Combustion and Safety Monitoring

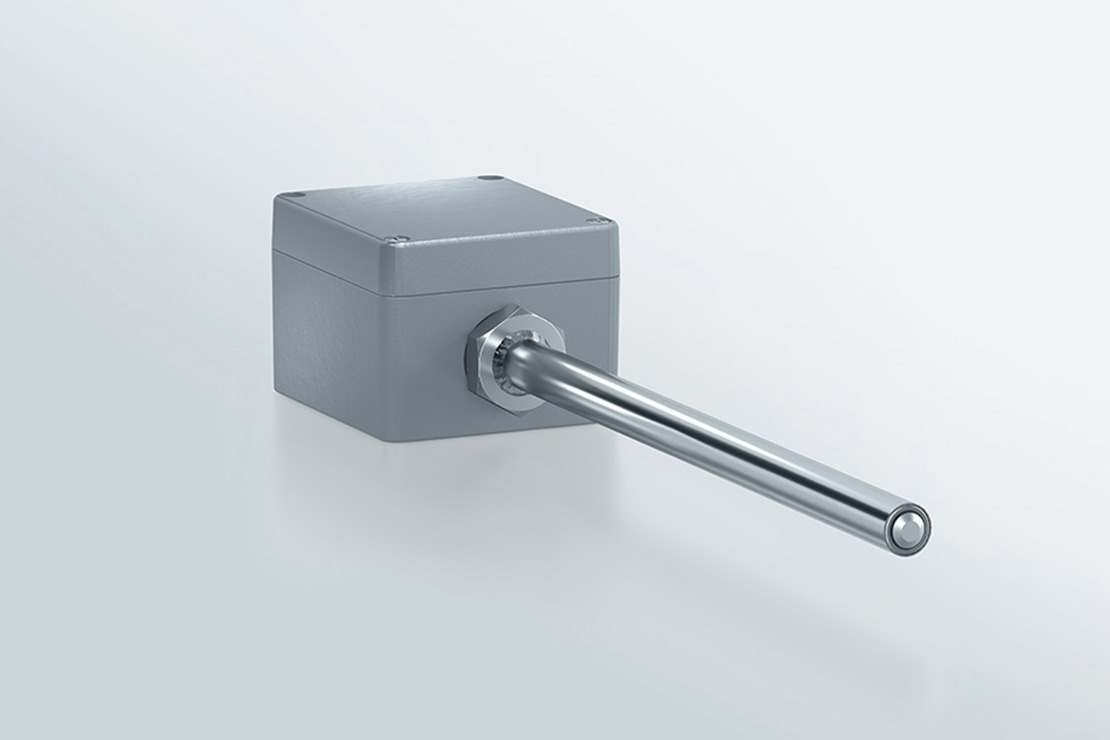

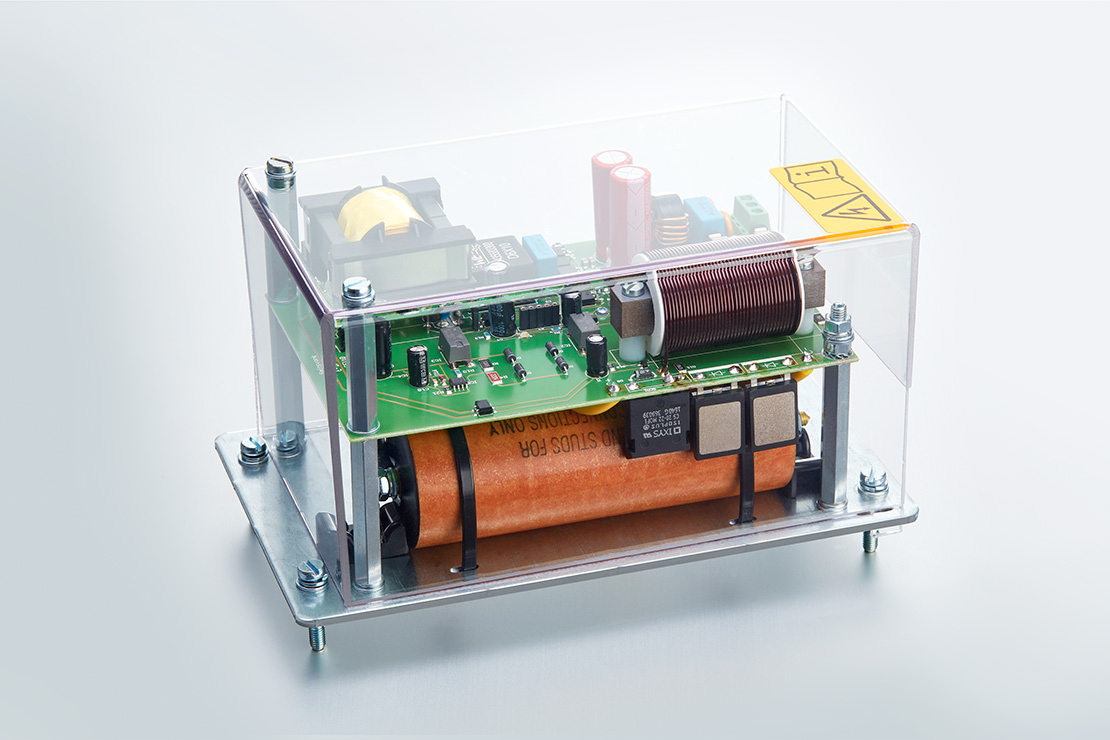

AAL 76

Ionization flame monitor

Simple, versatile and universal ionization flame monitor for a wide range of combustion systems. Universal connection to existing on-site ionization electrodes and controls.

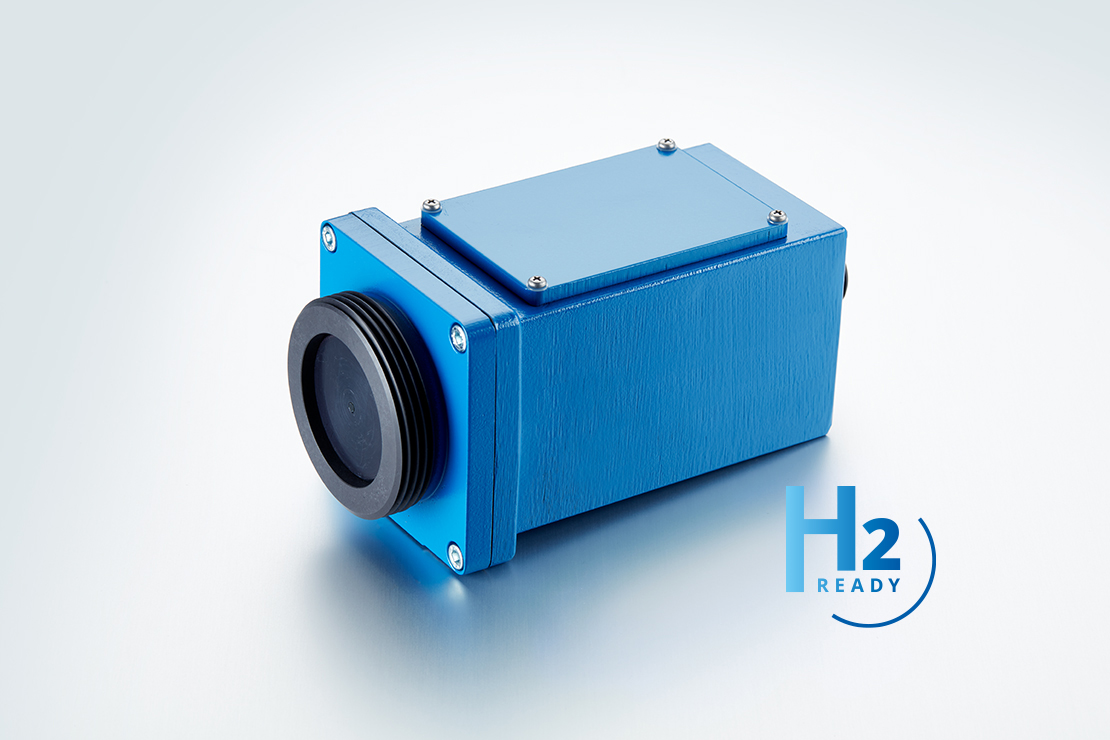

D-LX 110/710

Optical compact flame monitor

Easy, versatile and flexible compact flame monitor with integrated UV, VIS or IR flame sensor for monitoring gas, oil and coal flames. Particularly for applications with single burner view.

D-LX 201/721

Optical compact flame monitor

Flexible and selective compact flame monitor for high requirements. For optical monitoring of all fuel flames, including in complex multi-burner plants.

D-LX 200/720

Optical compact flame monitor

Flexible and selective compact flame monitor for high requirements. For optical monitoring of all fuel flames, including in complex multi-burner plants.

D-LE 103

Optical flame sensor

UV, VIS or IR flame sensor for combination with a control unit or burner control. For monitoring gas, oil and coal flames, particularly at single burner plants.

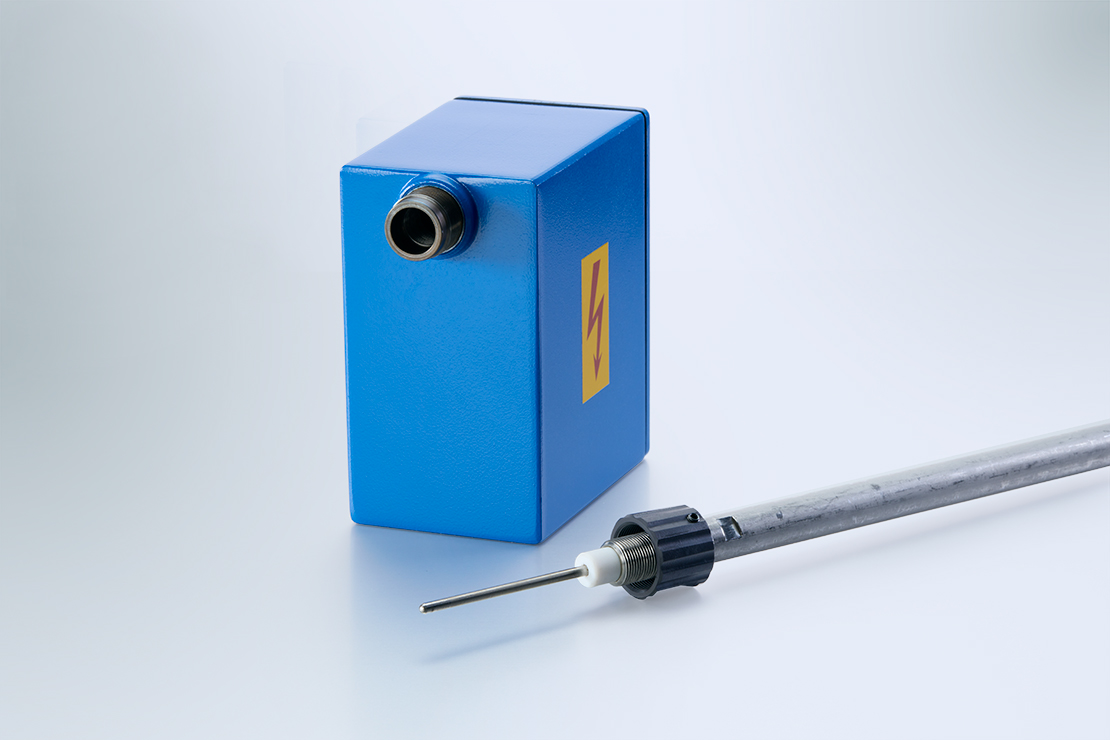

SPI

Portable high energy igniter

Durable and portable high energy ignition unit. With compact and lightweight design for easy use.

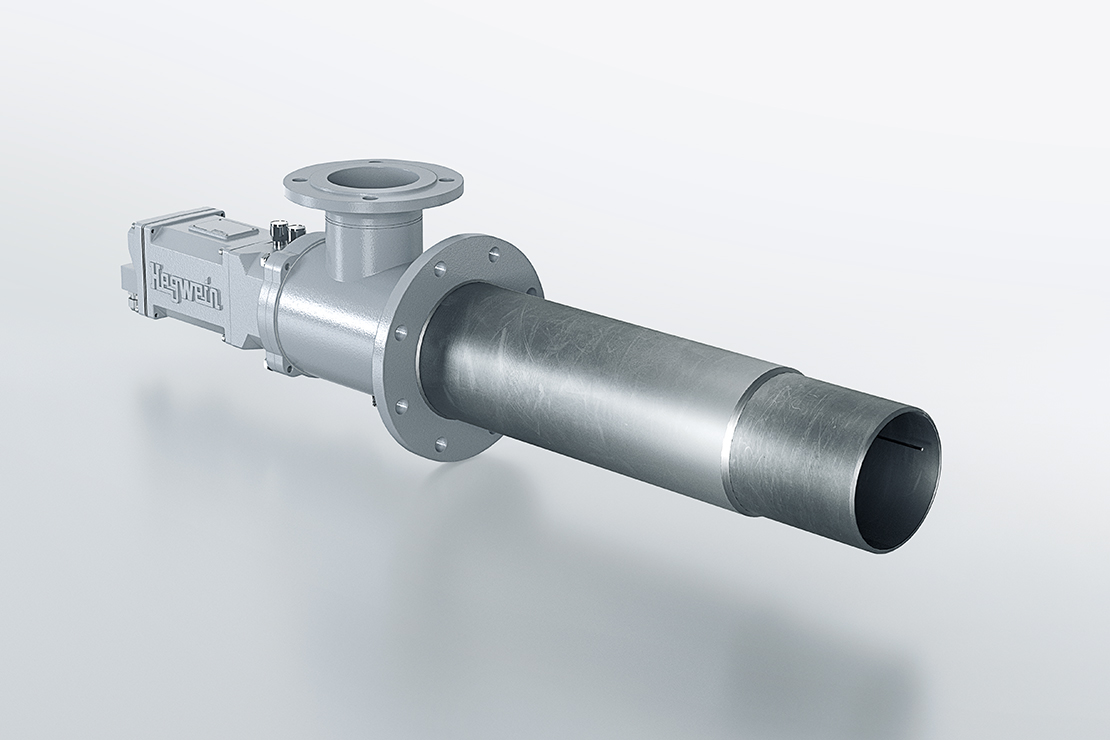

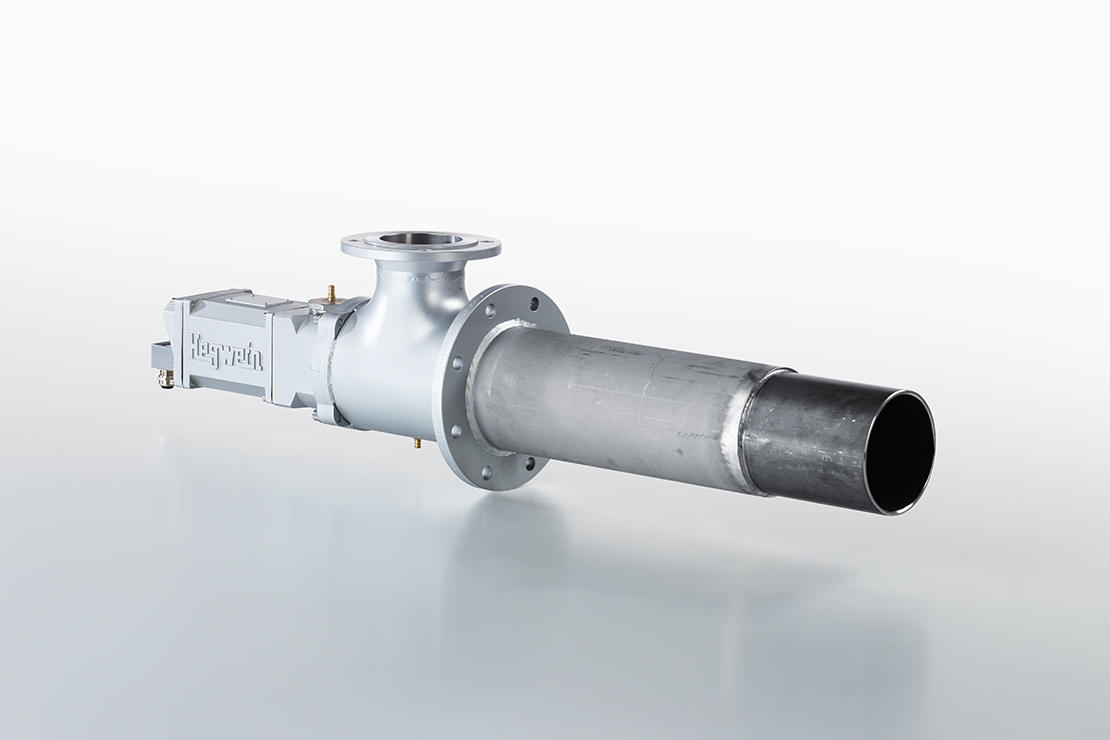

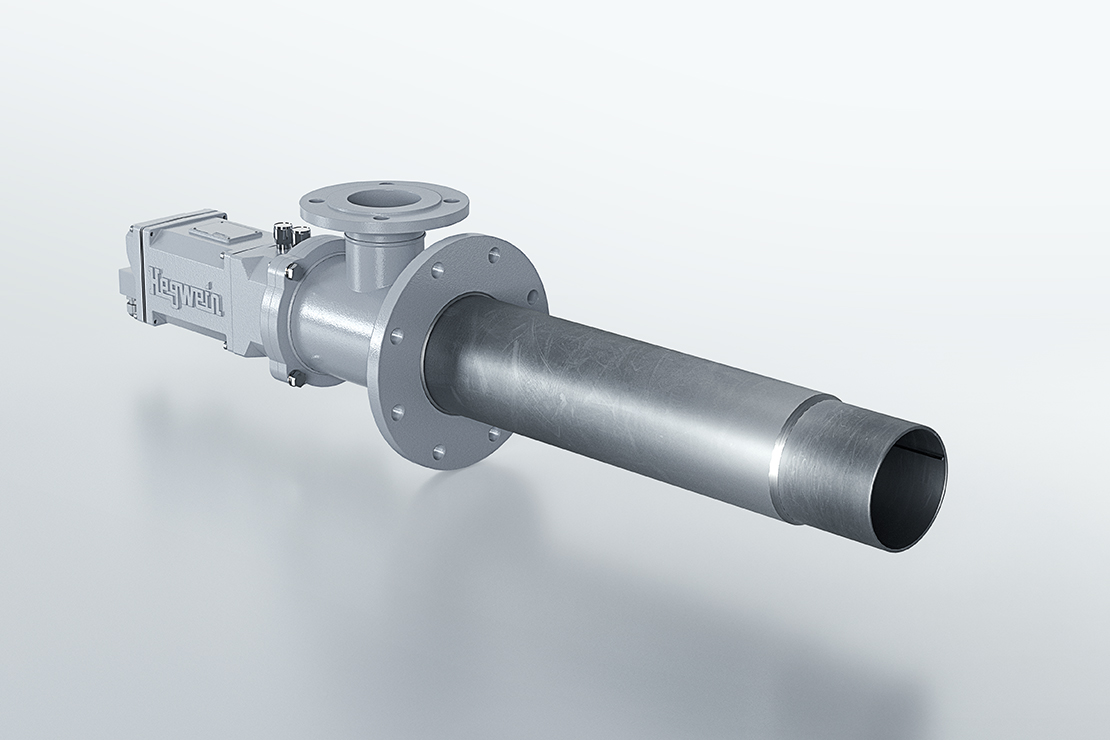

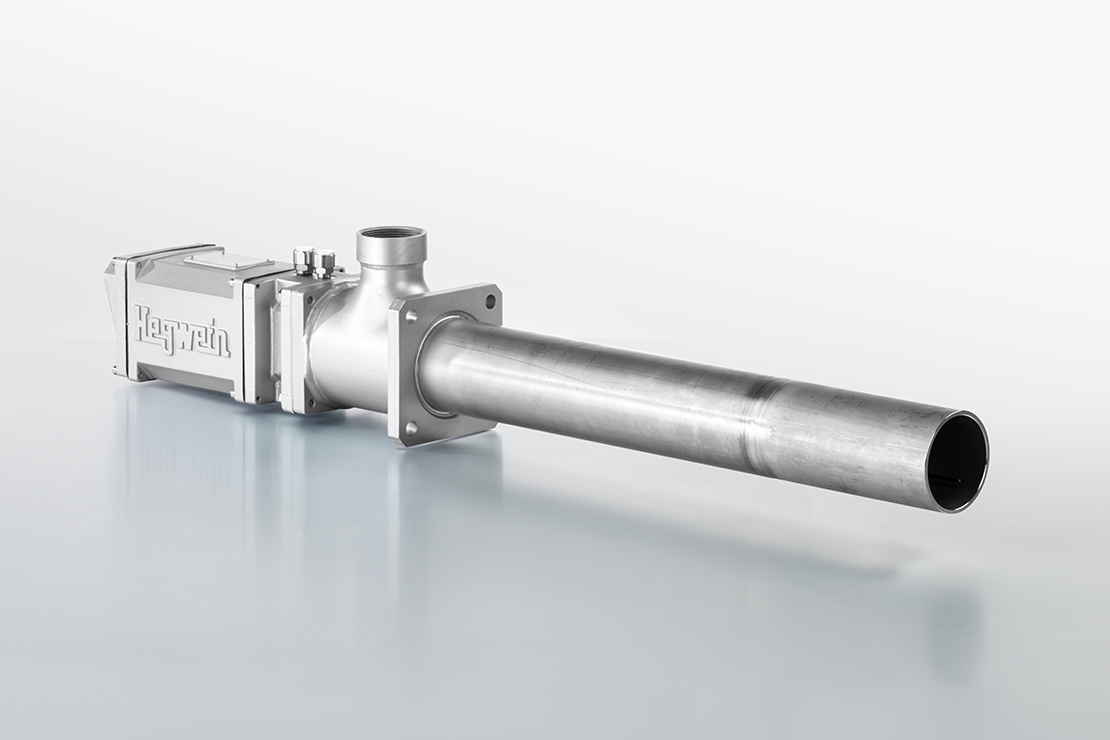

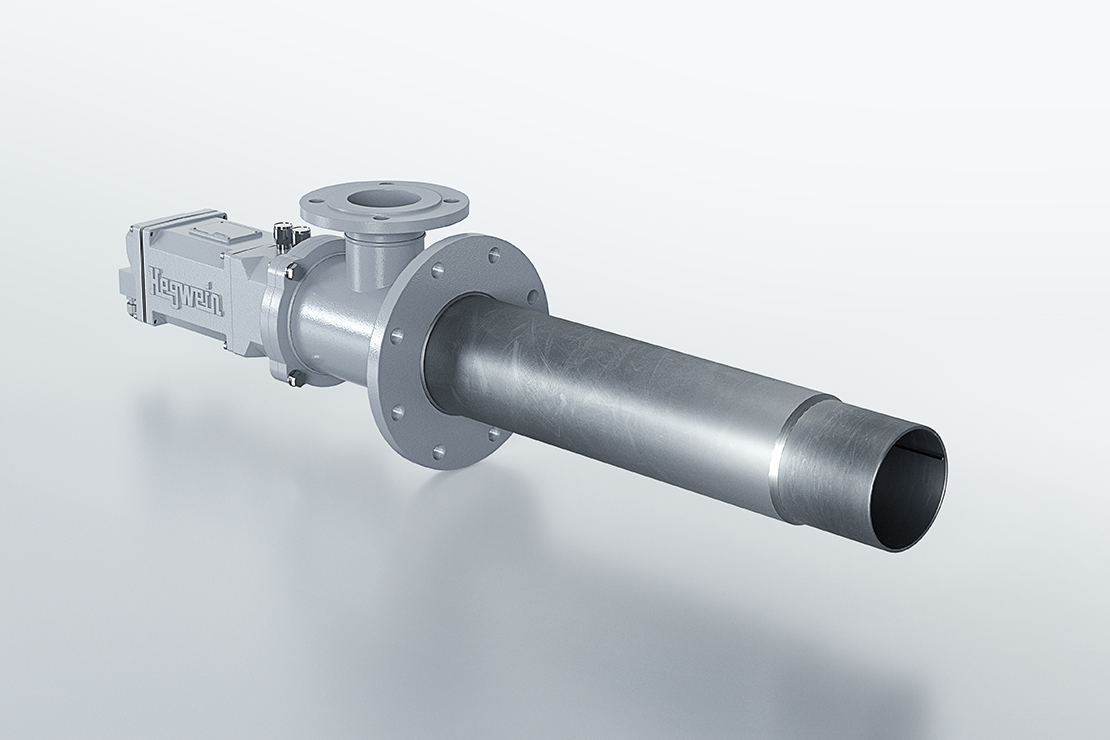

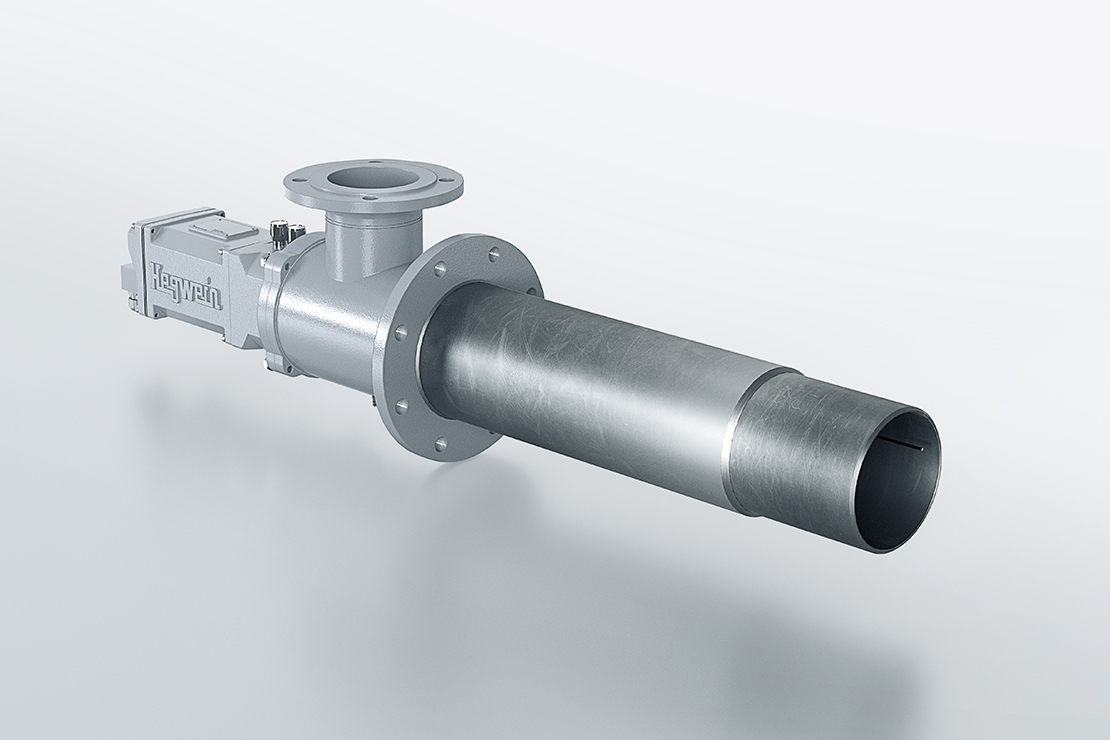

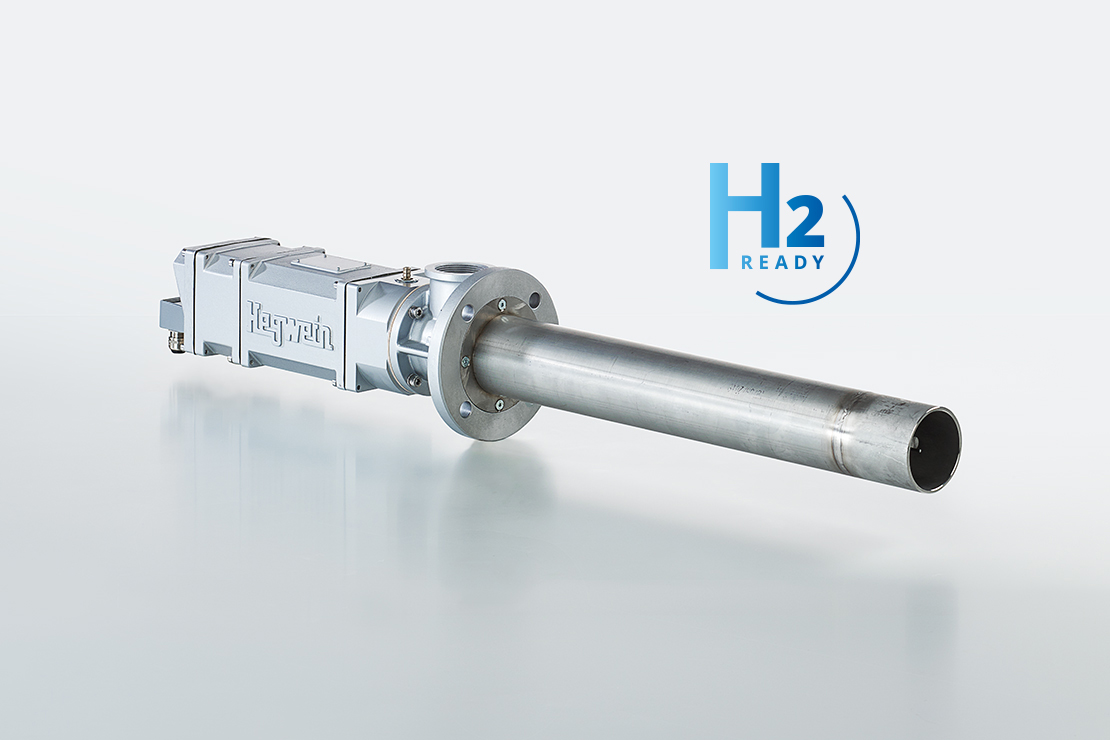

HEGWEIN oil ignition and pilot burner

Heat release 100 kW to 3.6 MW

Forced draft operated oil ignition and pilot burner with nozzle mixing device in compact, modular design for plant-specific solutions and fuel flexibility.

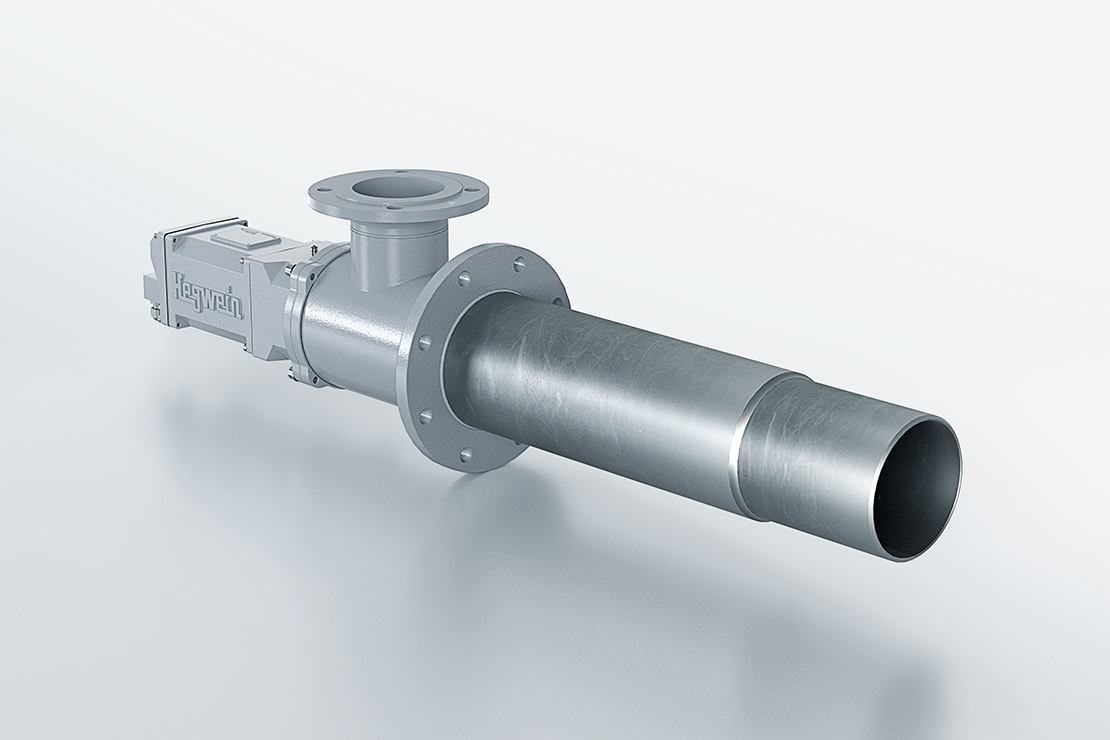

HEGWEIN gas burner

Heat release 15 kW to 4.5 MW

Gas burner solutions from HEGWEIN in compact and modular design. Meets local regulations, including hazardous area requirements.

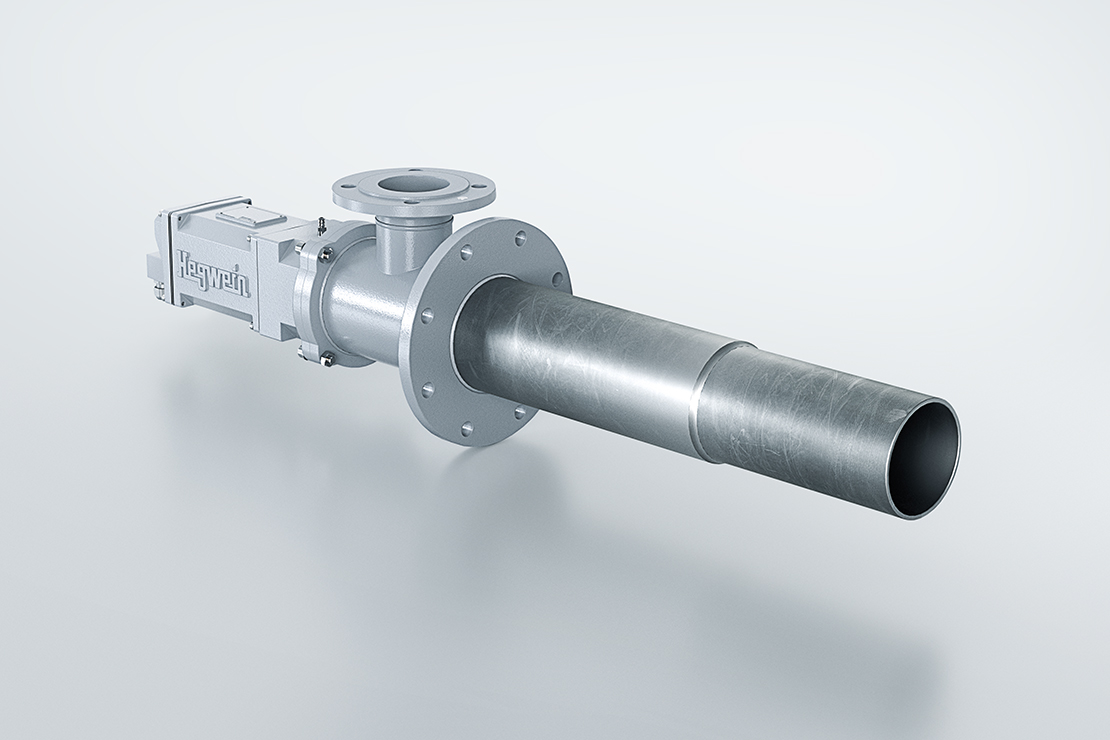

HEGWEIN oil burner

Heat release 150 kW to 6 MW

Oil burner with nozzle mixing device in compact, modular design for plant-specific solutions and fuel flexibility.

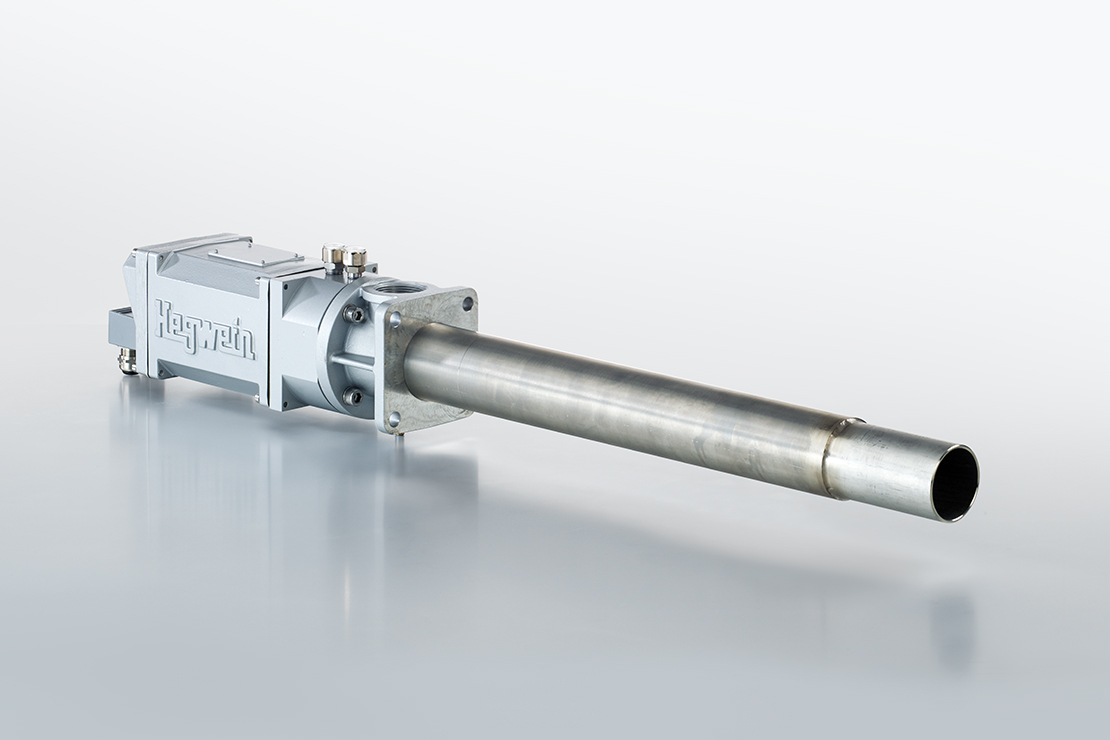

HEGWEIN gas ignition and pilot burner

Heat release 2 kW to 10 MW

Forced draft operated gas ignition and pilot burner up to a thermal capacity of 10 MW* with nozzle mixing device in compact, modular design for plant-specific solutions and fuel flexibility.

D-AM 150

Display module and first-out annunciator

Module for displaying all statuses, program steps and error messages in plain text and for troubleshooting using first-out annunciation.

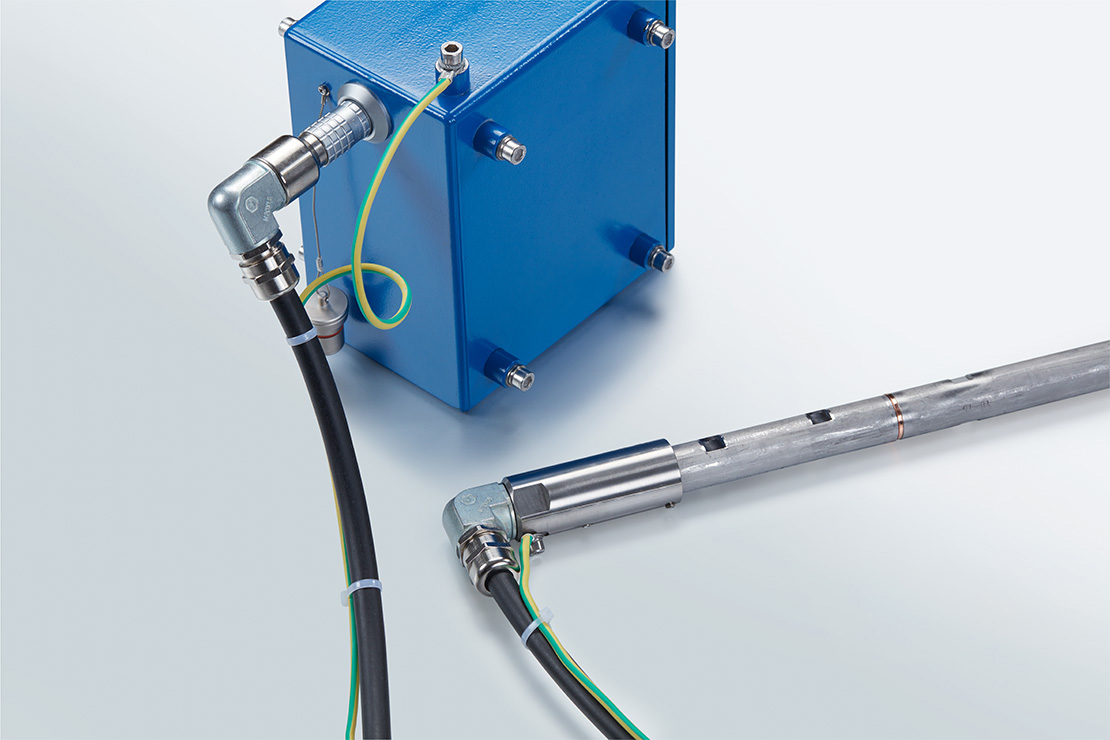

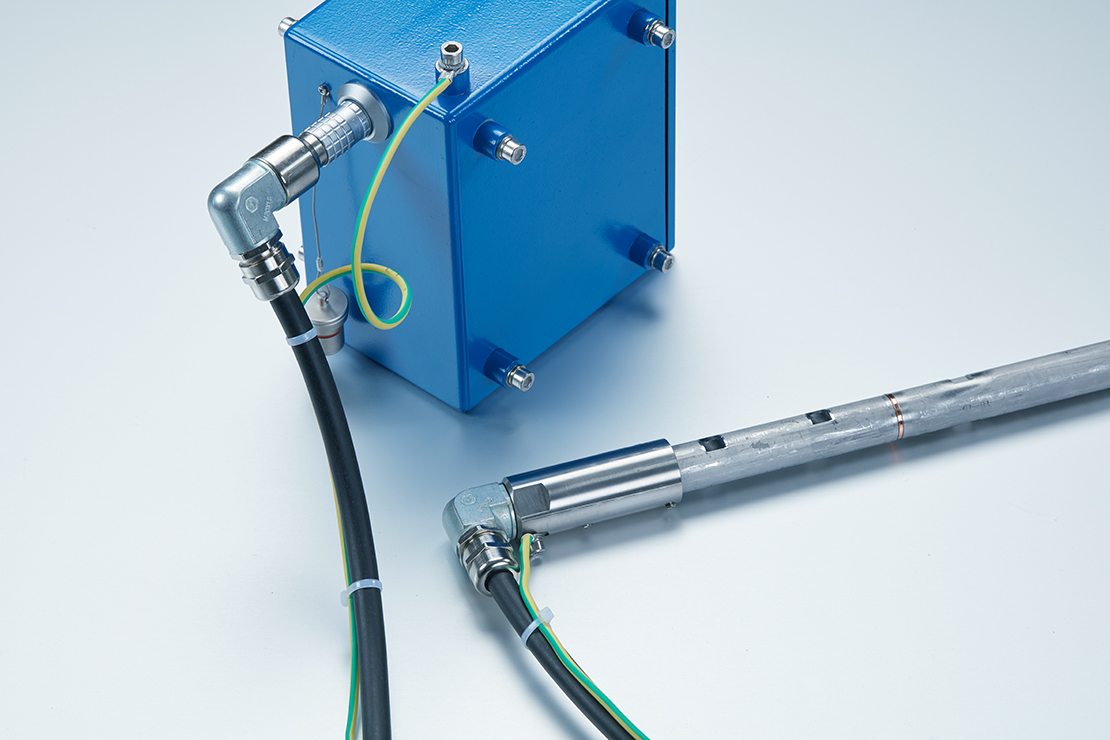

D-ZL 441Ex | D-ZL 430/31Ex | M22D

Ex ignition lances and high-voltage cables

Ignition lances and high-voltage cables for hazardous areas. Flexible lengths of ignition lances and cables for configuration of an Ex high energy ignition system for hazardous areas.

D-LL 7xx

Fibre optic systems

Fibre optic systems for combination with optical flame monitors. Transmission of electromagnetic radiation from the combustion chamber to the flame monitor when direct view is impossible or the connection conditions in place at the burner plate are particularly adverse.

FFG

Flame front ignition

Flame front generator for flare pilot burners. Ensures reliable ignition under all weather conditions. The flame front mixing chamber is ATEX and IECEx certified.

FFG60

Flare pilot burner

Self-aspirating pilot burner with flame front ignition. For flare ignition with heat release in accordance with API standard 537.

HD60

Flare pilot burner

Self-aspirating pilot burner for flare ignition with heat release in accordance with API standard 537. Standard with high energy ignition, optionally with flame front ignition.

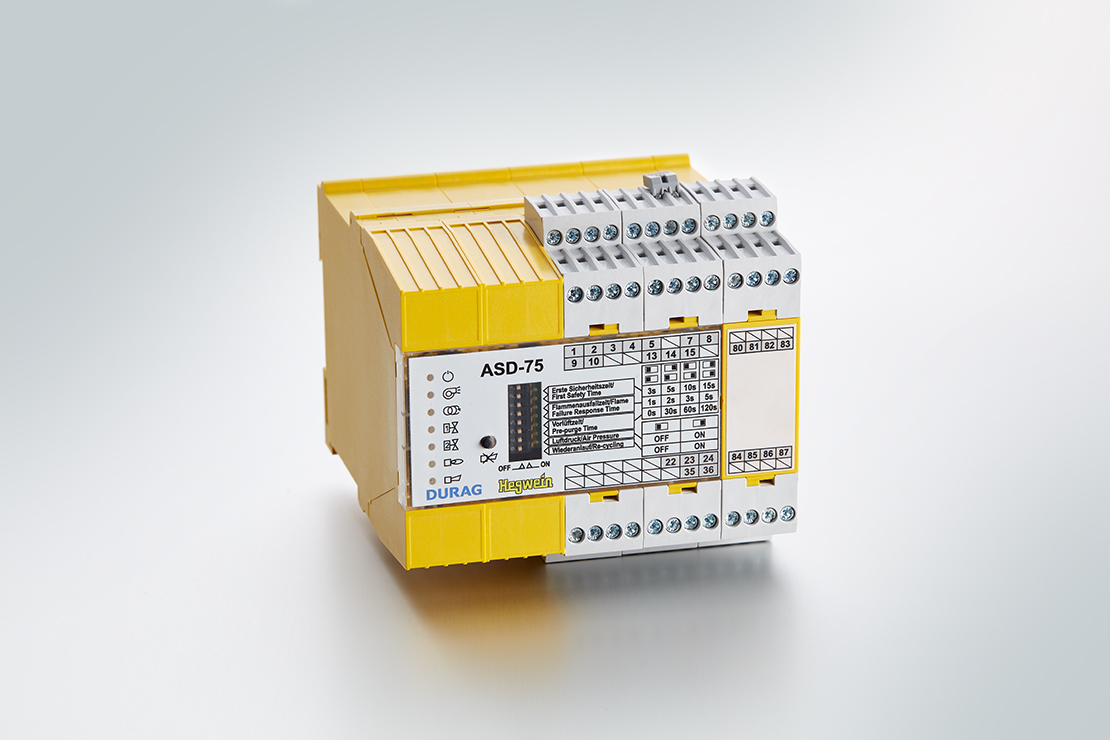

D-GF 75 | ASD-75

Burner controls

Self-monitoring and fail-safe burner controls for controlling simple gas burners with electric ignition.

D-UG 120

Control unit

Control unit for combination with optical flame sensors for monitoring gas, oil and coal flames. Particularly for applications with single burner view.

D-UG 660

Control unit

Control unit for high requirements, for combination with optical flame sensors. For monitoring gas, oil and coal flames, including in complex multi-burner plants.

.jpg)

D-GF 150(-MB)

Flexible burner control

Self-monitoring and fail-safe burner control for controlling gas and oil burners as well as combined gas/oil burners of any capacity. Variant “-MB” with integrated display and Modbus communication.

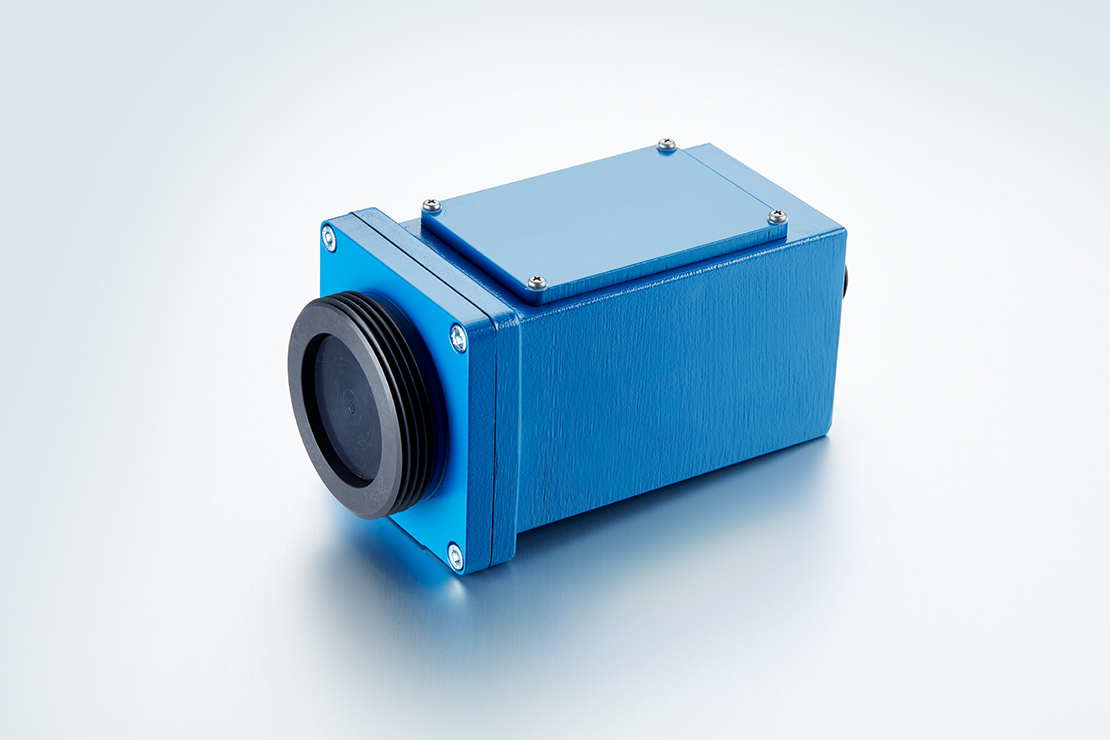

D-FS 50

Furnace camera

Compact furnace camera with air or water cooling for visualization of combustion chambers, combustion processes, flames and other hot processes.

D-FS2

Furnace camera

Furnace camera for extreme ambient conditions with air or water cooling for visualization of combustion chambers, combustion processes, flames and other hot processes.

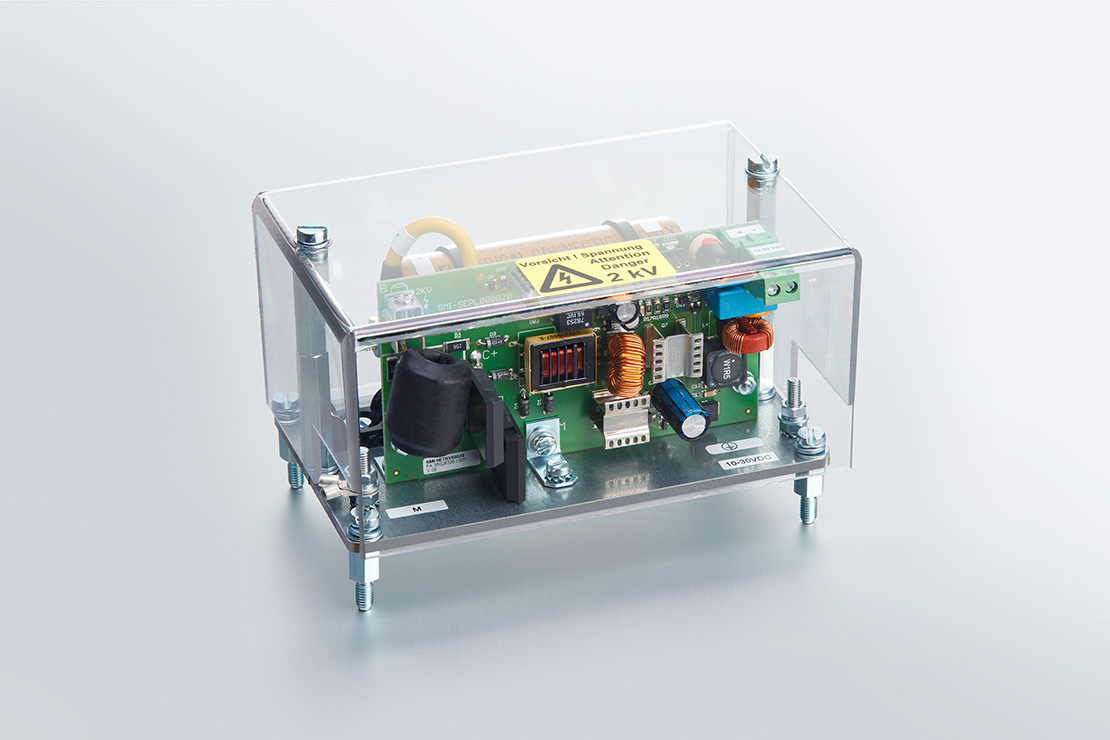

D-HG 400

Heat release 2 kW to 10 MW

High energy ignition device with 90 J/s for direct and reliable ignition of gas and liquid fuels.

D-HG 500

High energy ignition device

High energy ignition device with max. 112 J/s for direct and reliable ignition of gas and liquid fuels. The ignition frequency and duration are variable.

E-LIGHT

High energy ignition unit

Powerful and reliable solution for the ignition of gaseous fuels and light fuel oil. Ignition energy of 2 joules per spark.

E-SPARK

High energy ignition unit

Powerful and reliable solution for the ignition of gaseous fuels and light fuel oil. Spark energy of 4, 8 or 12 joules/spark.

D-LX 110/710

Optical compact flame monitor

Easy, versatile and flexible compact flame monitor with integrated UV, VIS or IR flame sensor for monitoring gas, oil and coal flames. Particularly for applications with single burner view.

D-LX 101/701

Optical compact flame monitor for single burner flames

Easy, versatile and flexible compact flame monitor with integrated UV or IR flame sensor for monitoring gas, oil and coal flames. Particularly for applications with single burner view.

D-GT 800

Optical flame sensor

UV flame sensor for monitoring gas, oil and coal flames under particularly harsh conditions. Particularly at gas turbines or in environments with high temperature, high connection pressure or strong vibrations.

D-LE 603/703

Optical flame sensor

UV, VIS or IR flame sensor for combination with a control unit or automatic burner control. For optical monitoring of all fuel flames, including in complex multi-burner plants.

D-LE 701

Optical flame sensor

UV, VIS or IR flame sensor for combination with fibre optic systems and a control unit or burner control. For optical monitoring of all fuel flames, including in complex multi-burner plants.

FD

Pressure monitor

Flexible and highly robust pressure monitor for safe and reliable monitoring of pressure limits.

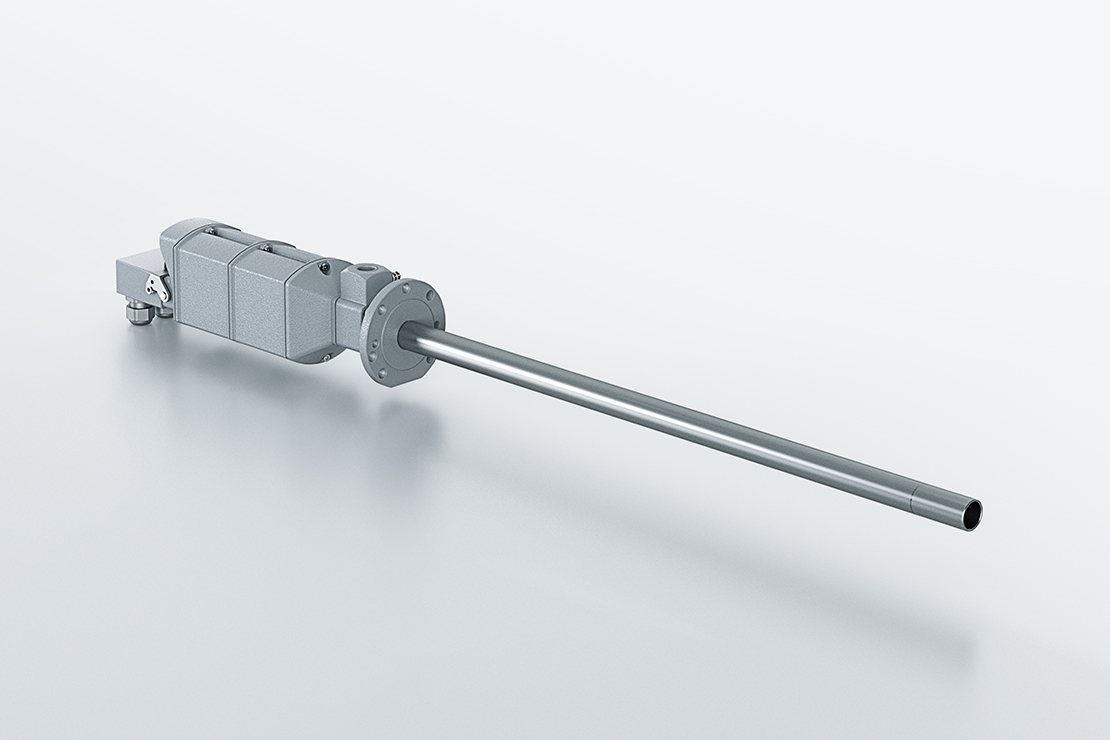

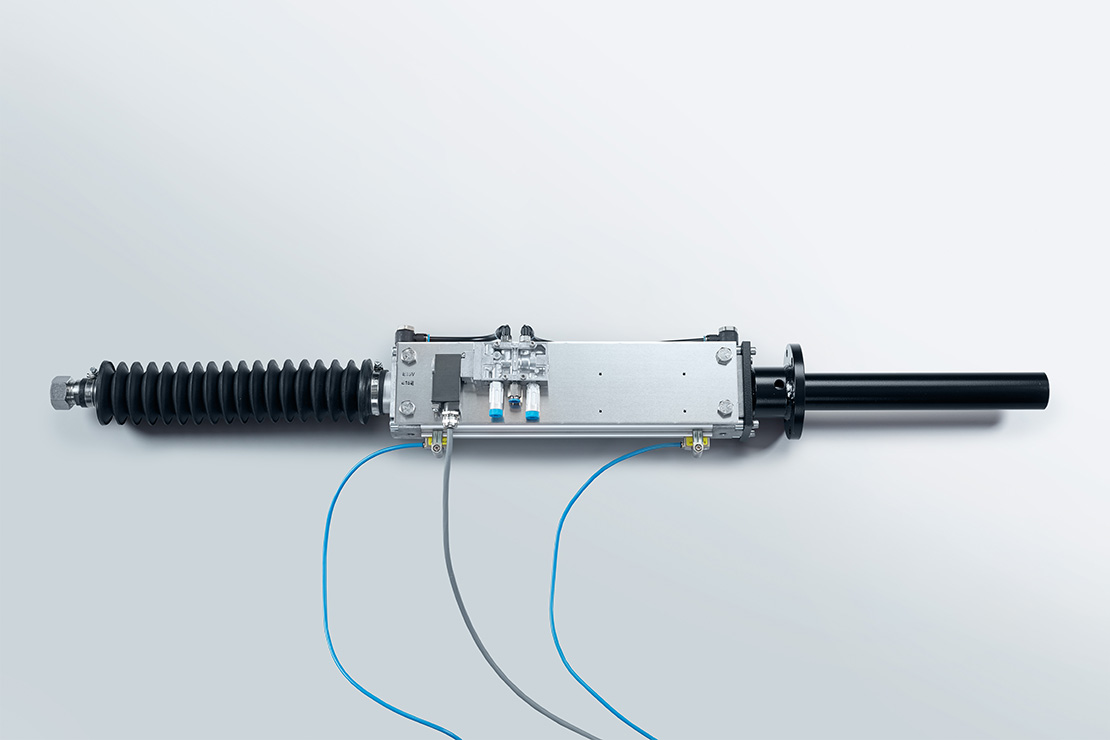

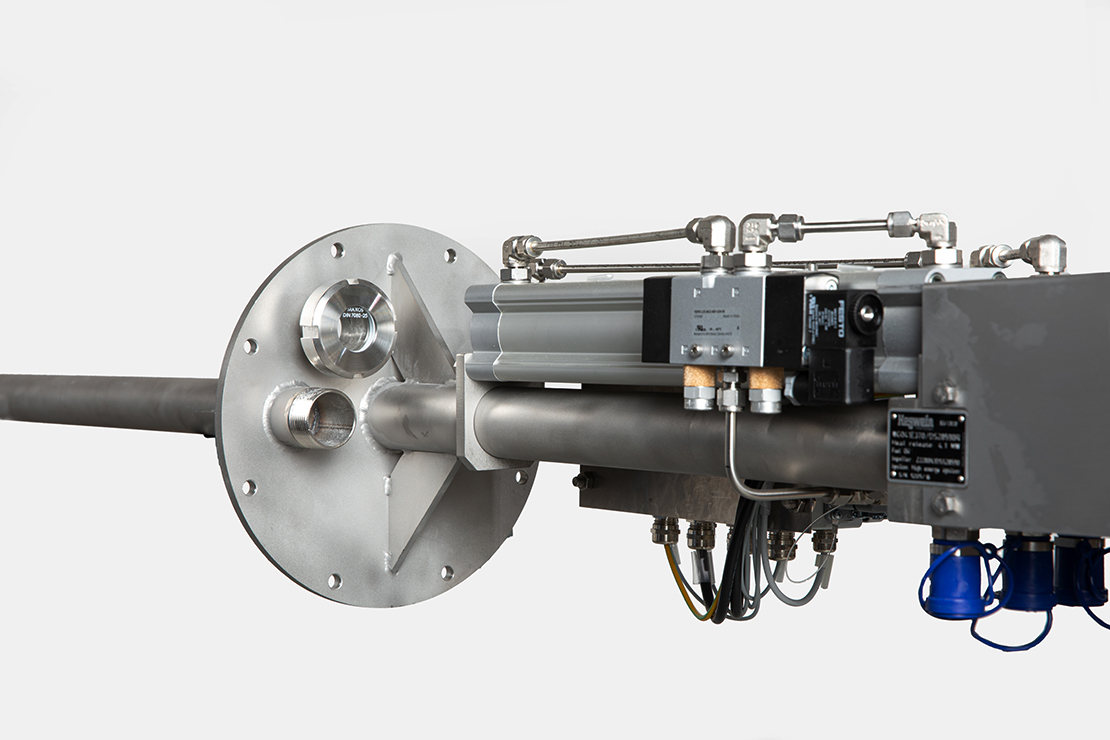

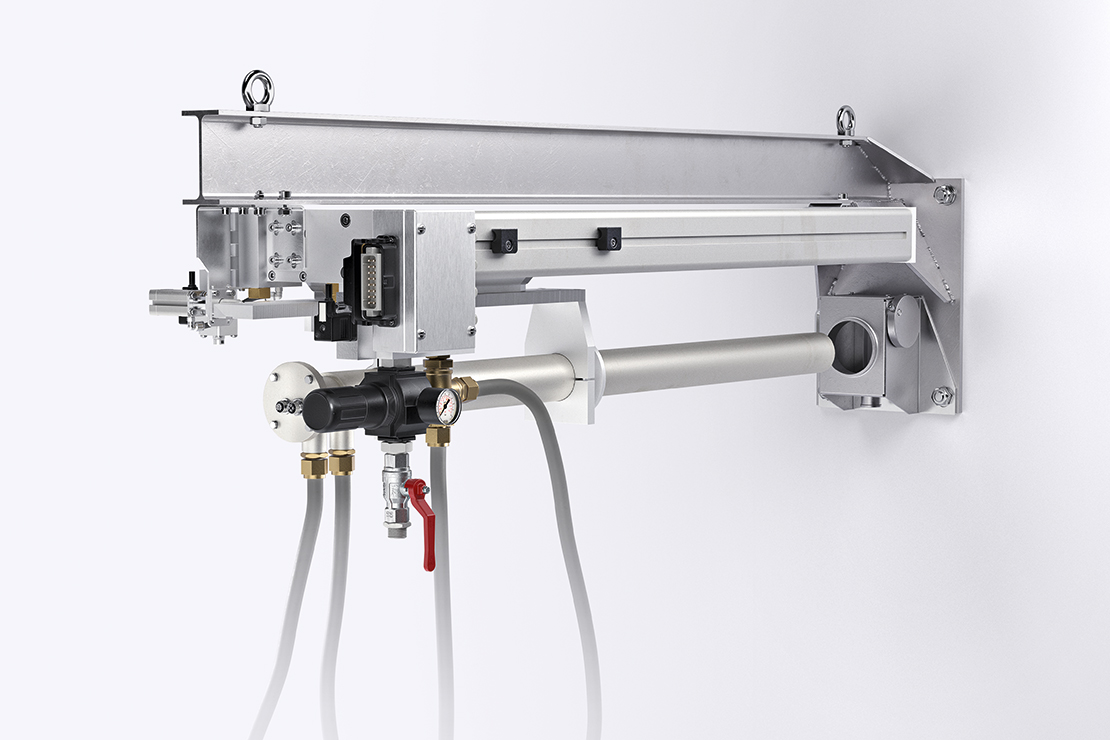

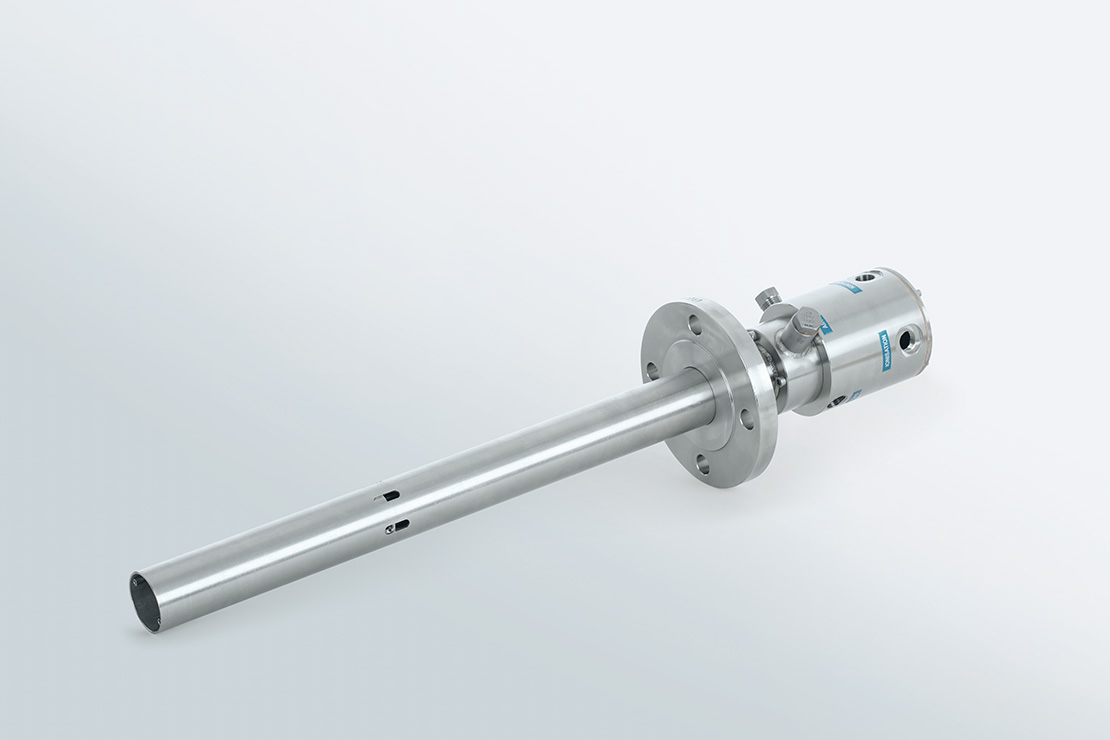

D-RU | D-SCU

Retraction unit

Pneumatic retraction unit for safe retraction and extension of the furnace camera as required and automatically in the event of a cooling failure. Used in conjunction with the sensor control unit, the D-RU offers maximum protection of the furnace camera.

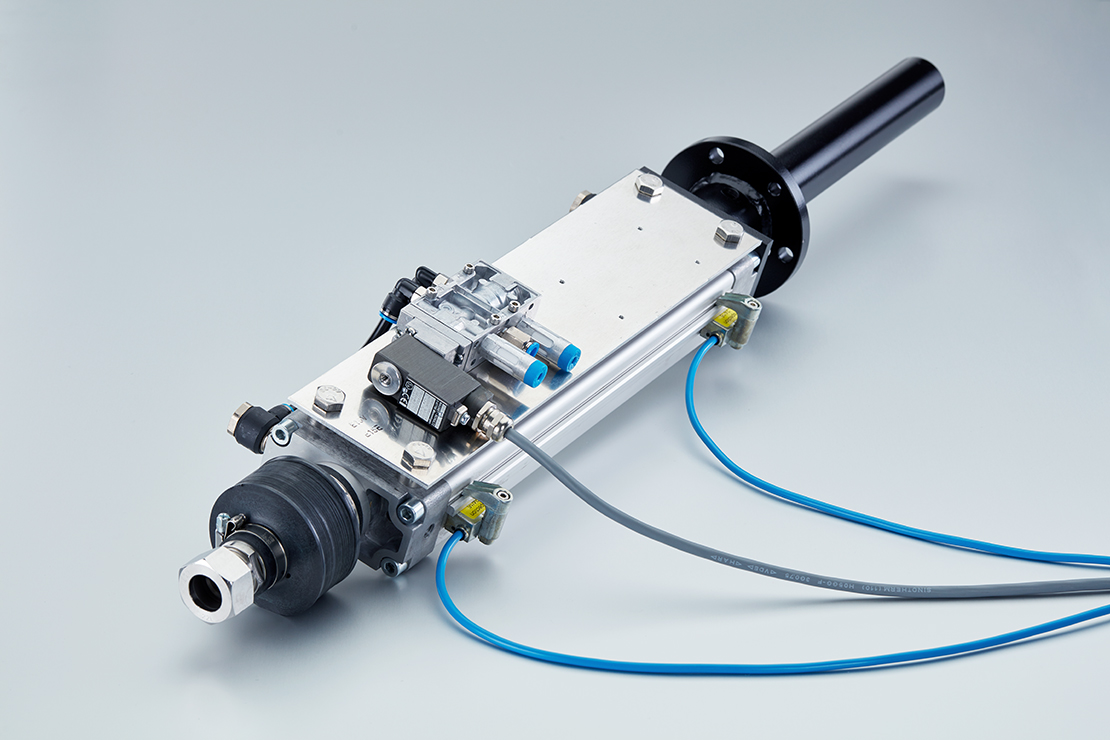

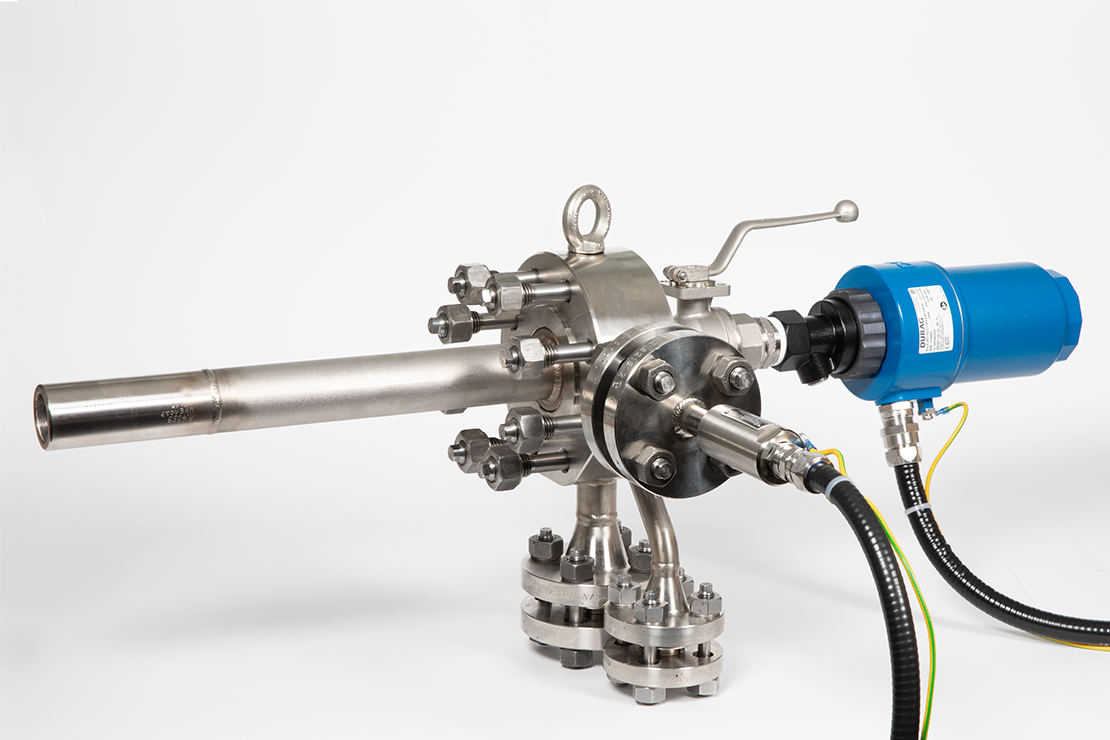

D-VE 500

Retraction unit

Pneumatic retraction unit for safe retraction and extension of the ignition lance before and after successful ignition. Used to prevent excessive temperatures and wear at the ignition tip, helping to reduce costs for spare parts

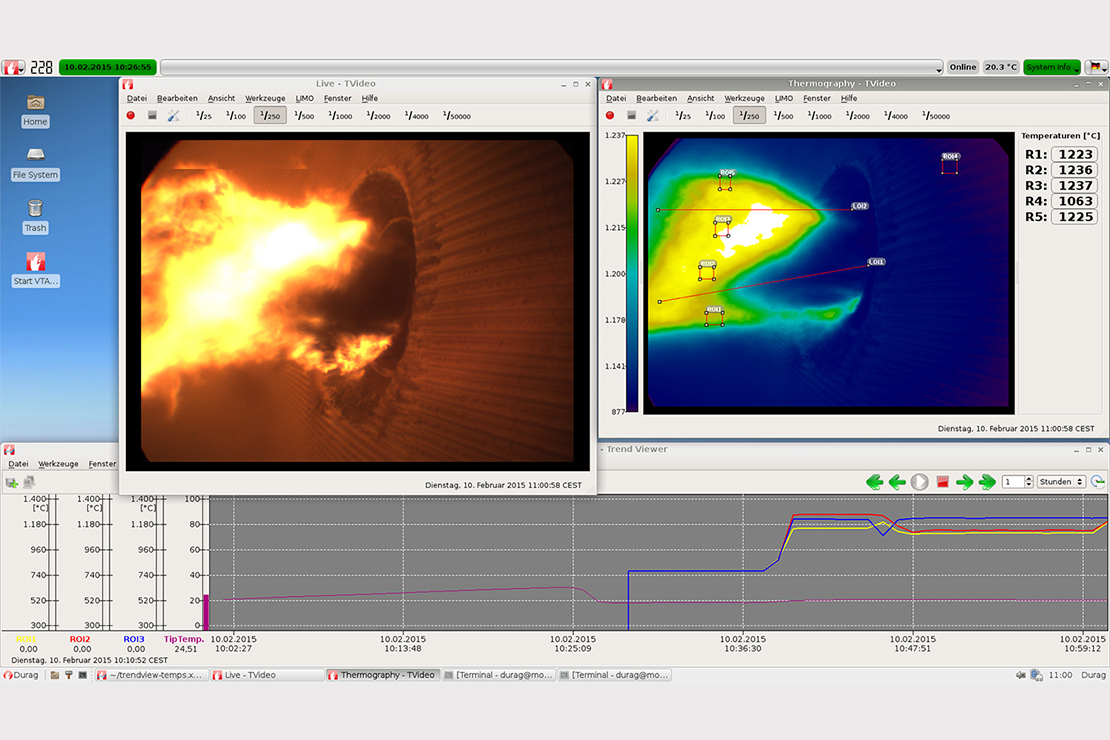

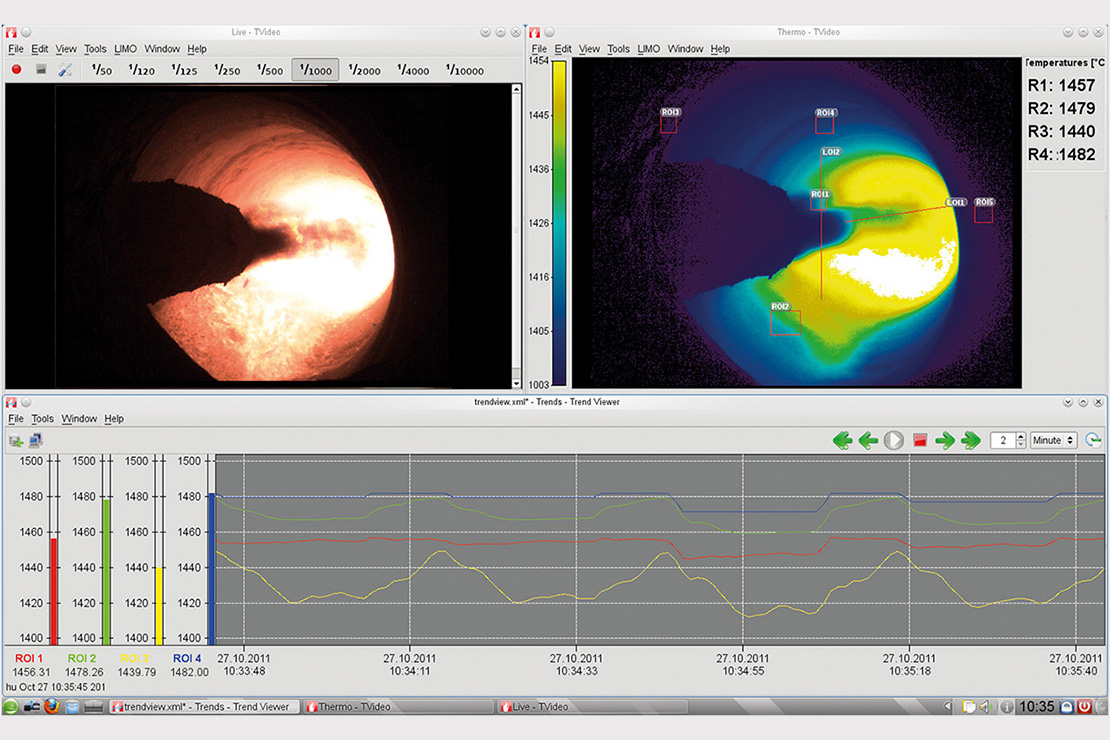

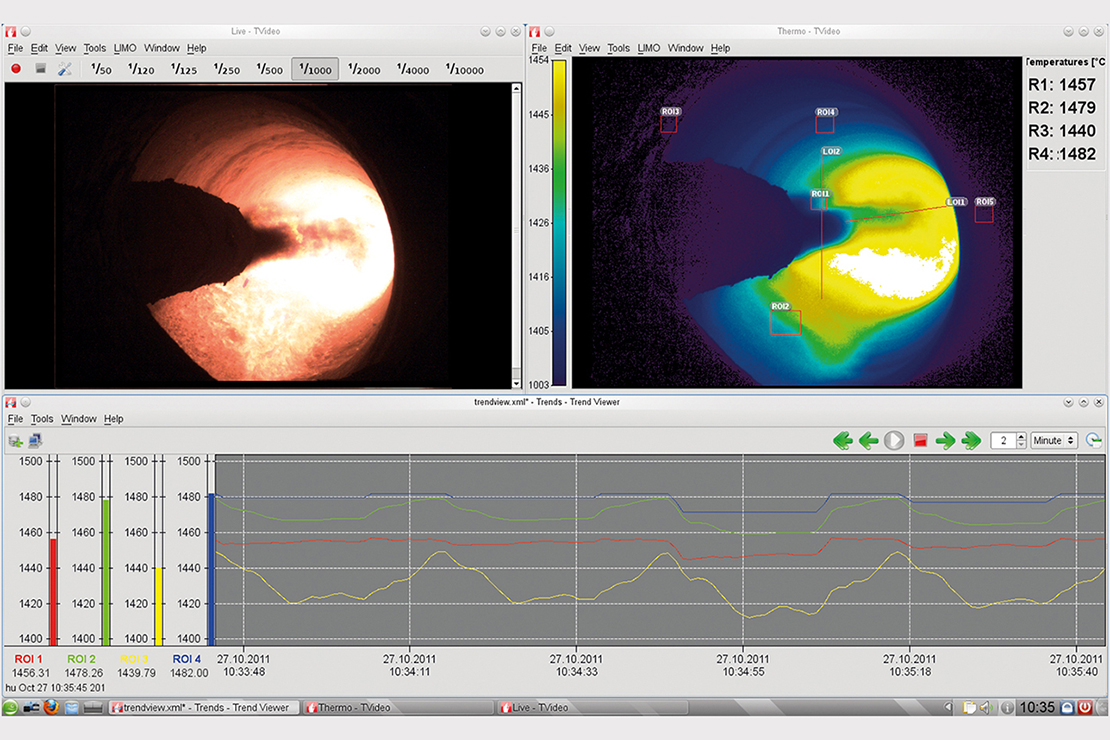

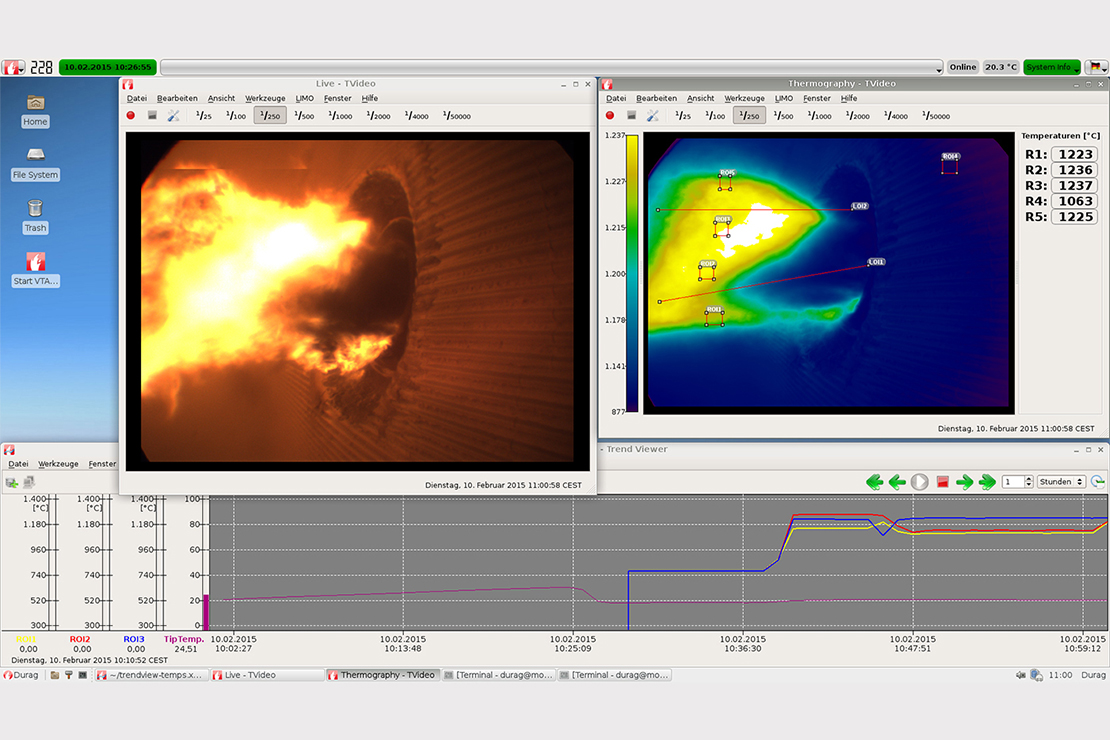

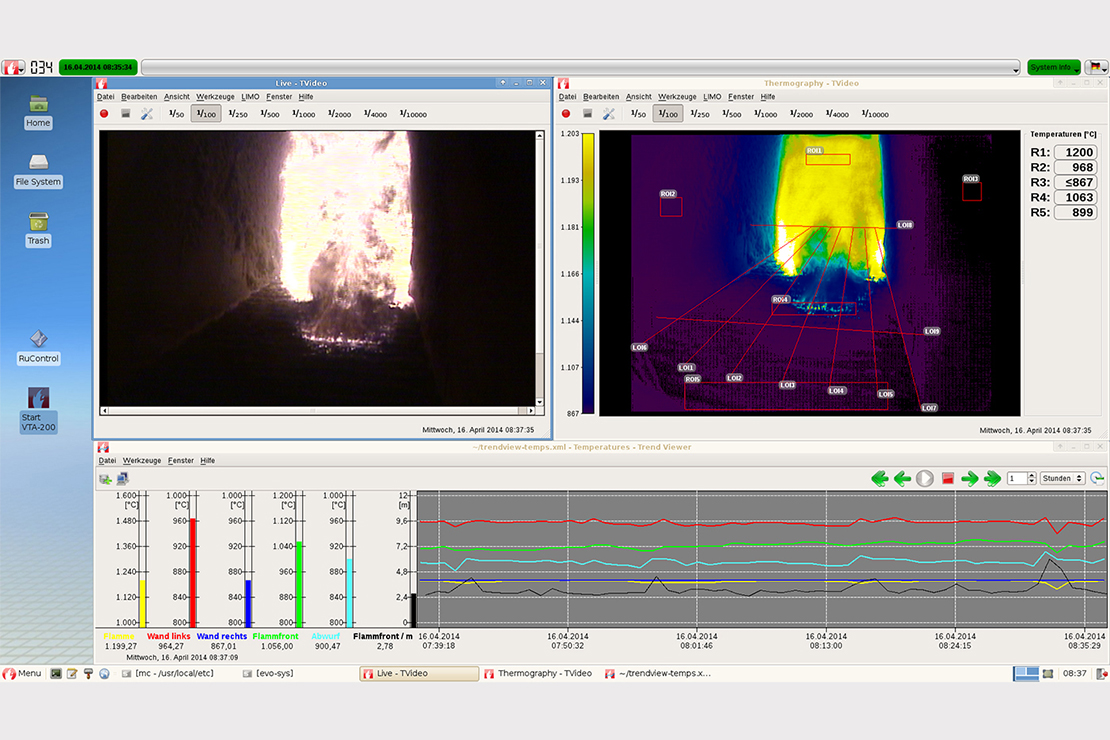

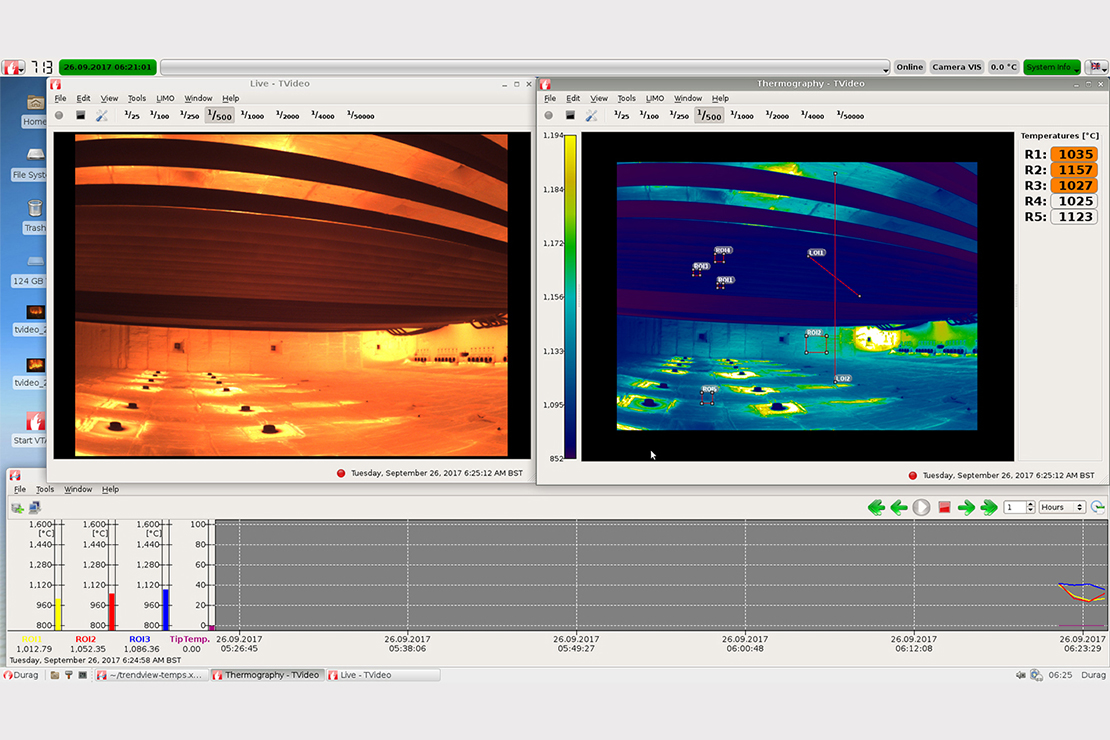

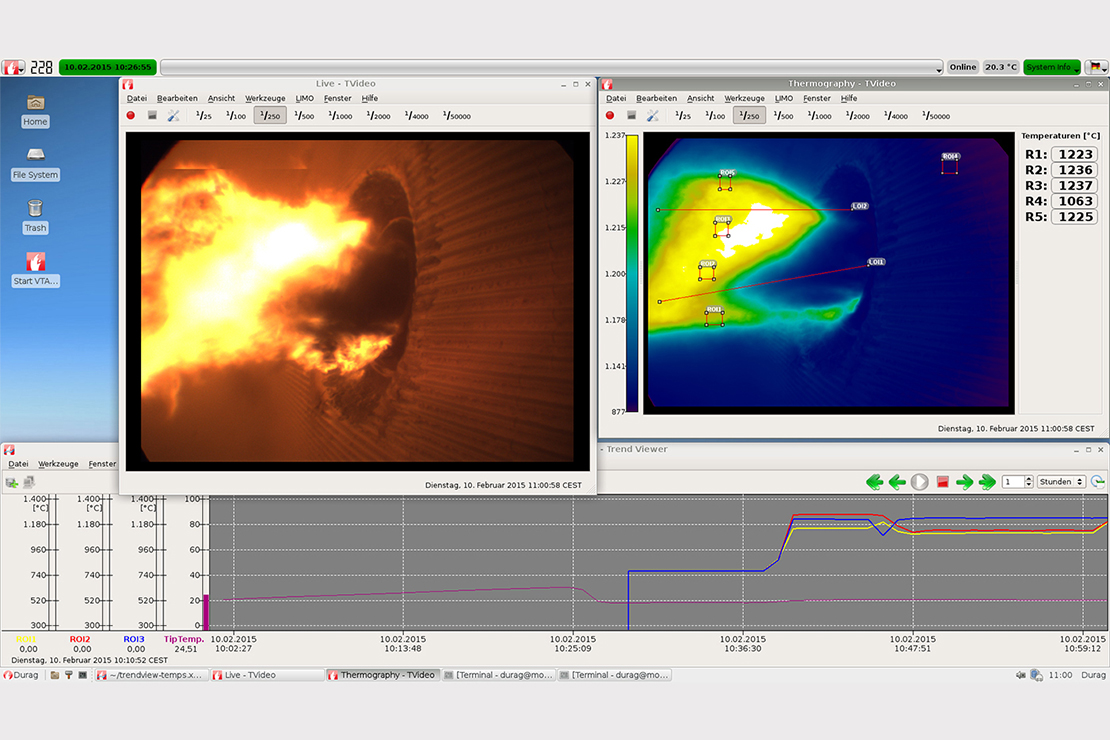

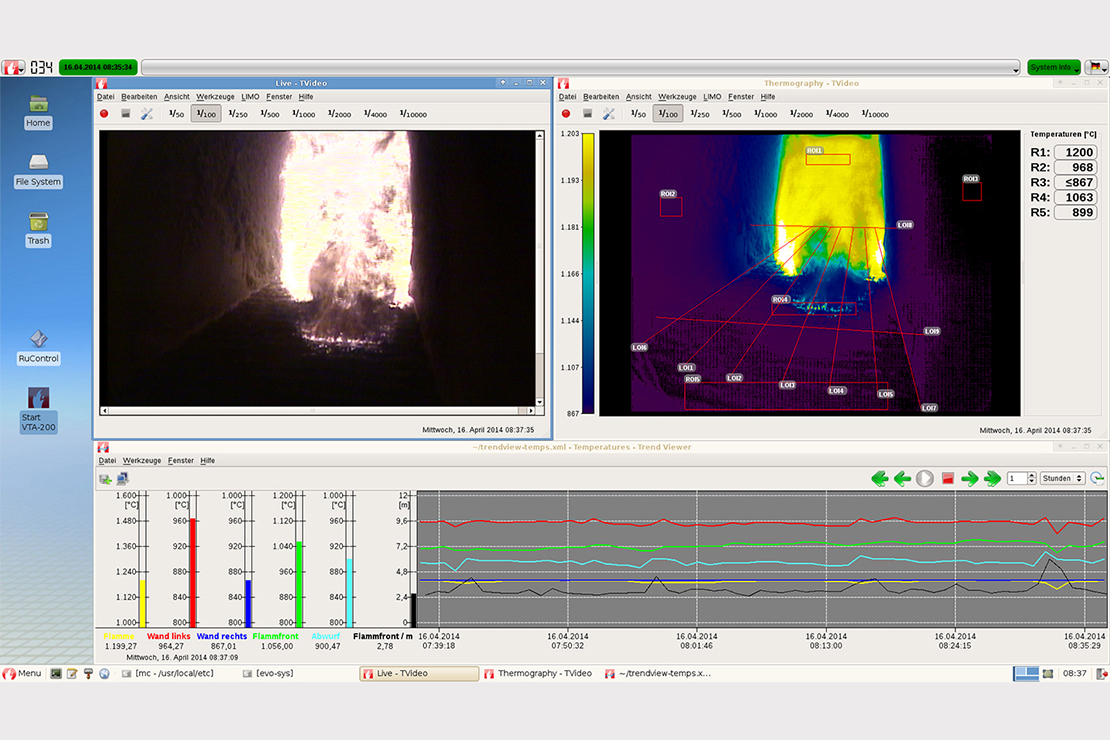

D-VTA 200

Video and thermography software

Video and thermography software for displaying live video and the calculated temperature distribution from one or more combustion chamber cameras. Includes long-term data storage, video recording, configurable trend displays, offers digital interfaces to process control systems and can be expanded with additional modules.

D-VTA 200 for the cement industry

Video and thermography system

Video and thermography system for the cement industry for monitoring of the sintering process in the rotary kiln and the processes in the clinker cooler. Provides clinker and flame temperatures from the rotary kiln and shows “red river” and “snowman” in the clinker cooler. Used to improve clinker quality and optimize substitute fuels, helping to reduce fuel costs.

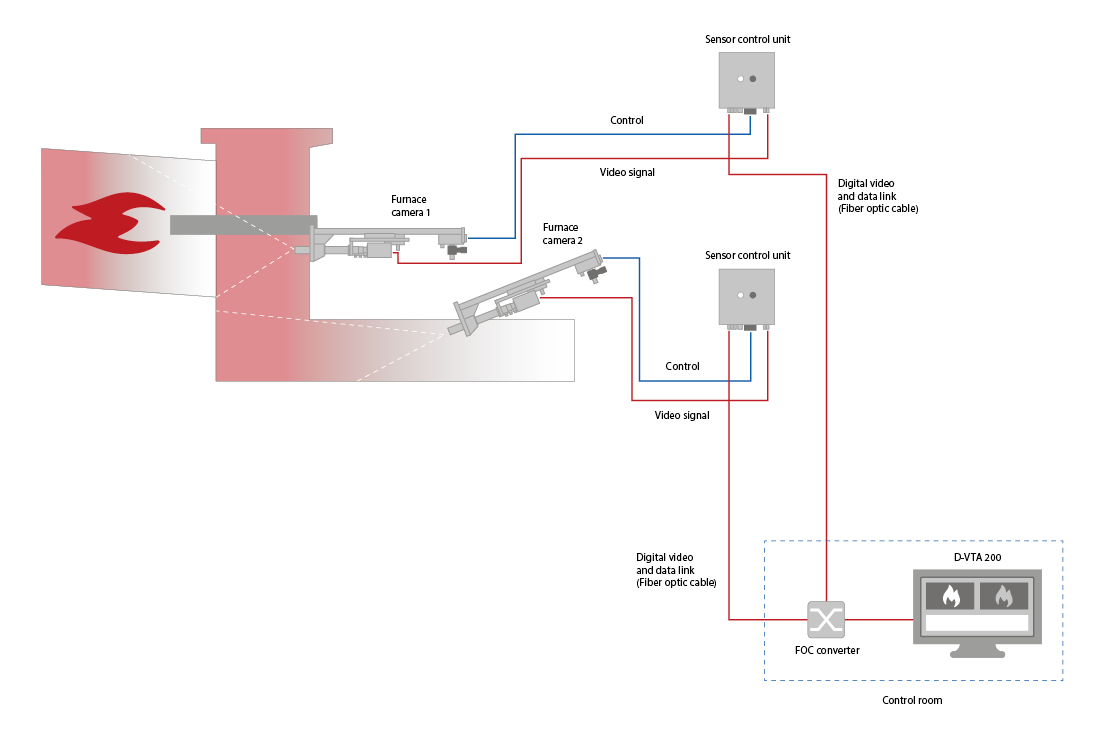

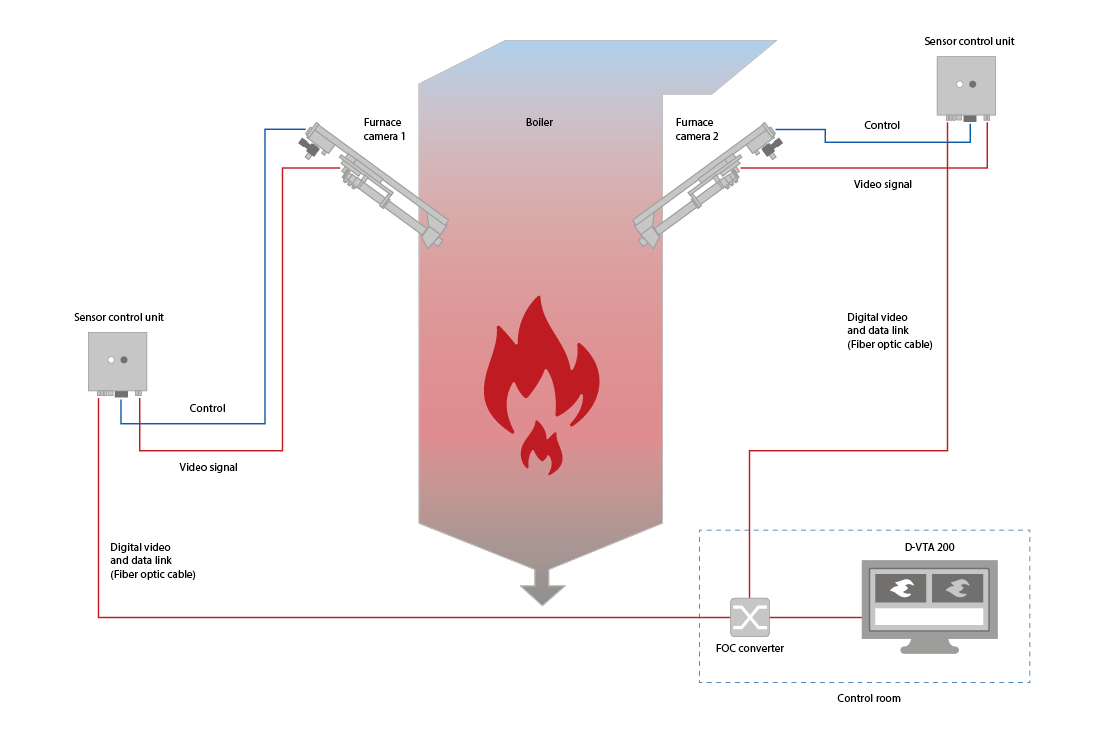

D-VTA 200 for fossil fuels

Video and thermography system

Video and thermography system for fossil fuels. Provides live images and temperature distribution from power plant boilers. Helps save fuel costs and avoid tube ruptures, reducing costs and downtime. Used to monitor the burners in the start-up process, to monitor the fireball and to support fuel and load changes.

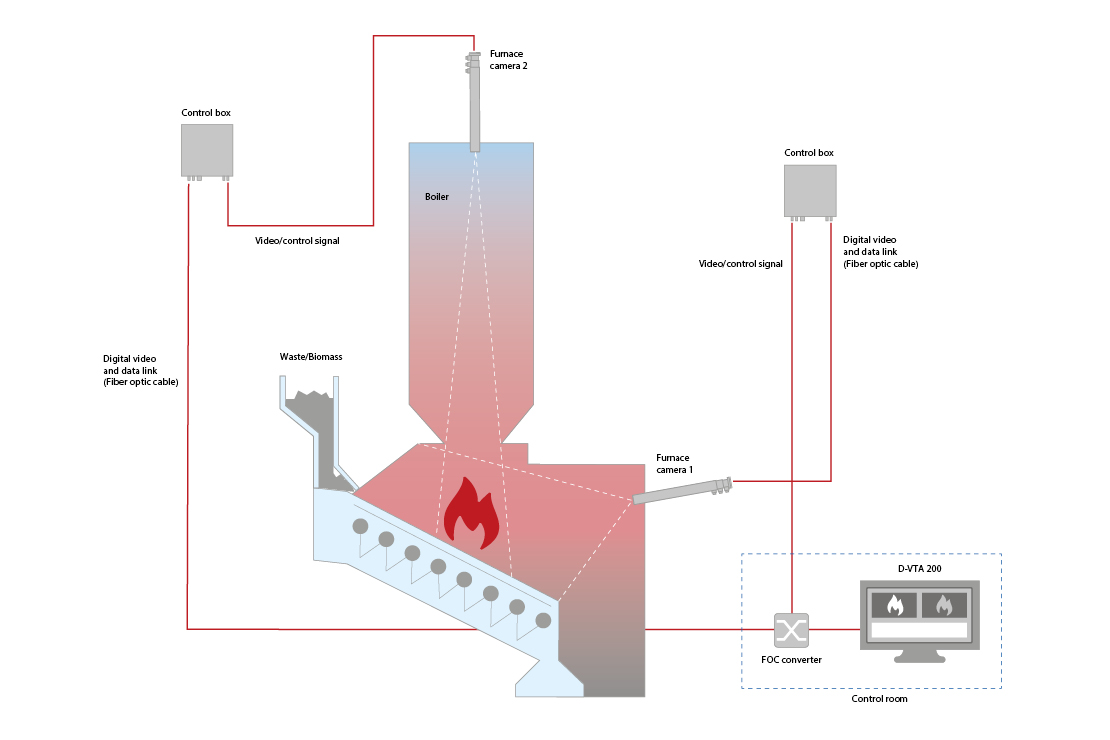

D-VTA 200 for grate firing

Video and thermography system

Video and thermography system for grate fired furnaces for monitoring the out burning zone on the grate. Used for automated combustion control and to optimize SNCR injection, saving costs and reducing wear.

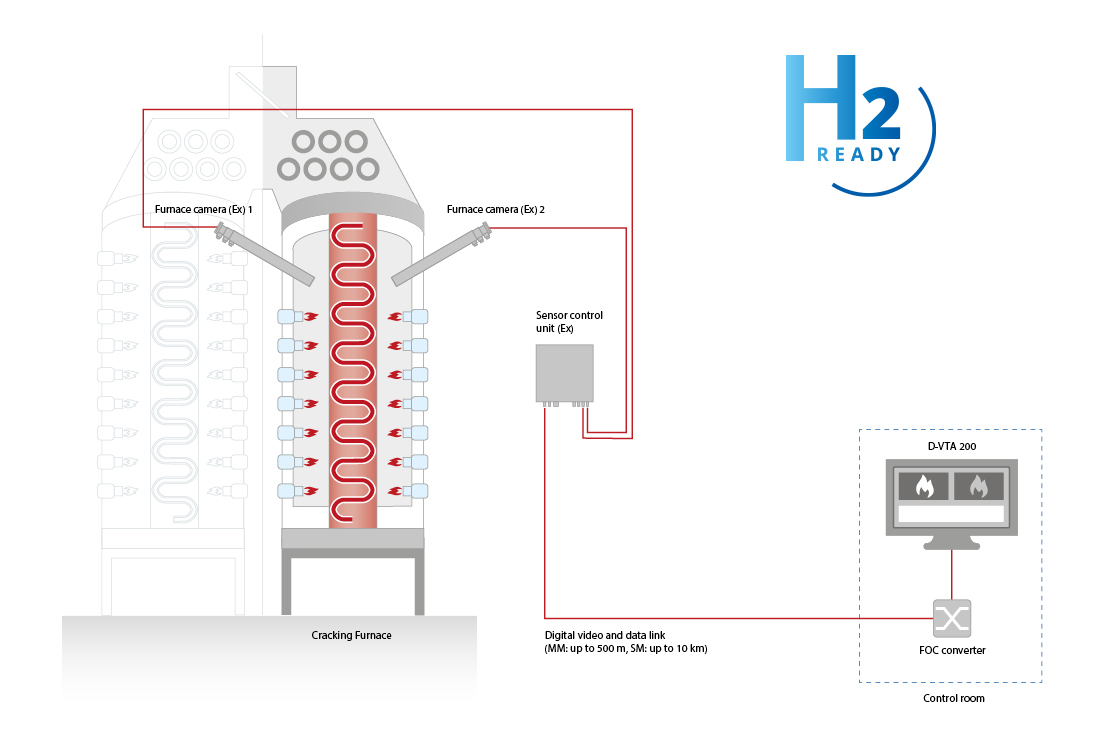

D-VTA 200 for cracking furnaces

Video and thermography system

Video and thermography systems for cracking furnaces are used in the petrochemical industry to monitor the furnace interior and production tubes. Special combustion chamber cameras are used for hazardous areas. The systems help to detect burner anomalies and combustion imbalances, reducing the risk of tube ruptures and unnecessary shutdowns.

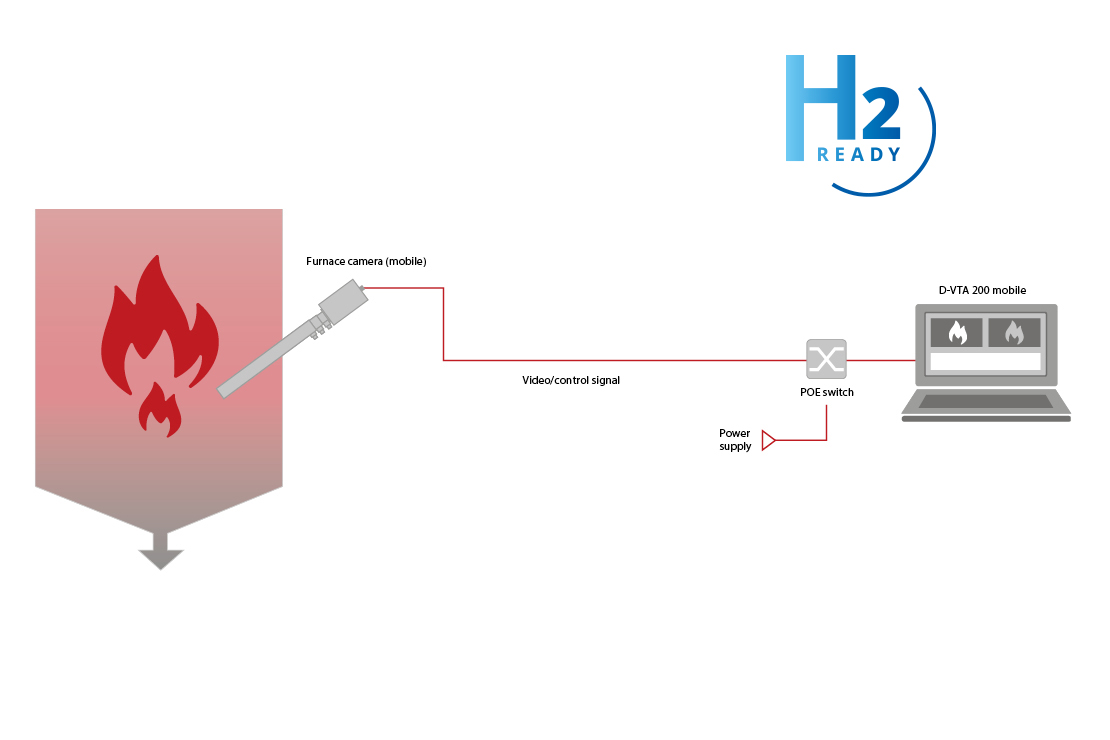

D-VTA 200 Mobile

Video and thermography system

Mobile, flexible video, thermography and analysis system for inspecting and documenting industrial high temperature processes and combustion systems. For combination with a digital combustion chamber camera.

Wheeled ignition system

Self-aspirating, wheeled high energy ignition burner with gas control, hose and lorry.

Self-aspirating gas ignition and pilot burner

Self-aspirating 38, 48 or 54 mm gas igniter for reliable ignition of a main burner.

High energy spark plug

Spark plug resistant to high temperatures. Diameter, length and connection are offered according to customer requirements.

Customized solutions

Some applications require ignition and burner systems whose dimensions, performance, technology or other specifications differ from our usual standards.

HEGWEIN microwave plasma igniter

Fuel-free ignition system with plasma beam (ionized gas volume) and high ignition potential.

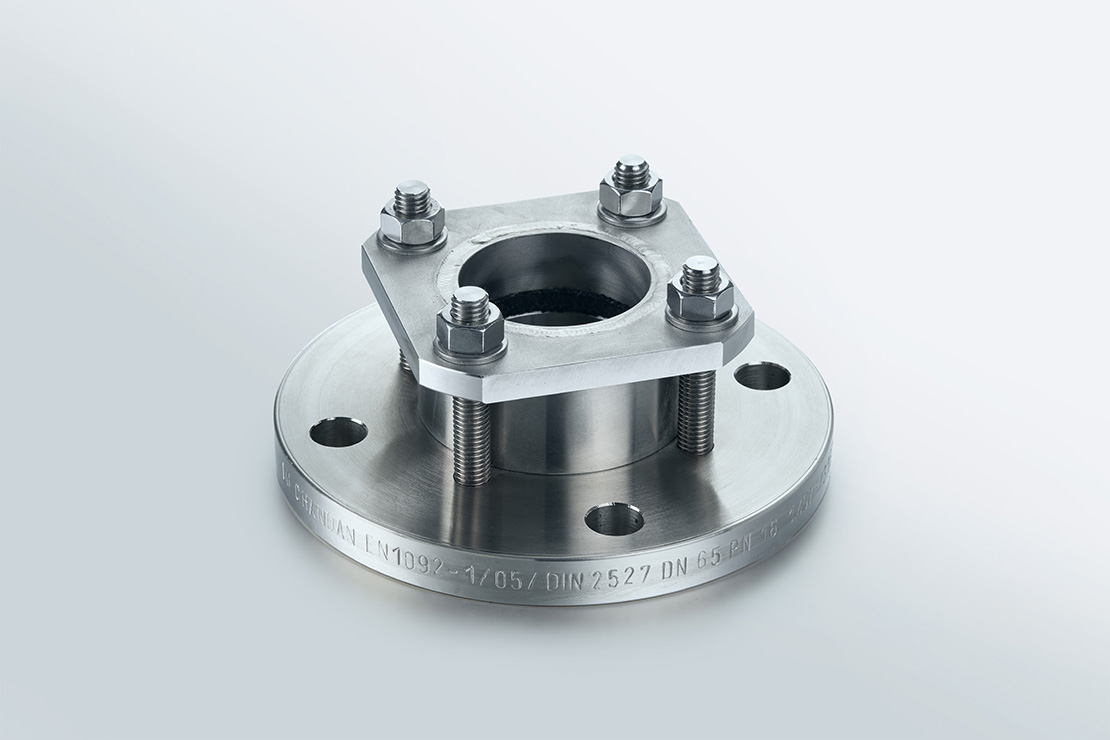

D-FS accessories

Accessories for furnace cameras and video and thermography systems. Here you will find accessories such as welding plates and flanges for easy installation, fiber optic cables for connecting the field and control room, cables for the furnace camera and retraction unit, and FOC Ethernet converters.

Accessories for flame monitors and burner controls

For mechanical connection, optical adjustment, electrical connection and function tests in particular of optical flame monitors.

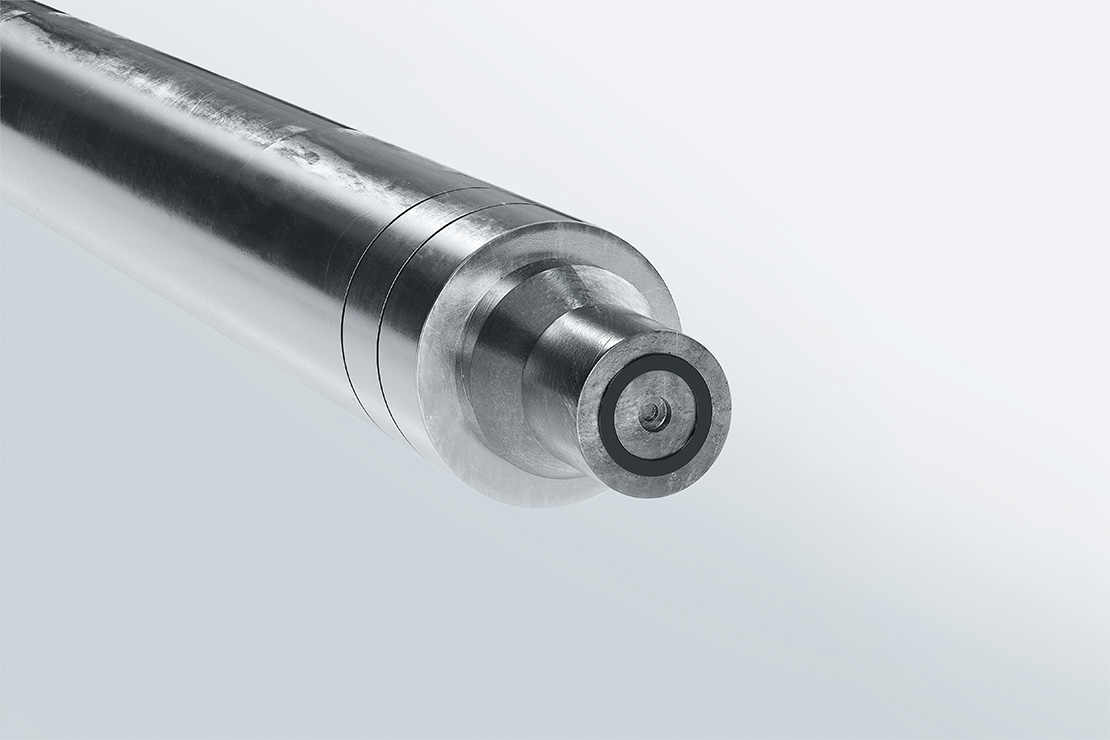

Ignition lance 12 ... 17.2 mm

High energy ignition lance, available in different lance diameters.

Ignition lance 26.7 mm

Extremely durable high energy ignition lance, particularly for flare ignition.

Ignition lance for direct connection to D-HG

Suitable for direct connection to high energy ignition devices in the D-HG x00-5x variants. Flexible lengths and various diameters for configuration of a compact high energy ignition system.

Ignition lances and high-voltage cables

Modular ignition lances in various diameters for safe environments. Flexible lengths of ignition lances and cables for configuration of a separate high energy ignition system.

Ignition tips for D-HG

Suitable for all variants of the D-HG high energy ignition device. Low-wear and flexible in use.