC 100 xx2

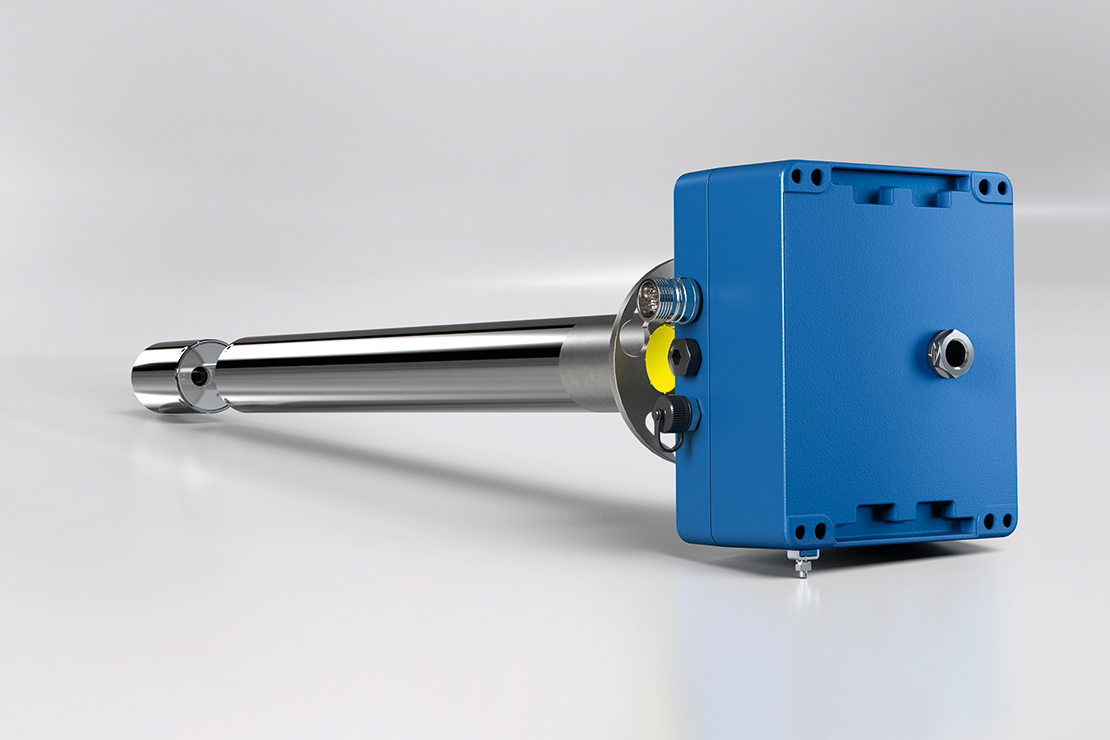

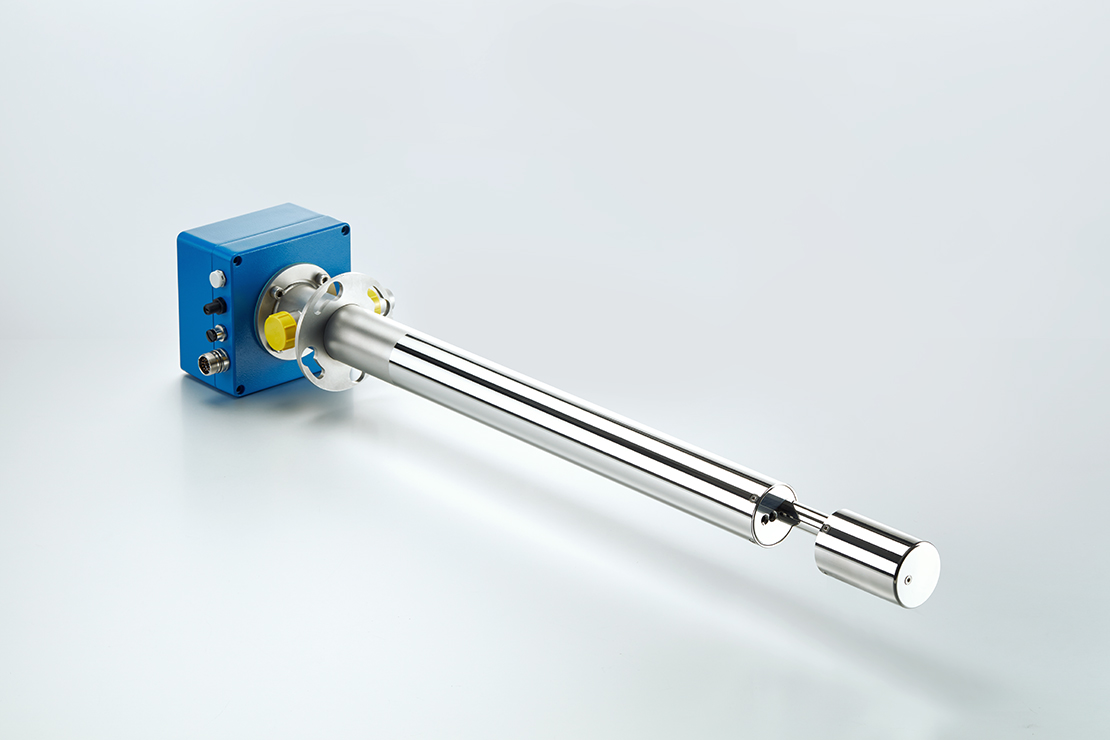

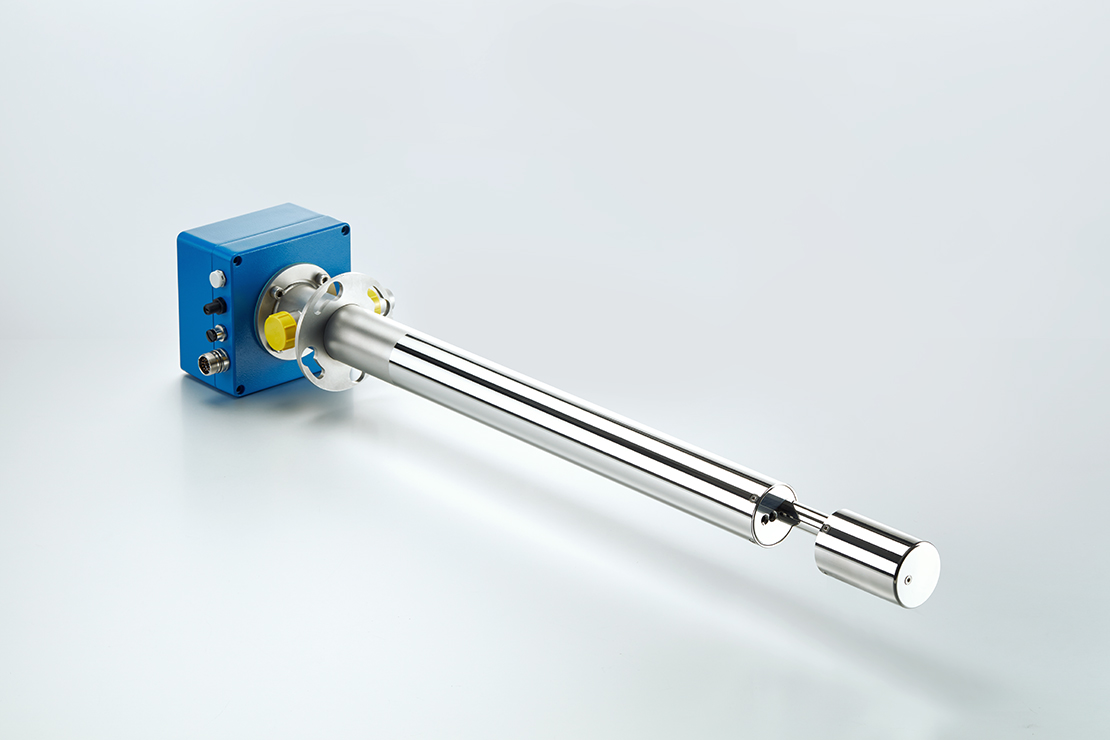

D-R 808

In situ dust monitor

Certified and approved PM CEMS providing very high quality monitoring of very low to medium particulate concentrations in dry flue gas flows.

Technology: Forward scattering

Request A QuoteFeatures

- Certified for the range of 0-7.5 mg/m3 the lowest range achievable for a dust CEMS (Continuous Emissions Monitoring System)

- Certified and approved dust analyzer for ensuring plant compliance with international standards for industrial emissions

- New: ATEX & IECEx certified to operate safely in hazardous environments, minimizing the risk of ignition and explosion

CERTIFICATIONS

- TÜV certified to EN 15267-1:2009, EN 15267-2:2009, EN 15267-3 :2007, EN 14181 :2014

- QAL1 as defined by EN14181

- QAL3 compliance to EN14181

- MCERTs certification for "Stack emissions monitoring equipment at industrial installations” – Continuous emissions monitoring systems (CEMS)

- ATEX (optional):

- II 3G Ex ec nC op is IIC T4 Gc

- II 3D Ex op is tc IIIC T100 °C Dc

-

IECEx (optional):

- Ex ec nC op is IIC T4 Gc

- Ex op is tc IIIC T100 °C Dc

- US EPA capable as a PM-CEMS or PM-CPMS

- Compliant with US EPA 40 CFR 60 PS 11

Benefits

- Advanced measurement accuracy:

Utilizes forward scattering technology to minimize cross sensitivity to particle type and size - Suitable for high temperature stacks and hazardous Ex zones:

Designed to operate effectively in extreme conditions - Single side installation:

Eliminates the need for optical alignment, making it ideal for thick-walled or double-walled ducts - User-friendly flange:

Easy installation and maintenance; Simply unscrew, turn slightly, and remove the instrument from the stack/duct - Simplified audit process:

Allows for easy verification with manual filters, ensuring consistent and accurate performance checks without removing the device from the stack - Status-dependent indicator light on the analyzer:

Changes color to reflect the operational state of the analyzer, providing clear and immediate visual feedback - Pressure-controlled purge air system:

Ensures that the particulate analyzer remains safeguarded in the event of a blower or plant instrument air system failure - Durable construction with no moving parts in the flue gas flow:

Ensures long-lasting reliability and minimal maintenance - Reduced maintenance and operational costs:

The robust design and minimal maintenance requirements significantly lower the overall cost of ownership and operation

Application

Typical applications:

Suitable for process applications and for emission compliance for plants equipped with bag filters, cartridge filters, cyclones, electrostatic precipitators, or without any filtration

- Ideal for monitoring non-condensing / dry flue gases

- Monitoring of dust arrestment filter plants

- Monitoring of ventilation systems

Industries:

- Waste to energy plants

- Metal industries, including steel and aluminum production

- Mineral processing, such as cement and gypsum manufacturing

- Chemical industries, including TiO2 production and refineries

- Power generation plants, including coal, gas and biomass plants

Technical data

| Parameter | Details |

|---|---|

| Measuring Principle | Forward scattering, in-situ, continuous, single-sided installation |

| Measuring Variable | Scattered light units, calibratable as dust concentration in mg/m³ |

| Measuring Range | 0 … 300 mg/m³ |

| Certified Measuring Range | 0 … 7.5 mg/m³ |

| Certificates | QAL1 (TÜV and MCERTS) |

| Standards | IED 2010/75/EU, EN 15267‑1/2/3, EN 14181, US EPA 40 CRF 60 PS 11, 13th/17th/27th/30th BImSchV, TA Luft |

| Interface |

Analogue output: 1× 4–20 mA, max 400 Ohm, potential-free (adjustable) Digital output: 2× NC/NO, max 60 VDC, 30 VAC, 0.5 A (adjustable) RS 485 Modbus RTU, USB |

| Nominal Voltage | 24 V– |

| Ambient Conditions |

Installation location: Indoor or outdoor Temperature: -40 … +60 °C |

| Operating Conditions |

In duct: Temperature: Max 350 °C (optional 500 °C) Relative humidity: 0–95%, non-condensing Relative pressure: -50 … +50 hPa |

| Dimensions |

Inner duct diameter: > 0.3 m (representative measurement required) Wall thickness: Max 0.47 m |

| Check Functions | Automatic zero/reference point measurement, contamination detection/compensation, purge air monitoring |

| Degree of Protection | IP65 (DIN EN 60529) |

| Light Source | Laser, class 2 (DIN EN 60825‑1), < 1 mW at 650 nm |

| Connections |

Process: Flange DN 40 PN6, stud bolts, 100 mm bolt circle Device: M23 DURAG standard Purge air hose: Ø 25 mm Purge air sensor: M12 8-pin |

| Operation and Display |

Status display: LED D-ESI 100 software or D-ISC 100 operating unit |

| Material |

Probe: 1.4404, AISI 316L, polished Housing: Painted aluminum |

* Additional interfaces with D‑ISC 100 operating unit

** Weather protection cover required for outdoor installation

*** Enables remote access via web interface, requires PC with Windows operating system

System components

| Component |

|---|

| D-R 808 dust monitor |

| D-ESI 100 software * |

| D-TB 200 terminal box |

| D-TB 100 terminal box ** |

| D-ISC 100 P operating and purge air unit |

* Enables remote access via web interface, requires PC with Windows operating system

** External purge air supply required

Explosion protection

| Standard | Certification |

|---|---|

| ATEX |

II 2G Ex px op is IIC T4 Gb II 3G Ex pz op is IIC T4 Gc II 3D Ex pD III T70 °C Dc |

| IECEx | Ex pzc IIC T4 Gc |

Accessories

Mandatory

- D-TB x00

- D‐ESI 100

Recommended

- D-ISC 100 xx2

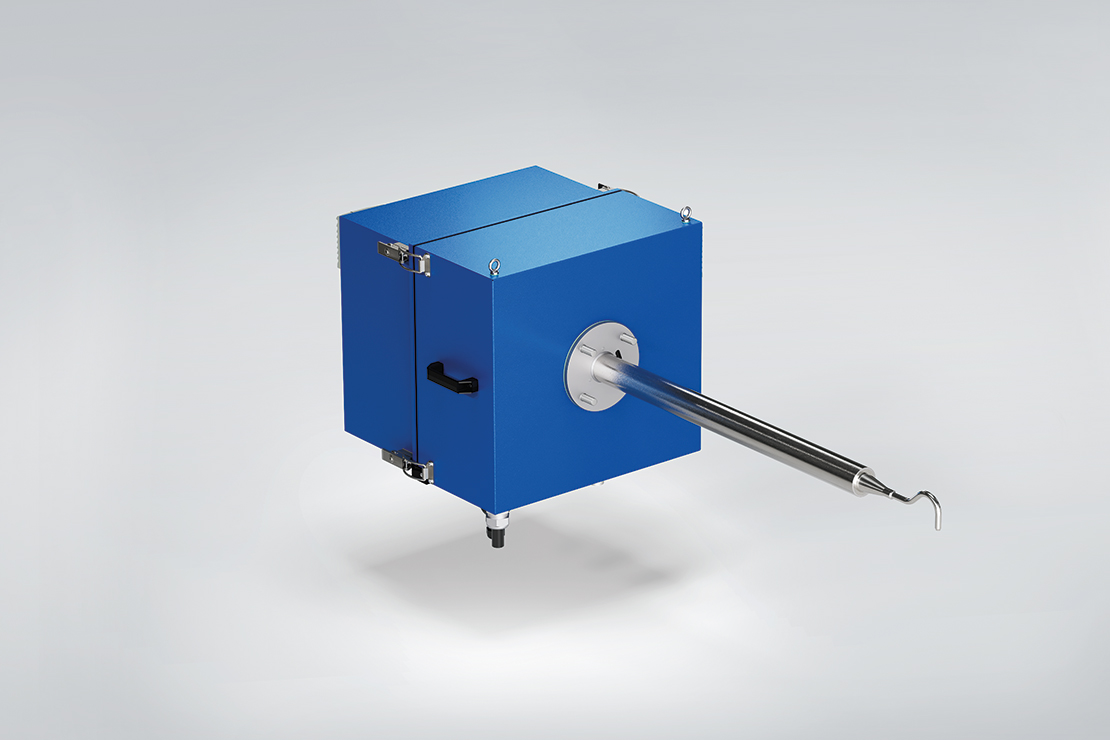

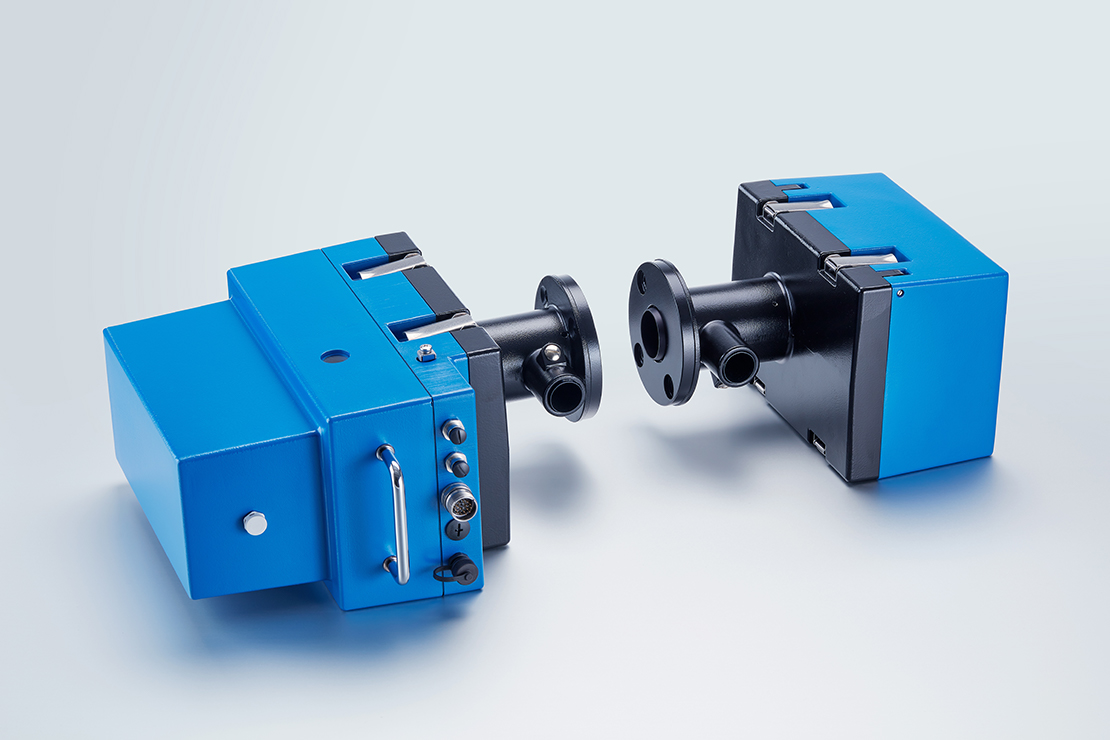

LaserCEM

Multi-gas monitoring system

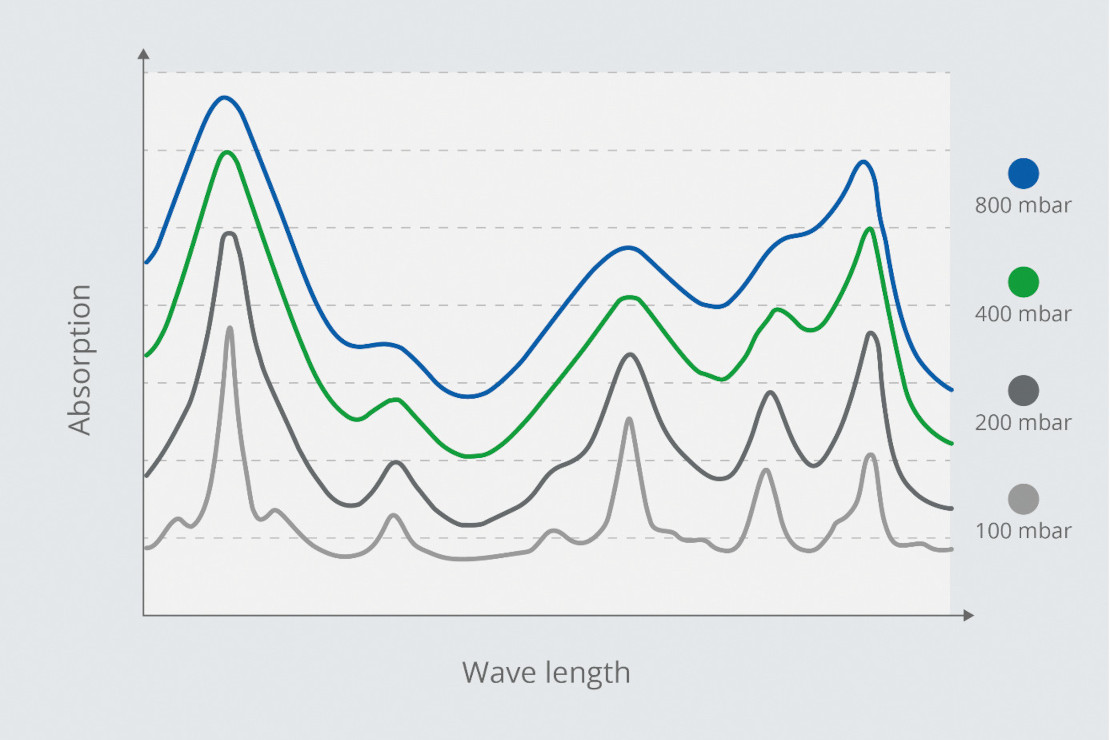

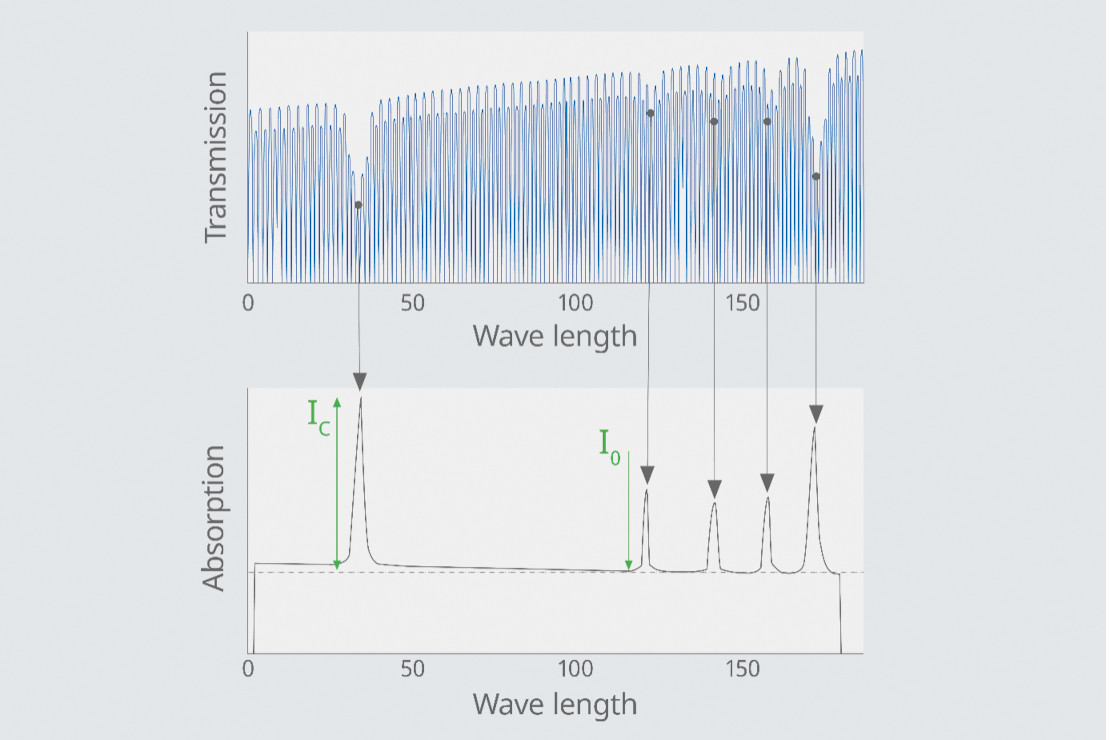

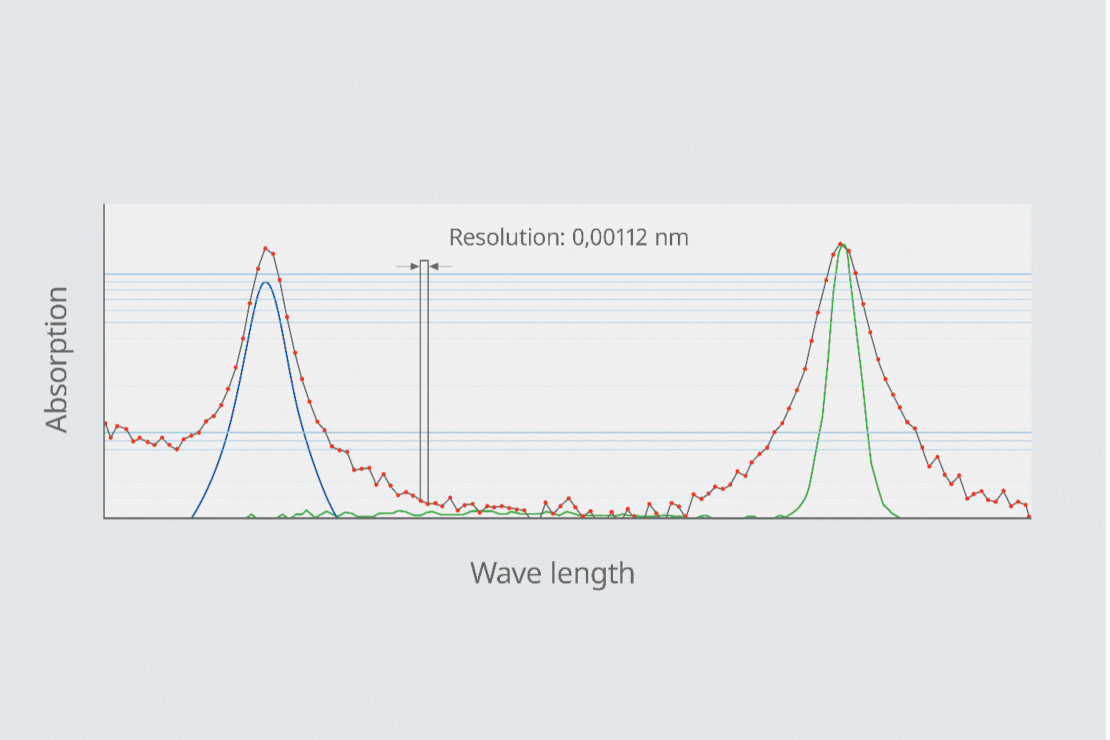

The LaserCEM® is a turnkey multi-gas stack emissions monitor for environmental compliance, using two patented technologies: OFCEAS® (Optical Feedback Cavity Enhanced Absorption Spectroscopy) and LPS® (Low Pressure Sampling).

The combination of OFCEAS® and LPS® technologies enables high spectral analysis that is interference-free, fast, and highly accurate, whatever the gas matrix to be analyzed. Its Low Pressure Sampling makes the LaserCEM® adapted to a wide range of applications without the need to heat or dry the sample prior to analysis, considerably reducing the risk of pollutants interferences or losses, as well as installation, operating and maintenance costs.

US-EPA capable, QAL1 certified and fully pre-calibrated, the LaserCEM® continuous multigas analyzer is the perfect choice for CEMS applications.

Technology: Optical Feedback Cavity Enhanced Absorption Spectroscopy (OFCEAS) and Low Pressure Sampling (LPS)

Request A QuoteFeatures

- The LaserCEM® can measure a wide choice of parameters with an unforeseen quality of measurement in terms of accuracy and resolution: HF, HCl, NH3, CH4, SO2, CO, CO2, NO, NO2, O2, N2O, H2S, CHOH, H2O…

- Double QAL1 certification (by TÜV and MCERTS) according to EN 15267 and EN 14181; incorporates the QAL3 functionalities defined by EN 14181

- Lowest certified measuring ranges for hydrogen fluoride (HF), for nitrogen monoxide (NO), and for carbon monoxide (CO)

- Direct measurement without modifying the sample

- Measurement of interferents or normalization gases (water, oxygen) with the same analyzer

- Low energy, calibration gases and compressed air consumption

- Utilizes low-pressure sampling and traced lines to prevent condensation and eliminate washout effect

- Communication, control and maintenance via Modbus, (TCP/IP, RS), analog, USB and Ethernet

Benefits

- Comprehensive stack emissions management:

LaserCEM® continuous emission monitoring system combines regulatory compliance, low cost of ownership, low maintenance, high availability, and environmental responsibility to provide a comprehensive approach to your stack emissions management. - True direct extractive CEMS:

No sample pre-treatment. OFCEAS technology associated with low pressure sampling enables direct measurement and eliminates the risk of chemical adsorption, desorption, and condensation along the sampling line. Accurate measurement even in high water contents (>80%). - Low cost of ownership:

Dust filters’ replacement drastically reduced; low use of compressed air and calibration gases; very low energy consumption (80 °C temperature maintained traced sampling line compared to 180 °C required by other monitoring systems). - Easy to use, easy to report emissions:

LaserCEM® is able to analyze all kind of gases and concentration ranges. In combination with DURAG DATA SYSTEMS' emission DAHS, the D-EMS 2020, tracking ELVs and sharing emissions reports with your local authority is amazingly simple. - Evolutive, futureproofed:

Modular system, allowing for the add of new gas parameters or new ranges: you to stay fit and compliant with future regulations or stack emissions monitoring objectives.

Application

Perfectly suitable for continuous stack emission measurements for environmental compliance in all type of industries:

- Waste to energy plants (municipal, biomedical and sludge incinerators, hazardous waste incinerators at chemical or pharmaceutical plants)

- Energy from Solid Recovered Fuels (SRF) or Refuse-derived Fuel (RDF)

- Metal industries, including steel, green steel and aluminum production or recycling

- Power generation: Hydrogen power plants, coal-fired power stations, gas turbines, biomass plants...

- Mineral processing, such as cement and gypsum, brick, tiles and glass manufacturing

- Emissions from oil and gas operations in Net Zero transitions

- Chemical industries, including fertilizer production

- Treatment and remediation of contaminated soil, Residual Hazardous Materials (RHM), contaminated water and residual material

- Refineries, including ancillary sources and non-refinery process units

- Gasification and pyrolysis processes

- Oxy-fuel combustion

- DeSOx & DeNOx, FGD emission monitoring

- Efficiency control of air pollutants abatement systems

- Low NOx and ultra-low NOx measurements

Technical data

Compounds and measuring ranges

| Parameter | Certified Measuring Range | Typical Maximum Ranges |

|---|---|---|

| CO (mg/m³) | 0 … 75; 0 … 1,249 | 0 … 3,000 |

| CO low (mg/m³) | 0 … 30; 0 … 250 | - |

| CO₂ (Vol.-%) | - | 0 … 20 |

| NO (mg/m³) | 0 … 78; 0 … 150; 0 … 2,008 | 0 … 3,000 |

| NO₂ (mg/m³) | 0 … 40; 0 … 100 | 0 … 2,000 |

| N₂O (mg/m³) | - | 0 … 500 |

| HF (mg/m³) | 0 … 1.5; 0 … 10 | 0 … 100 |

| SO₂ (mg/m³) | 0 … 75; 0 … 2,858 | 0 … 5,000 |

| HCl (mg/m³) | 0 … 15; 0 … 98 | 0 … 150 |

| NH₃ (mg/m³) | 0 … 15; 0 … 45; 0 … 76 | 0 … 500 |

| CH₄ (mg/m³) | 0 … 5; 0 … 20 | 0 … 500 |

| O₂ (Vol.-%) | 0 … 21 | 0 … 25 |

| H₂O (Vol.-%) | 0 … 30; 0 … 40 | 0 … 60 |

| H₂S (mg/m³) | - | 0 … 100; 0 … 7,500 |

| CHOH (mg/m³) | - | 0 … 5; 0 … 30 |

| TOCs by FID | On request | On request |

* Certification in accordance with EN 15267‑3, QAL1 by TÜV + MCERTs

** Concentrations based on standard conditions 1,013.25 hPa and 0 °C

Performances

| Linearity | < 2% range |

| Repeatability | < 1% range |

| Response Time | < 200 s (all gases) |

| Drift Zero/Span | < 3.0% (all gases); O2 < 0.2 vol-% |

Analyzer

| Power Supply | 110 … 230 VAC, 50 … 60 Hz, 150 VA + 10 to 45 VA/m of sampling line (consumption) |

| Compressed Air Supply | Dust free, oil free, dry, at ambient temperature; 3 barg pressure at max 5.5 l/min flow, required only in maintenance mode |

| Ambient Conditions | Temperature: +5 … +40 °C Humidity: 10 … 90% relative humidity, non-condensing |

| Communication Interfaces | USB ports, Modbus TCP, RS232, RS485 (RJ45), VGA, 4 … 20 mA Remote Access Via Ethernet |

Sampling system

| Technology | Low pressure sampling (LPS®) |

| Sampling Line | Function of the ambient temperature, unheated sampling line or traced line temperature maintained at max 80 °C; maximum length 150 m |

| Sampling Probe |

Includes filter and sonic nozzle Material: Inconel 600, other materials on request Length: variable, tailor-made |

| Process Connection | DN65 PN16 flange, stainless steel (316L) |

| Sampling Box |

Dimensions (H x W x D): 44 x 40 x 18 cm Degree of protection: IP65 |

| Flue Gas |

Temperature: +5 … +600 °C Absolute humidity: 0 … 80% vol., higher water content on request |

Turnkey LaserCEM® cabinet

| 24U | 134 x 60 x 91 cm |

| 38U | 183 x 60 x 80 cm |

Accessories

Mandatory

- Sampling probe

- Sampling line

- Pumping system

Optional

- Integration in cabinet

- Air conditioning system

- Analog outputs

- QAL3 module for zero and span calibration

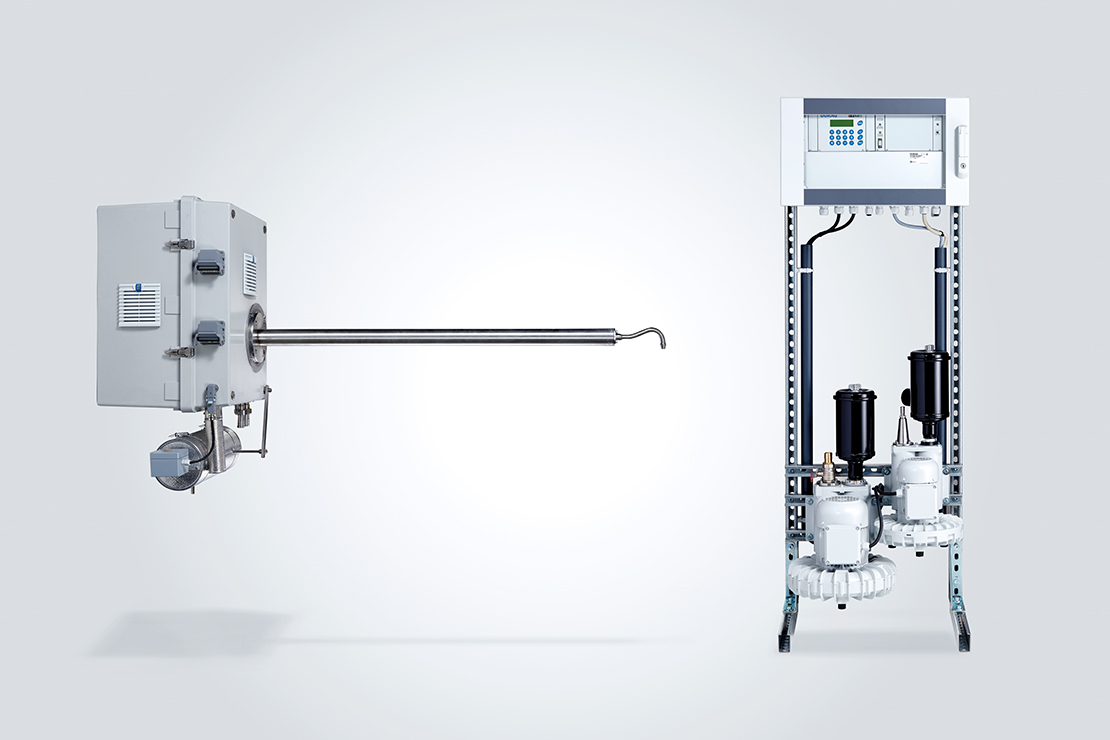

HM-1400 TRX 2

Total mercury analyzer

Total mercury analyzer for continuous process and emission monitoring. With option for separate determination of elemental and oxidized mercury species.

Functionality: Atomic absorption spectroscopy

Request A QuoteFeatures

- Lowest certified measuring range 0 … 15 µg/m³

- Measuring principle allows separate determination of elemental and oxidized mercury

- Automatic check functions via internal reference gas generator

- Low consumption of energy and instrument air

- Simple, robust design

Benefits

- Suitable for official emission monitoring

- Reliable measurement of small and large mercury concentrations

- Measuring data of both mercury species for use in evaluation of mercury mitigation measures

- Low operating costs over the entire product lifecycle

- Easy maintenance and operation

Application

- Official continuous emission monitoring

- Real-time measurement of emissions and process concentrations

Technical data

| Measuring Principle | Extractive total mercury measurement via thermocatalytic conversion and atomic absorption spectroscopy |

| Measuring Variable | Total mercury concentration in µg/m³ |

| Measuring Range | 0 … 3,000 µg/m³ |

| Certified Measuring Range | 0 … 15 µg/m³, 0 … 45 µg/m³, 0 … 75 µg/m³ |

| Ambient Conditions |

Temperature: - Sampling: -20 … +50 °C - Analyzer: +0 … +50 °C |

| Operating Conditions (In Duct) |

Temperature: Max 300 °C Relative Humidity: 0 … 100% Relative Pressure: -50 … +20 hPa |

| Inner Duct Diameter | Minimum 0.5 m |

| Operation and Display |

Operating unit in front door Remote access from PC using TCP/IP |

| Check Functions |

Automatic leakage check Automatic zero point check with ambient air Automatic reference point check with internal HgCl₂ reference gas generator Manual reference point check with external reference gas generator |

USP

- Measuring principle allows separate determination of mercury species (speciation)

Accessories

Mandatory

- Sampling probe

- Sampling tube

- Sample gas line

Optional

- Pre-filter (for sampling probe, at high dust concentrations)

- D-EMS

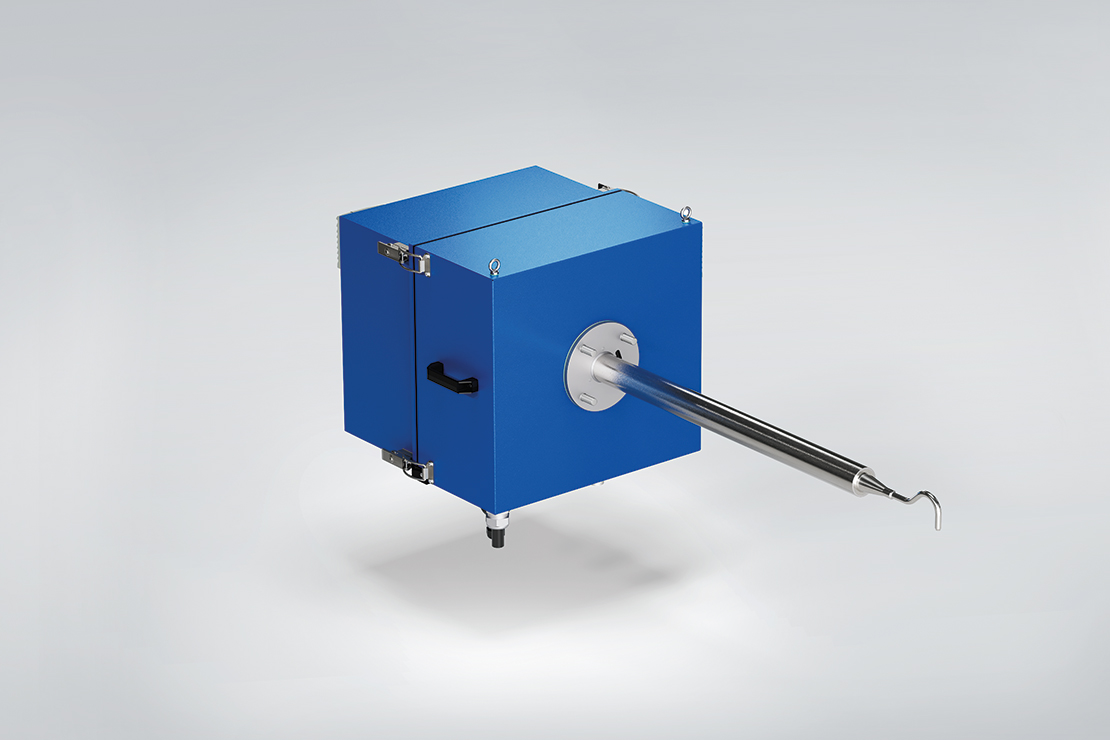

D-FL 100

Volume flow measuring system

For continuous volume flow measurement in dry gases. Reliable, even under extreme operating conditions.

Functionality: Differential pressure principle

Request A QuoteFeatures

- Continuous measurement of velocity and volume flow

- Double-sided installation for measurement over the entire duct diameter or cost-saving single-sided installation

- Robust and resistant probe material for use in aggressive gases or at high temperatures (optional)

- Probe individually adapted to the application

- Automatic back purging unit (optional)

- Automatic internal self-test

Benefits

- Certified for official emission monitoring

- Precise measurement of velocity and volume flow even under demanding operating conditions

- Space-saving and easy single-sided installation (optional)

- Suitable for use in potentially explosive atmospheres (optional)

- Suitable for use in hot gases

Application

Perfectly suitable for continuous stack emission measurements for environmental compliance in all type of industries:

- Continuous emission monitoring in hot or aggressive gases

- Continuous emission monitoring in small to large duct diameters

- Continuous emission monitoring in explosive atmospheres

- Volume flow measurement for process control and process optimization

Technical data

Compounds and measuring ranges

| Measuring Principle | Differential pressure measuring principle, in-situ measurement, continuous measurement, single-sided or double-sided installation |

| Measuring Variable | Differential pressure, velocity, volume flow, volume flow (standardized), temperature, pressure |

| Measuring Range |

Velocity: 3 … 50 m/s Volume flow: 0 … 3,000,000 m³/h |

| Certified Measuring Range | 3 … 30 m/s (certified), 3 … 50 m/s (additional) |

| Ambient Conditions |

Ambient temperature: - Certified: -40 … +50 °C - Optional: -40 … +60 °C |

| Operating Conditions (In Duct) |

Temperature: Max 850 °C Relative humidity: 0 … 95%, non-condensing Relative pressure: -50 … +50 hPa Dust concentration: Max 30 / 100 / 150 mg/m³ (depending on probe version) |

| Dimensions |

Inner duct diameter: 0.4 … 9 m Wall thickness: Max 300 / 800 / 1,300 mm (depending on probe version) |

| Interfaces |

Analogue output: 1× 4 … 20 mA, max 400 Ohm, potential-free Digital output: 2× NC/NO, max 60 VDC, 30 VAC, 0.5 A Modbus RS 485 RTU, USB |

| Operation and Display | Software D-ESI 100, operating unit D-ISC 100 (optional), status LED (optional) |

| Check Functions | Automatic internal self-test |

| Nominal Voltage | 24 VDC |

| Degree of Protection |

Evaluation unit: IP65 (housing) / IP20 (top-hat rail module) Differential pressure sensor: IP67 |

Explosion protection

| D-FL 100-20 | II 2 GD Ex d IIC T5 Gb Ex tb T100°C Db (optional) |

| Differential pressure sensor | II 1/2 G Ex ia IIC T6 … T4 Ga/Gb (optional) |

System components

| Probe D-FL 100 with accessories |

| Differential pressure sensor D-FL 100 DDM |

| Evaluation unit D-FL 100-20 |

| Pressure sensor D-FL 100 ADM (optional) |

| Temperature sensor D-XT (optional) |

| Software D-ESI 100* or Operating unit D-ISC 100** |

| Weather protection (optional for outdoor installation) |

| Automatic back purging unit (optional) |

* Enables remote access via web interface, PC with Windows operating system required

** Additional interfaces with D-ISC 100 operating unit

Accessories

Mandatory

- D-ESI 100

Recommended

- D-ISC 100 xx2

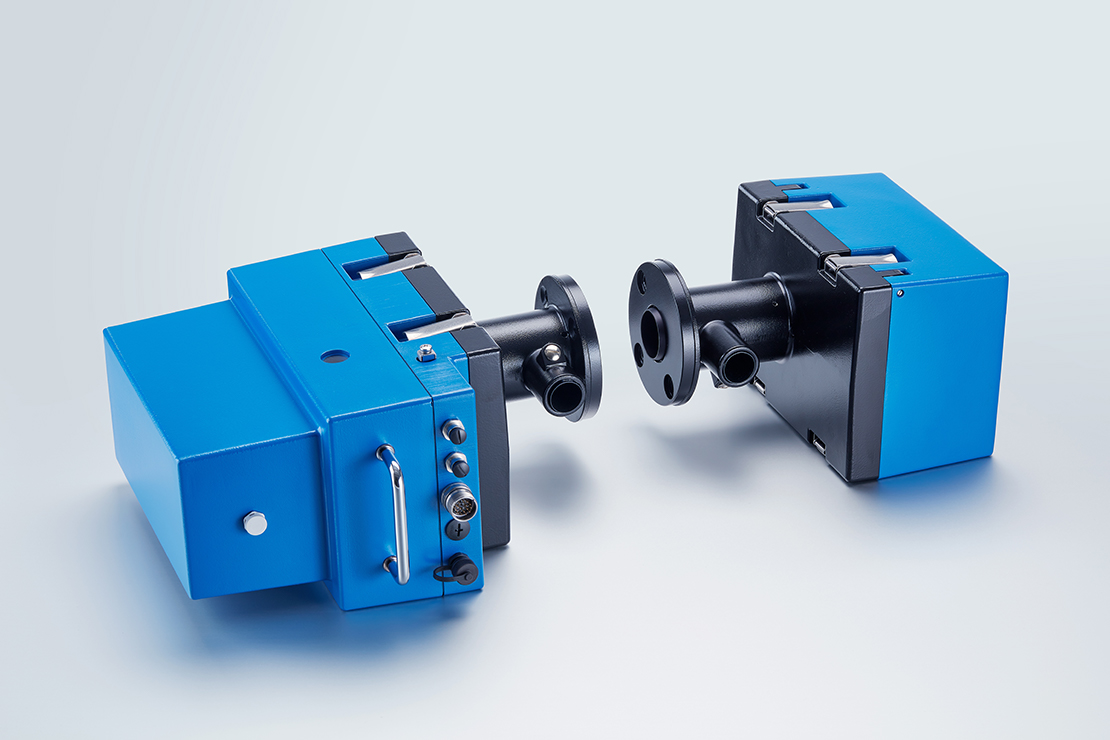

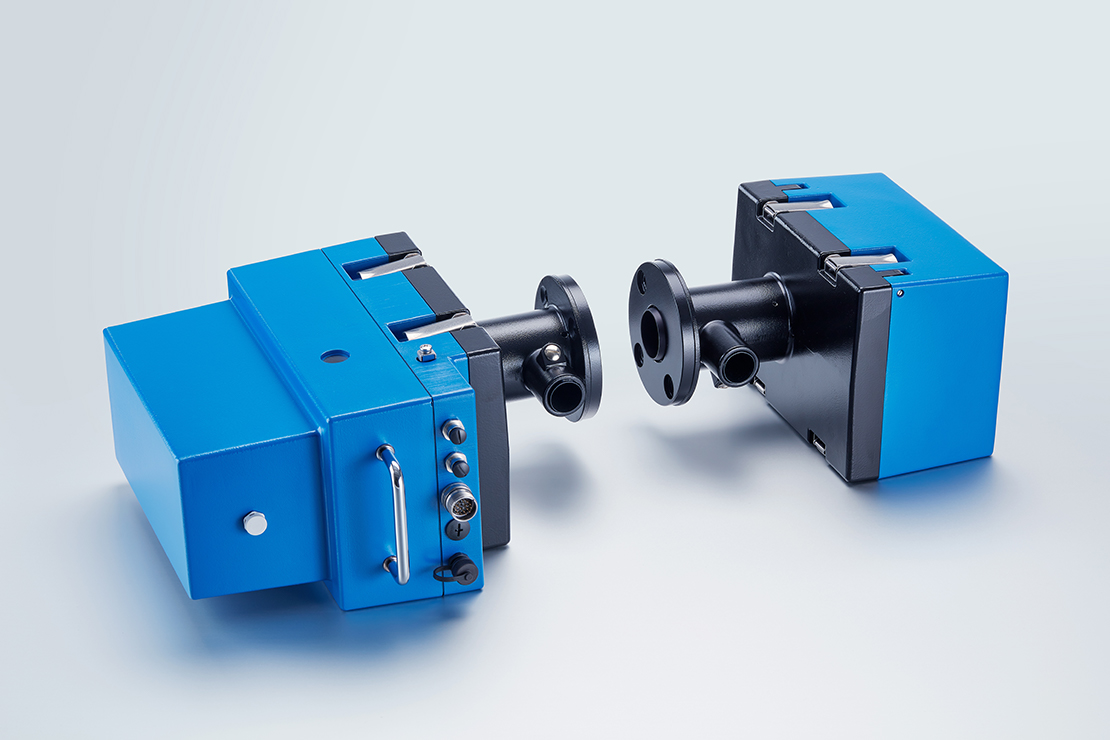

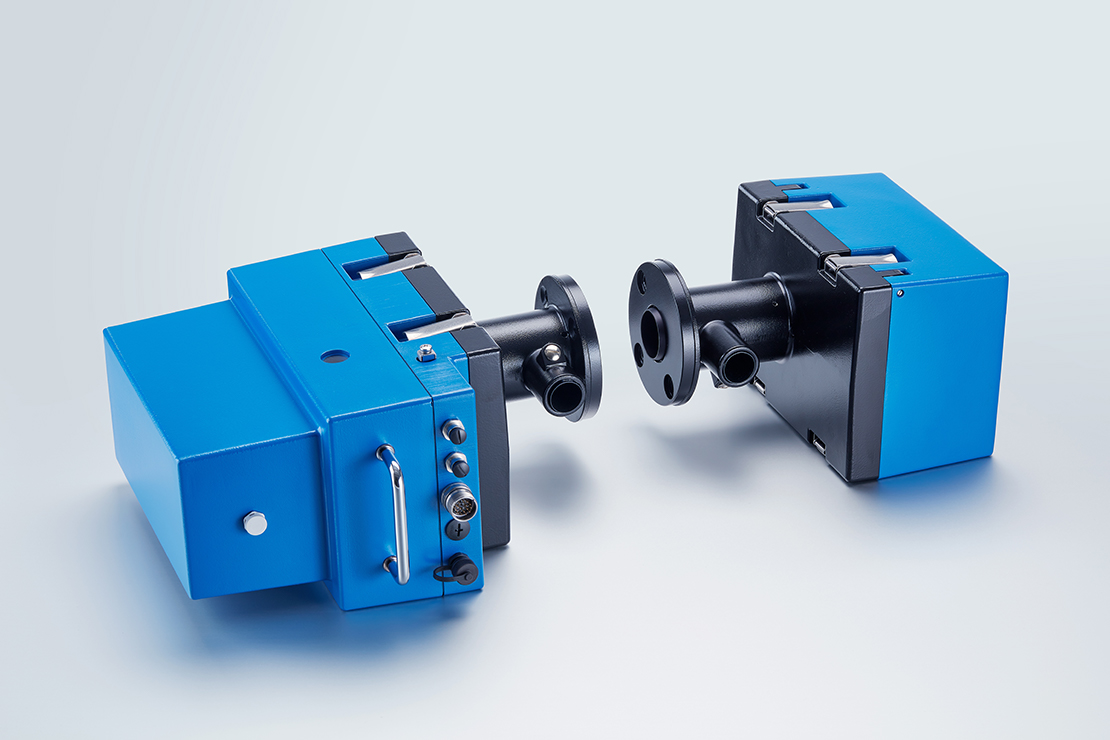

D-FL 220

Volume flow measuring system

For continuous, contactless volume flow measurement in dry and humid gases. Reliable, even under demanding operating conditions.

Functionality: Ultrasonic transit time difference method

Request A QuoteFeatures

- Continuous measurement of velocity and volume flow

- Contactless measurement

- Corrosion-resistant ultrasonic transducers

- Measurement over the entire duct diameter

- Automatic check functions

Benefits

- Certified for official emission monitoring

- Precise measurement of gas velocity and volume flow

- Suitable for measurement in humid and aggressive gases

- Long life time and high availability even under extreme plant conditions

- Low maintenance

Application

Perfectly suitable for continuous stack emission measurements for environmental compliance in all type of industries:

- Continuous emission monitoring in humid and aggressive gases

- Continuous emission measurement in small to very large duct diameters

- Volume flow measurement for process control and process optimization

Technical data

| Measuring Principle | Ultrasonic transit time difference method, in-situ measurement, continuous measurement, double-sided installation, contactless measurement |

| Measuring Variable | Volume flow (operation), volume flow (standardized), velocity, temperature |

| Measuring Range |

Velocity: 0 … 40 m/s Volume flow: 0 … 5,000,000 m³/h |

| Certified Measuring Range | 0 … 30 m/s |

| Ambient Conditions |

Ambient temperature: - Measuring device: -40 … +70 °C - Certified: -40 … +60 °C Relative humidity: 0 … 95%, non-condensing |

| Operating Conditions (In Duct) |

Temperature: Max 300 °C Relative humidity: 0 … 100%, condensation permissible Relative pressure: -50 … +20 hPa |

| Dimensions |

Inner duct diameter: 0.5 … 14 m (depending on operating conditions) Wall thickness: Max 800 mm |

| Interfaces |

Analogue output: 1× 4 … 20 mA, max 400 Ohm, potential-free Digital output: 2× NC/NO, max 60 VDC, 30 VAC, 0.5 A Modbus RS 485 RTU, USB |

| Operation and Display | Software D-ESI 100, operating unit D-ISC 100, status LED |

| Check Functions | Automatic zero point and reference point measurement |

| Nominal Voltage | 24 VDC |

| Degree of Protection | IP65 |

System components

| 2 measuring devices D-FL 220 |

| Purge air unit D-BL |

| Terminal Box D-TB 100 |

| Software D-ESI 100* or |

| Operating unit D-ISC 100** |

| Weather protection (optional for outdoor installation) |

* Enables remote access via web interface, PC with Windows operating system required

** Additional interfaces with D-ISC 100 operating unit

Accessories

Mandatory

- D-TB 100

- D-ESI 100

Recommended

- D-ISC 100 xx2

D-R 909

Extractive dust monitor

Extractive continuous dust measurement of small to medium dust concentrations in wet flue and process gases even under difficult plant conditions.

D-R 220

Dust and opacity monitor

The cost-effective solution for continuous, contactless dust and opacity measurement at medium to high concentrations in dry flue and process gases.

D-R 290

Dust and opacity monitor

For continuous, contactless dust and opacity measurement at medium to high concentrations in dry flue and process gases. Also suitable for difficult plant conditions.

D-R 820 F

Dust monitor

Extractive measurement of wet flue or process gases. For monitoring small to medium dust concentrations.

D-EMS 2020

Environmental and process data management system

Data acquisition and handling system (DAHS) for the acquisition, calculation, long-term storage and visualization of data in the most diverse areas. Compliant with European and US EPA-based regulations.

D-R 320

In situ dust monitor

For continuous, contactless measurement of low to medium dust concentrations in dry flue and process gases. Also suitable for corrosive gases and potentially explosive atmospheres.

D-R 808

In situ dust monitor

Certified and approved PM CEMS providing very high quality monitoring of very low to medium particulate concentrations in dry flue gas flows.

D-R 909

Extractive dust monitor

Extractive continuous dust measurement of small to medium dust concentrations in wet flue and process gases even under difficult plant conditions.

Functionality: Forward scattering

Request A QuoteFeatures

- QAL1-certified in accordance with EN 15267

- Automatic control functions

- Flow-optimized design prevents the deposit of impurities

- Efficient operation due to electronically controlled blowers and heaters

- Modular system of compact units

Benefits

- Suitable for official emission monitoring

- Low service cost for calibration and maintenance

- Low energy cost

- Easy and versatile installation

Applications

- Emission measurement of wet flue gases

- Measurement of wet process gases with small to medium dust concentrations

Technical data

| Parameter | Description |

|---|---|

| Measuring principle | Extraction of sample gas, dilution and heating for evaporation of water droplets, forward scattering, single-sided installation |

| Measuring variable | Scattered light units, calibratable as dust concentration in mg/m³ |

| Measuring range | Minimum 0 … 5 mg/m³; Maximum 0 … 200 mg/m³ |

| Certified measuring ranges | 0 … 7,5 mg/m³; 0 … 15 mg/m³; 0 … 45 mg/m³; 0 … 100 mg/m³ |

| Ambient conditions | Installation location: Indoor or outdoor installation* Temperature: -40 … +60 °C |

| Operating conditions | Temperature: 0 … 160 °C (Higher temperature values on request) Relative humidity: 0 … 100% and maximum 70 g/m³ water as aerosol Relative pressure: -50 … +50 hPa** |

| Inner duct diameter | Minimum: 0.2 m |

| Interface | Analog output: 1x 4 … 20 mA, maximum 500 Ω, potential-free Analog input: 1x 4 … 20 mA, maximum 250 Ω, potential-free Digital output: 2x NC/NO, maximum 60 V_, 30 V~, 0.5 A Modbus RS 485 RTU USB |

| Operation and display | Status LED |

| Software | D-ESI 100*** |

| Optional | Control Unit D-ISC 100 |

| Control functions | Automatic zero point and reference point measurement, automatic contamination measurement and compensation |

| Light source | Laser, class 2 in accordance with EN 60825-1, < 1 mW at 650 nm |

* Weather protection required for outdoor installation

** Depending on flue gas velocity and operating mode

*** Enables remote access via web interface, requires PC with Windows operating system

D-R 220

Dust and opacity monitor

The cost-effective solution for continuous, contactless dust and opacity measurement at medium to high concentrations in dry flue and process gases.

Functionality: Transmission

Request A QuoteFeatures

- Continuous dust measurement

- Contactless measurement

- Automatic check functions

- High-quality corrosion-free plastic housing and a wide ambient temperature range

Benefits

- Easy installation for opacity monitoring and reliable emission monitoring

- Reliable measurement of medium to large dust concentrations

- Space-saving and easy installation

- Transmission measuring principle opens up a wide range of applications

- Also for use under extreme sample gas conditions

Applications

- Emission measurement of dry flue gases at the stack

- Measurement of dry flue gases in the process

- Corrosive flue gases, challenging gas matrix

- Measurement of dry process gases

Technical Data

| Parameter | Description |

|---|---|

| Measuring principle | Transmission, contactless and in-situ measurement |

| Measuring variable | Extinction, opacity, calibratable as dust concentration in mg/m³ |

| Measuring range | Opacity: 0 … 100% Extinction: 0 … 1.6 Dust concentration: 0 … 5,000 mg/m³ |

| Certified measuring range | n/a |

| Ambient conditions | Installation location: Indoor or outdoor installation** Temperature: -20 … +50 °C |

| Operating conditions | In duct: Temperature: Maximum 200 °C, optional: 500 °C Relative humidity: 0 … 95%, non-condensing Relative pressure: -50 … +10 hPa (standard) -50 … +50 hPa (optional) |

| Inner duct diameter | 0.4 … 10 m |

| Interface* | Analogue output: 1x 4 … 20 mA, maximum 400 Ohm, potential-free (various parameters adjustable) Digital output: 2x NC/NO, maximum 60 VDC, 30 VAC, 0.5 A (various parameters adjustable) RS 485 Modbus RTU, USB |

| Status display | LED |

| Operation and display | Software D-ESI 100*** or Operating unit D‑ISC 100 |

| Check functions | Automatic zero point and reference point measurement, manual contamination and linearity measurement (optional) |

| Light source | LED |

* Additional interfaces with D‑ISC 100 operating unit

** Weather protection cover required for outdoor installation

*** Enables remote access via web interface, PC with Windows operating system required

System components

| Component | Description |

|---|---|

| Dust monitor D-R 220 | Measuring head and reflector |

| Software D-ESI* | Measurement software for control and monitoring* |

| Terminal Box with purge air unit | D-TB 200 |

| Terminal Box without purge air unit | D-TB 100* |

| Operating and purge air unit | D-ISC 100 P |

* Enables remote access via web interface, PC with Windows operating system required

USP

- High quality at a low price

Accessories

Mandatory

- D-TB x00

- D‐ESI 100

- D-BL

Recommended

- D-ISC 100 xx2

D-R 290

Dust and opacity monitor

For continuous, contactless dust and opacity measurement at medium to high concentrations in dry flue and process gases. Also suitable for difficult plant conditions. Exceeds EPA and ASTM standards.

Functionality: Transmission

Request A QuoteFeatures

- Continuous dust measurement

- Smallest certified measuring range 0 … 15 mg/m³

- Automatic measurement and correction of contamination

- Automatic check functions

- Contactless measurement

- Maintenance and linearity check without disassembly

- Exceeds EPA and ASTM standards The D-R 290 was developed to comply with 40CFR60, App. B, PS-1 and ASTM D6216-20 Annex A1 “Standard Practice for Opacity Manufactures to Certify Conformance with Design and Performance Specifications."

Benefits

- Suitable for official emission monitoring

- Reliable measurement of medium to large dust concentrations

- Space-saving and easy installation

- Long life time and high availability under extreme plant conditions

Applications

- Emission measurement of dry flue gases at the stack

- Temperatures up to 1,000 °C

- Corrosive flue gases, plants with complex gas matrix

- Measurement of dry process gases

Technical Data

| Property | Details |

|---|---|

| Measuring principle | Transmission, contactless and in-situ measurement |

| Measuring variable | Extinction, opacity, calibratable as dust concentration in mg/m³ |

| Measuring range |

Opacity: Minimum 0 … 20%, maximum 0 … 100% Extinction: Minimum 0 … 0.1, maximum 0 … 2.0 Dust concentration: Minimum 0 … 80 mg/m³, maximum 0 … 4,000 mg/m³ |

| Certified measuring range | 0 … 15 mg/m³ |

| Ambient conditions |

Installation location: Indoor or outdoor installation Temperature: -40 … +60 °C (Standard) -30 … +60 °C (ATEX) -20 … +60 °C (IECEx) |

| Operating conditions |

In duct: Temperature: Maximum 250 °C, optional: 1,000 °C Relative humidity: 0 … 95%, non-condensing Relative pressure: -50 … +20 hPa, -50 … 0 hPa (ATEX/IECEx) |

| Inner duct diameter | 0.5 … 18 m |

| Interface |

Analogue output: 1x 4 … 20 mA, maximum 400 Ohm, potential-free (various parameters adjustable) Digital output: 2x NC/NO, maximum 60 VDC, 30 VAC, 0.5 A (various parameters adjustable) RS 485 Modbus RTU, USB Status display: LED |

| Operation and display | Software D-ESI 100 or Operating unit D-ISC 100 |

| Check functions | Automatic zero point and reference point measurement, automatic contamination measurement and compensation |

| Light source | LED, 450 … 680 nm |

* Additional interfaces with D‑ISC 100 operating unit

** Weather protection cover required for outdoor installation

*** Measuring section > 1 m

Explosion protection

| Certification | Details |

|---|---|

| ATEX |

II 2G Ex pxb IIC T4 Gb II 3G Ex pzc IIC T4 Gc II 3D Ex pD IIIC T100°C Dc |

| IECEx | Ex pzc IIC T4 Gc |

System components

| Component | Description |

|---|---|

| Dust Monitor | D-R 290 (measuring head and reflector) |

| Purge Air Unit(s) | D-BL |

| Software | D-ESI* and Terminal Box without purge air unit |

| Terminal Box | D-TB 100** or Operating unit D‑ISC 100 |

* Enables remote access via web interface, PC with Windows operating system required

** External purge air supply required

D-R 820 F

Dust monitor

Extractive measurement of wet flue or process gases. For monitoring small to medium dust concentrations.

Functionality: Forward scattering

Request A QuoteFeatures

- Dilution of the sample

- Hyperkinetic gas extraction

- Single-sided installation on stack

- Automatic zero point and reference point check

- Automatic measurement of contamination and correction of measured values

- Local control panel and LC display

Benefits

- Suitable for plants with variable gas velocity

- Long life time due to stable laser light source

- Easy commissioning, adjustment and maintenance without PC

Applications

- Emission measurement of wet flue gases

- Measurement of wet process gases with small to medium concentrations

Technical Data

| Specification | Details |

|---|---|

| Measuring Principle | Extraction of sample gas, dilution and heating for evaporation of H2O, forward scattering, single-sided installation |

| Measuring Variable | Stray light units, calibratable as dust concentration in mg/m³ |

| Measuring Range | Minimum 0 … 15 mg/m³, Maximum 0 … 200 mg/m³ |

| Certified Measuring Range | 0 … 15 mg/m³ |

| Ambient Conditions | Installation location: Indoor or outdoor installation Temperature: -20 … +50 °C |

| Operating Conditions | In duct: Temperature: -25 … 220 °C Relative humidity: > 95 %, maximum 30 g/m³ H2O as aerosol Relative pressure: -30 … +2 hPa |

| Inner Duct Diameter | Minimum 0.4 m |

| Interface | Analogue output: 4x 4 … 20 mA, maximum 1,000 Ohm, potential-free Digital output: 4x NC/NO, maximum 35 VDC, 0.4 A |

| Operation and Display | Supply and display unit on the measuring device |

| Check Functions | Automatic zero point and reference point measurement, automatic contamination measurement and compensation |

| Light Source | Laser diode, red, 650 nm |

* Weather protection cover required for outdoor installation

System components

(Bullet) Dust monitor D-R 820 F (including blower unit and supply and display unit)

USP

- Suitable for extreme plant conditions

- Low lifecycle costs

D-EMS 2020

Environmental and process data management system

Data acquisition and handling system (DAHS) for the acquisition, calculation, long-term storage and visualization of data in the most diverse areas. Compliant with European and US EPA-based regulations.

The D-EMS 2020 system is an environmental and process data management system which meets today’s legal requirements and is conceptually prepared for future guidelines. The system enables the acquisition, calculation, long-term storage and visualization of environmental data and process data in the most diverse areas.

Functionality: The system is modular in structure and makes it possible to implement a wide range of user-specific solutions. All calculations, storage and display take place within the D-EMS 2020 server. Additional workstations or clients can be connected via network with diverse functions.

Functionality: Forward scattering

Request A QuoteFeatures

- New: Since December 2024, tested according to EN 17255

- Complies with European and US EPA based regulations

- Analog and digital data acquisition with long-term data storage in accordance with legal requirements

- Provision of data to customer systems via analog and digital interface

- Presentation of current, historical or forecast measurement data as bar or line chart and optionally in customer-specific design

- Standalone and client-server architecture, installation options to meet the various customer requirements

- Role-based user management, including LDAP(S)

- Additional modules such as GHG, QAL3, automatic backup, and many more

Certifications

- EN 15267 (QAL1)

- MCERTS

Conformities Germany

- TA Luft

- 1. BImSchV

- 2. BImSchV

- 13. BImSchV

- 17. BImSchV

- 27. BImSchV

- 30. BImSchV, 31. BImSchV

- BEP 2017

- Statuskennung und Klassierung (SKK) 2019

- DIN EN 14181

- MVO (DEHSt)

- VDI 4201

Conformities EU

- 2010/75/EU (IED)

- (EU) 2015/2193 (MCP)

- EN 14181

- EN 17255

- And other national requirements

Conformities US

- US EPA 40 CFR Part 60

- US EPA 40 CFR Part 63

- US EPA 40 CFR Part 75

- And other US EPA-based evaluations

Benefits

- Scalable and modular system for all plant sizes and types

- Fully-featured modern system design

- Intuitive and easy-to-use interface

- Flexible configuration to meet the various customer requirements

- Powerful reporting with multiple customization options and e-mail notification

- Complies with European and US EPA based regulations

Technical data

| Specification | Details |

|---|---|

| Data Acquisition |

Per server up to 1024 analog inputs Per server up to 1024 analog outputs Per server up to 2048 analog inputs Per server up to 2048 analog outputs Data acquisition can be carried out either directly or via data loggers in the D-MS 500 FC family to the server. |

| Interfaces |

4-20mA Modbus RTU / TCP Profibus DP Profibus Master (VDI 4201) Profinet Elan OPC UA Mode 4 Ethernet IP And others |

| Data Export | PDF, XLS, XML, CSV files |

| Data Security |

Data buffer in the D-MS 500 FC data logger family with internal ring memory of up to 128 days Encrypted data communication between server and data loggers Encrypted and password protected SQL database Role-based user management, including LDAP(S) External data storage and backup (file server, NAS, etc.) Alarm notification on failure of a storage medium |

| Internet/Intranet Connection |

Automatic data transfer to any web server on the Internet for visualization via HTML Daily data control |

| Visualization |

Reporting (daily, monthly, quarterly, yearly, etc.) Bar and line charts with current and historical data Alarm and event management with comment functionality and e-mail notification |

D-R 320

In situ dust monitor

For continuous, contactless measurement of low to medium dust concentrations in dry flue and process gases. Also suitable for corrosive gases and potentially explosive atmospheres.

Technology: Backward scattering

Request A QuoteFeatures

- Continuous dust measurement

- Smallest certified measuring range 0 … 7.5 mg/m³

- Single-sided installation without optical alignment

- Automatic check functions

- Continuous, integrated purge air monitoring and control

- Maintenance and linearity check without disassembly

- Contactless measurement

Benefits

- Suitable for official emission monitoring

- Reliable measurement of small dust concentrations

- Space-saving and easy installation

- Long life time and high availability under extreme plant conditions

- Low maintenance

Application

- Emission measurement of dry flue gases at the stack

- Temperatures up to 600 °C

- Corrosive flue gases, plants with complex gas matrix

- Measurement of dry process gases with small concentrations

Technical data

| Parameter | Details |

|---|---|

| Measuring Principle | Backward scattering, single-sided installation, contactless and in-situ measurement |

| Measuring Variable | Stray light units, calibratable as dust concentration in mg/m³ |

| Measuring Range |

Minimum: 0 … 5 mg/m³ Maximum: 0 … 200 mg/m³ |

| Certified Measuring Range | 0 … 7.5 mg/m³ |

| Ambient Conditions |

Installation location: Indoor or outdoor installation** Temperature: -40 … +60 °C -30 … +60 °C (ATEX) -20 … +60 °C (IECEx) |

| Operating Conditions |

In duct: Temperature: Maximum 600 °C Relative humidity: 0 … 95%, non-condensing Relative pressure: -50 … +50 hPa -50 … 0 hPa (ATEX/IECEx) |

| Dimensions |

Inner duct diameter: Minimum 0.7 m Wall thickness: Maximum 0.56 m |

| Interface* |

Analogue output: 1x 4 … 20 mA, max 400 Ohm, potential-free (adjustable) Digital output: 2x NC/NO, max 60 VDC, 30 VAC, 0.5 A (adjustable) RS 485 Modbus RTU, USB Status display: LED |

| Operation and Display |

Software D-ESI 100*** or Operating unit D-ISC 100 |

| Check Functions |

Automatic zero and reference point measurement Automatic contamination measurement and compensation Integrated purge air monitoring and control |

| Protective Functions | Integrated fail-safe shutter (optional) |

| Light Source | Laser, class II, < 1 mW at 650 nm |

* Additional interfaces with D-ISC 100 operating unit

** Weather protection cover required for outdoor installation

*** Enables remote access via web interface, PC with Windows operating system required

Explosion protection

| Standard | Certification |

|---|---|

| ATEX |

II 2G Ex px op is IIC T4 Gb II 3G Ex pz op is IIC T4 Gc II 3D Ex pD III T70 °C Dc |

| IECEx | Ex pzc IIC T4 Gc |

System components

| Component | Description |

|---|---|

| Main Unit | Dust monitor D-R 320 |

| Software | D-ESI* |

| Connection Options |

Terminal Box with purge air unit D-TB 200 or Terminal Box without purge air unit D-TB 100** or Operating and purge air unit D-ISC 100 P |

* Enables remote access via web interface, PC with Windows operating system required

** External purge air supply required

USP

- Patented design, without alignment of optical components after installation

Accessories

Mandatory

- D-TB x00

- D‐ESI 100

Recommended

- D-ISC 100 xx2

D-R 808

In situ dust monitor

Certified and approved PM CEMS providing very high quality monitoring of very low to medium particulate concentrations in dry flue gas flows.

Technology: Forward scattering

Request A QuoteFeatures

- Certified for the range of 0-7.5 mg/m3 the lowest range achievable for a dust CEMS (Continuous Emissions Monitoring System)

- Certified and approved dust analyzer for ensuring plant compliance with international standards for industrial emissions

- New: ATEX & IECEx certified to operate safely in hazardous environments, minimizing the risk of ignition and explosion

CERTIFICATIONS

- TÜV certified to EN 15267-1:2009, EN 15267-2:2009, EN 15267-3 :2007, EN 14181 :2014

- QAL1 as defined by EN14181

- QAL3 compliance to EN14181

- MCERTs certification for "Stack emissions monitoring equipment at industrial installations” – Continuous emissions monitoring systems (CEMS)

- ATEX (optional):

- II 3G Ex ec nC op is IIC T4 Gc

- II 3D Ex op is tc IIIC T100 °C Dc

-

IECEx (optional):

- Ex ec nC op is IIC T4 Gc

- Ex op is tc IIIC T100 °C Dc

- US EPA capable as a PM-CEMS or PM-CPMS

- Compliant with US EPA 40 CFR 60 PS 11

Benefits

- Advanced measurement accuracy:

Utilizes forward scattering technology to minimize cross sensitivity to particle type and size - Suitable for high temperature stacks and hazardous Ex zones:

Designed to operate effectively in extreme conditions - Single side installation:

Eliminates the need for optical alignment, making it ideal for thick-walled or double-walled ducts - User-friendly flange:

Easy installation and maintenance; Simply unscrew, turn slightly, and remove the instrument from the stack/duct - Simplified audit process:

Allows for easy verification with manual filters, ensuring consistent and accurate performance checks without removing the device from the stack - Status-dependent indicator light on the analyzer:

Changes color to reflect the operational state of the analyzer, providing clear and immediate visual feedback - Pressure-controlled purge air system:

Ensures that the particulate analyzer remains safeguarded in the event of a blower or plant instrument air system failure - Durable construction with no moving parts in the flue gas flow:

Ensures long-lasting reliability and minimal maintenance - Reduced maintenance and operational costs:

The robust design and minimal maintenance requirements significantly lower the overall cost of ownership and operation

Application

Typical applications:

Suitable for process applications and for emission compliance for plants equipped with bag filters, cartridge filters, cyclones, electrostatic precipitators, or without any filtration

- Ideal for monitoring non-condensing / dry flue gases

- Monitoring of dust arrestment filter plants

- Monitoring of ventilation systems

Industries:

- Waste to energy plants

- Metal industries, including steel and aluminum production

- Mineral processing, such as cement and gypsum manufacturing

- Chemical industries, including TiO2 production and refineries

- Power generation plants, including coal, gas and biomass plants

Technical data

| Parameter | Details |

|---|---|

| Measuring Principle | Forward scattering, in-situ, continuous, single-sided installation |

| Measuring Variable | Scattered light units, calibratable as dust concentration in mg/m³ |

| Measuring Range | 0 … 300 mg/m³ |

| Certified Measuring Range | 0 … 7.5 mg/m³ |

| Certificates | QAL1 (TÜV and MCERTS) |

| Standards | IED 2010/75/EU, EN 15267‑1/2/3, EN 14181, US EPA 40 CRF 60 PS 11, 13th/17th/27th/30th BImSchV, TA Luft |

| Interface |

Analogue output: 1× 4–20 mA, max 400 Ohm, potential-free (adjustable) Digital output: 2× NC/NO, max 60 VDC, 30 VAC, 0.5 A (adjustable) RS 485 Modbus RTU, USB |

| Nominal Voltage | 24 V– |

| Ambient Conditions |

Installation location: Indoor or outdoor Temperature: -40 … +60 °C |

| Operating Conditions |

In duct: Temperature: Max 350 °C (optional 500 °C) Relative humidity: 0–95%, non-condensing Relative pressure: -50 … +50 hPa |

| Dimensions |

Inner duct diameter: > 0.3 m (representative measurement required) Wall thickness: Max 0.47 m |

| Check Functions | Automatic zero/reference point measurement, contamination detection/compensation, purge air monitoring |

| Degree of Protection | IP65 (DIN EN 60529) |

| Light Source | Laser, class 2 (DIN EN 60825‑1), < 1 mW at 650 nm |

| Connections |

Process: Flange DN 40 PN6, stud bolts, 100 mm bolt circle Device: M23 DURAG standard Purge air hose: Ø 25 mm Purge air sensor: M12 8-pin |

| Operation and Display |

Status display: LED D-ESI 100 software or D-ISC 100 operating unit |

| Material |

Probe: 1.4404, AISI 316L, polished Housing: Painted aluminum |

* Additional interfaces with D‑ISC 100 operating unit

** Weather protection cover required for outdoor installation

*** Enables remote access via web interface, requires PC with Windows operating system

System components

| Component |

|---|

| D-R 808 dust monitor |

| D-ESI 100 software * |

| D-TB 200 terminal box |

| D-TB 100 terminal box ** |

| D-ISC 100 P operating and purge air unit |

* Enables remote access via web interface, requires PC with Windows operating system

** External purge air supply required

Explosion protection

| Standard | Certification |

|---|---|

| ATEX |

II 2G Ex px op is IIC T4 Gb II 3G Ex pz op is IIC T4 Gc II 3D Ex pD III T70 °C Dc |

| IECEx | Ex pzc IIC T4 Gc |

Accessories

Mandatory

- D-TB x00

- D‐ESI 100

Recommended

- D-ISC 100 xx2

D-EMS 2020

Environmental and process data management system

Data acquisition and handling system (DAHS) for the acquisition, calculation, long-term storage and visualization of data in the most diverse areas. Compliant with European and US EPA-based regulations.

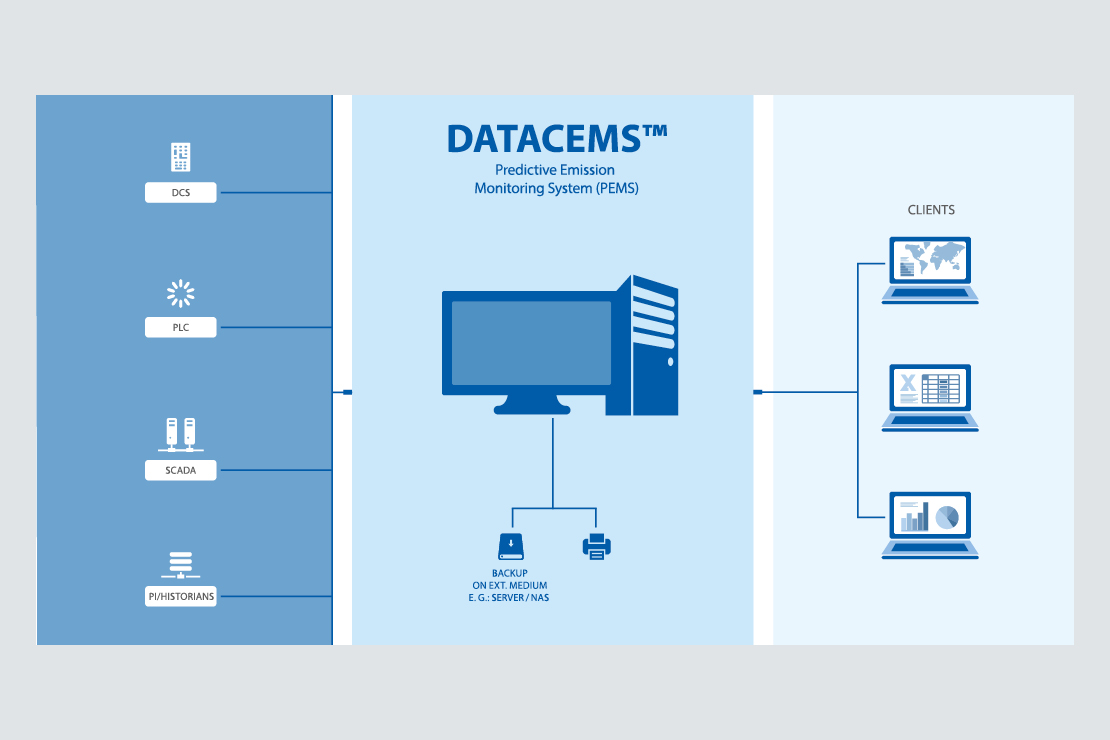

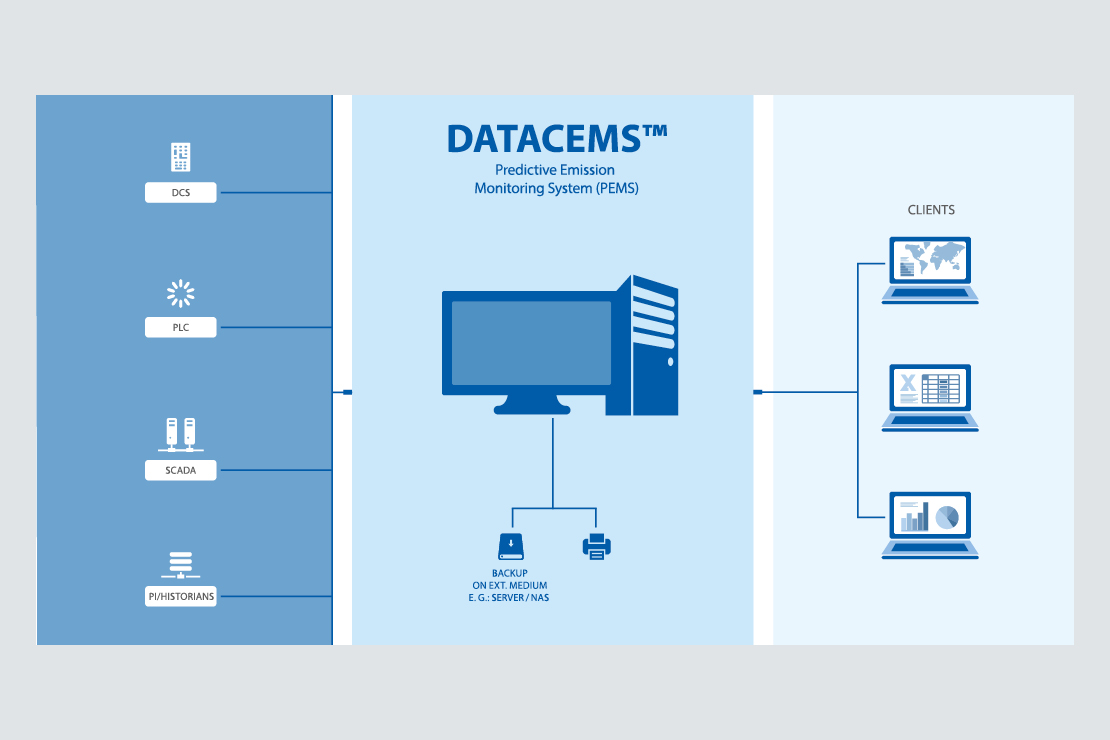

DATACEMS

Predictive emission monitoring system

Software-based PEMS for continuous real-time monitoring of pollutants such as NOX, SO2, CO, HC or reference variables such as O2.

D-EMS 2020

Environmental and process data management system

Data acquisition and handling system (DAHS) for the acquisition, calculation, long-term storage and visualization of data in the most diverse areas. Compliant with European and US EPA-based regulations.

The D-EMS 2020 system is an environmental and process data management system which meets today’s legal requirements and is conceptually prepared for future guidelines. The system enables the acquisition, calculation, long-term storage and visualization of environmental data and process data in the most diverse areas.

Functionality: The system is modular in structure and makes it possible to implement a wide range of user-specific solutions. All calculations, storage and display take place within the D-EMS 2020 server. Additional workstations or clients can be connected via network with diverse functions.

Functionality: Forward scattering

Request A QuoteFeatures

- New: Since December 2024, tested according to EN 17255

- Complies with European and US EPA based regulations

- Analog and digital data acquisition with long-term data storage in accordance with legal requirements

- Provision of data to customer systems via analog and digital interface

- Presentation of current, historical or forecast measurement data as bar or line chart and optionally in customer-specific design

- Standalone and client-server architecture, installation options to meet the various customer requirements

- Role-based user management, including LDAP(S)

- Additional modules such as GHG, QAL3, automatic backup, and many more

Certifications

- EN 15267 (QAL1)

- MCERTS

Conformities Germany

- TA Luft

- 1. BImSchV

- 2. BImSchV

- 13. BImSchV

- 17. BImSchV

- 27. BImSchV

- 30. BImSchV, 31. BImSchV

- BEP 2017

- Statuskennung und Klassierung (SKK) 2019

- DIN EN 14181

- MVO (DEHSt)

- VDI 4201

Conformities EU

- 2010/75/EU (IED)

- (EU) 2015/2193 (MCP)

- EN 14181

- EN 17255

- And other national requirements

Conformities US

- US EPA 40 CFR Part 60

- US EPA 40 CFR Part 63

- US EPA 40 CFR Part 75

- And other US EPA-based evaluations

Benefits

- Scalable and modular system for all plant sizes and types

- Fully-featured modern system design

- Intuitive and easy-to-use interface

- Flexible configuration to meet the various customer requirements

- Powerful reporting with multiple customization options and e-mail notification

- Complies with European and US EPA based regulations

Technical data

| Specification | Details |

|---|---|

| Data Acquisition |

Per server up to 1024 analog inputs Per server up to 1024 analog outputs Per server up to 2048 analog inputs Per server up to 2048 analog outputs Data acquisition can be carried out either directly or via data loggers in the D-MS 500 FC family to the server. |

| Interfaces |

4-20mA Modbus RTU / TCP Profibus DP Profibus Master (VDI 4201) Profinet Elan OPC UA Mode 4 Ethernet IP And others |

| Data Export | PDF, XLS, XML, CSV files |

| Data Security |

Data buffer in the D-MS 500 FC data logger family with internal ring memory of up to 128 days Encrypted data communication between server and data loggers Encrypted and password protected SQL database Role-based user management, including LDAP(S) External data storage and backup (file server, NAS, etc.) Alarm notification on failure of a storage medium |

| Internet/Intranet Connection |

Automatic data transfer to any web server on the Internet for visualization via HTML Daily data control |

| Visualization |

Reporting (daily, monthly, quarterly, yearly, etc.) Bar and line charts with current and historical data Alarm and event management with comment functionality and e-mail notification |

DATACEMS

Predictive emission monitoring system

Software-based predictive emission monitoring system (PEMS) for continuous real-time monitoring of pollutants such as NOX, SO2, CO, HC or reference variables such as O2.

PEMS are an innovative and cost-effective approach to continuous monitoring of emission sources as an alternative to continuous emissions monitoring systems (CEMS).

Functionality: A predictive emission monitoring system cannot measure emissions directly and instead uses an empirical model to predict emissions based on historical and real-time process data.

Functionality: Forward scattering

Request A QuoteFeatures

- Software-based monitoring, monitoring of primary pollutants (NOX, SOX, CO) and O2, CO2, VOC, HCl, NH3, H2S etc.

- PEMS define the relationship between a number of characteristic process parameters for an emission source and the corresponding emission concentration.

- PEMS uses an empirical model to predict emissions based on historical and real-time process data.

- PEMS provide a reasonable alternative to CEMS (AMS) where there is a reliable and predictable correlation between plant operating conditions and emissions.

Conformities

- US EPA 40 CFR Part 60

- US EPA 40 CFR Part 75

- Performance Specification 16 (PS-16)

- CEN/TS 17198

Benefits

- Significantly lower capital expenditures

- A fraction the operating and maintenance costs of a CEMS

- Maintenance and repair costs virtually eliminated

- Manpower requirements significantly reduced. Plant staff can focus on operational issues

- Valid results for all operating conditions reflected in the model including startups or shutdowns

- Accuracy/precision equal to CEMS

- Resilient to missing inputs – sensor failure does not impair data availability

- Models can be built by staff on site or third party consultants

- PEMS can be used as diagnostic tool to lower emissions

Applications

PEMS are used in a wide variety of plants around the world, particularly in the United States, but also in the Middle East and some parts of Asia. In Europe, PEMS are currently only commonly found in selected countries.

PEMS solutions are industry independent and are able to deal with emissions from many different applications. However, fuels should not vary in their calorific values and composition. PEMS are typically used for gas and oil-fired plants in the utility, petrochemical, chemical and steel sectors or other industrial plants.

In particular they are tailored for:

- Gas or liquid-fired emission sources

- Boilers

- Turbines

- Reciprocal internal combustion engines (RICE)

- Biogas plants

- Duct burners

- Dryers

- Chemical oxidizers

- Regenerative thermal oxidizers

- Process heaters

- Olefin furnaces

- Crude oil heaters

- Kilns

- Ships

- Offshore plants

Suitable fuel types are for example:

- Fuel oils

- Natural gas

- Refinery gas

- Process gas

- Combined fuels

EDM 280

Environmental dust monitor for PM monitoring in ambient air

Latest generation optical aerosol spectrometer with unique detection limit and excellent counting efficiency. Suitable for real-time PM monitoring under any environmental conditions and at all sites.

EDM 180

Approved PM monitor

This approved environmental dust monitor is the leading product for measuring particulate matter concentration (PM10, PM2.5) in ambient air. It is in service in government networks and institutions in over 30 countries.

EDM 180+

Approved next generation PM monitor

Provides all features of the EDM 180 plus additional USB and Ethernet interfaces. This approved environmental dust monitor is the leading product for measuring particulate matter concentration (PM10, PM2.5) in ambient air. It is in service in government networks and institutions in over 30 countries.

Indoor WRAS

Indoor wide-range aerosol spectrometer

For high resolution particle measurements in laboratories covering a particle size range of 5 nm … 35 μm. Combines two technologies: SMPS+C for nanoparticles and the portable optical aerosol spectrometer 11-D for dust particles.

AirQualifier EDM 264-SVC

Mobile PM & SVC monitor